Spraying water intake device and control method

A water inlet device and water inlet pipe technology, which is applied in the field of washing machines, can solve the problems of uneven detergent and affecting the washing effect, and achieve the effect of convenient installation and saving installation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

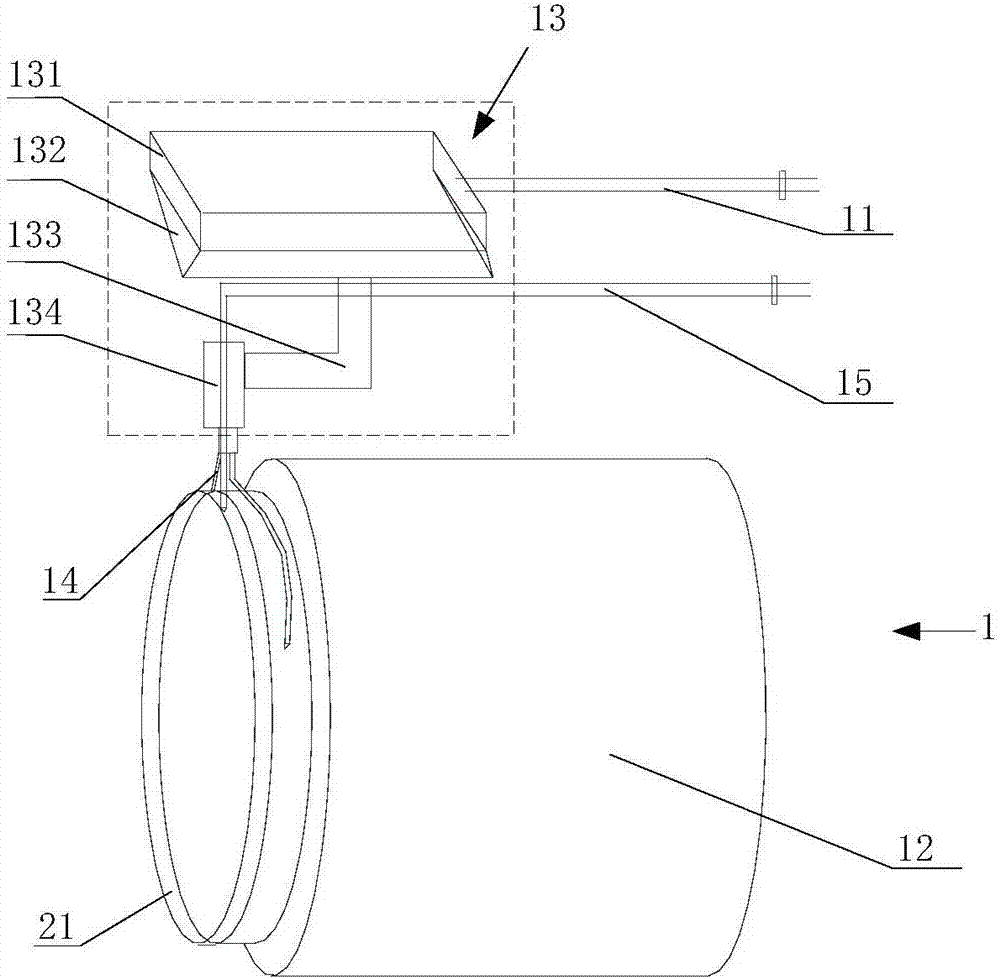

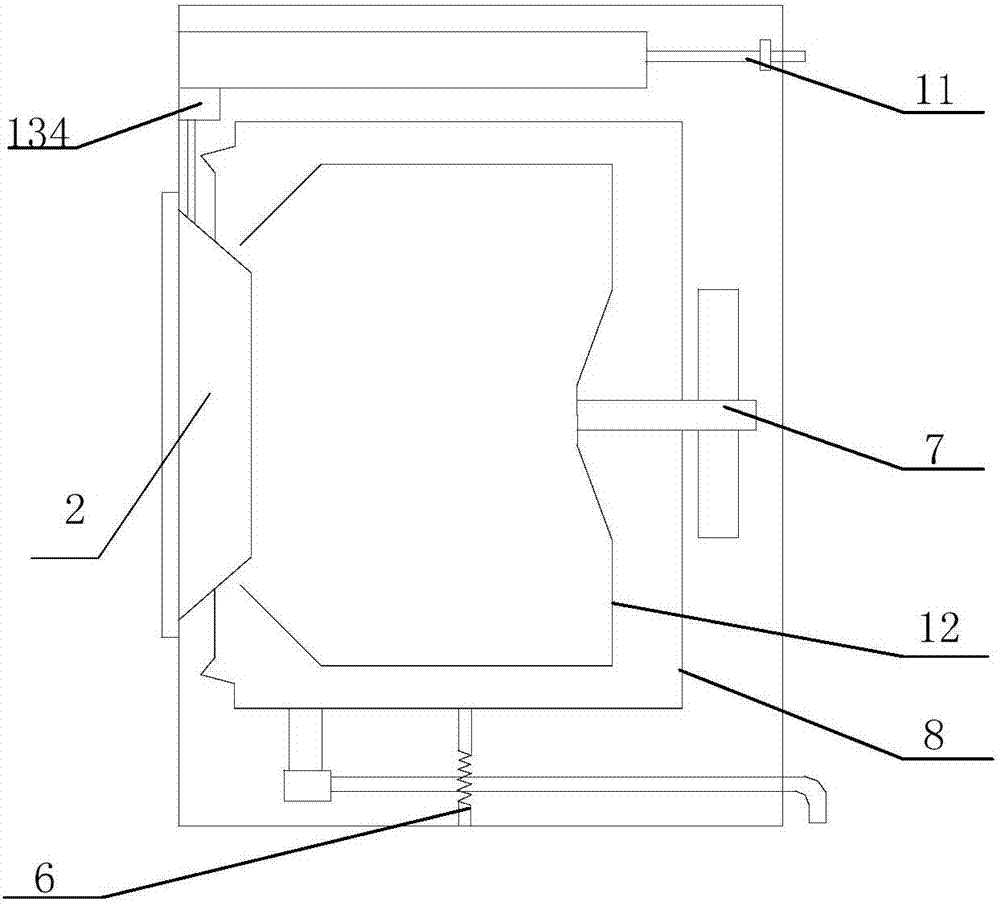

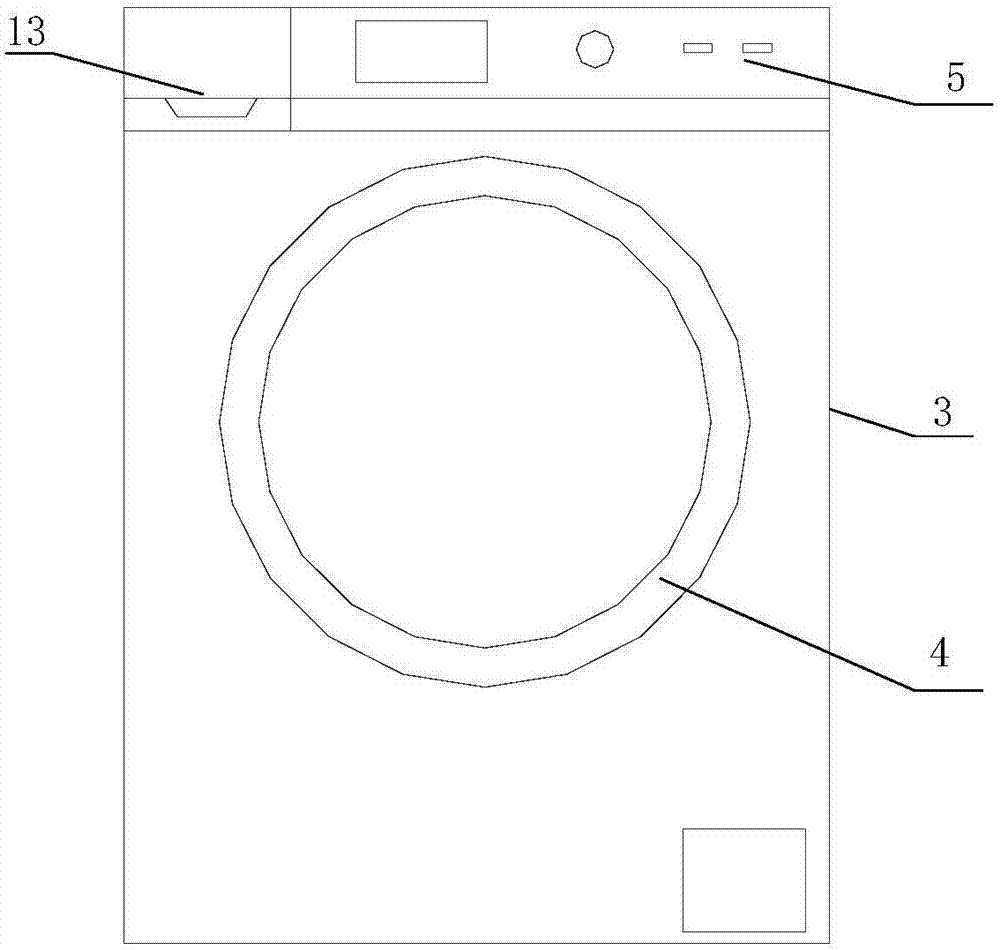

[0048] Such as Figures 1 to 6 As shown, the drum washing machine includes a cabinet 3, and an outer cylinder 8 is arranged in the cabinet 3 to hold washing water. The outer cylinder 8 is supported by a shock absorber 6 to reduce the vibration of the cabinet 3 during washing. The outer cylinder 8 A drum 12 is arranged in the middle, and the drum 12 is used to hold the clothes to be washed, and the drum 12 can be rotated under the drive of the motor 7;

[0049] In addition, a heating wire is arranged inside the bottom of the outer cylinder 8, which can heat the washing water to a set temperature. In addition, a temperature sensor is arranged near the heating wire, which can detect the temperature of the washing water. The cabinet 3 is also provided with a door 4 , used to close the opening of the outer cylinder 8 during washing; the upper right corner of the box body 3 is provided with a distribution system 13, which is used to inject detergent and diluted detergent and spray t...

Embodiment 2

[0070] Such as Figure 7 As shown, a kind of spray water inflow control method that the present invention proposes, comprises the following steps:

[0071] S1, when the washing program is started, the water inlet pipe is opened, and the water flows into the distribution box to dilute the detergent;

[0072] S2, after the diluted washing water flows into the water pump from the outlet pipe, the water pump increases the water pressure of the washing water;

[0073] S3, spray high-pressure washing water into the drum through the spraying branch pipe, and wash after the water inlet is completed;

[0074] S41, when the rinsing program is started after the washing program ends, the water flow enters the drum from the spray branch pipe, and the rinsing is performed after the water intake is completed;

[0075] S51. After the rinsing procedure ends and before the dehydration procedure starts, use the spray branch pipe to rinse the observation window, and then perform dehydration aft...

Embodiment 3

[0077] Such as Figure 8 As shown, a kind of spray water inflow control method that the present invention proposes, comprises the following steps:

[0078] S1, when the washing program is started, the water inlet pipe is opened, and the water flows into the distribution box to dilute the detergent;

[0079] S2, after the diluted washing water flows into the water pump from the outlet pipe, the water pump increases the water pressure of the washing water;

[0080] S3, spray high-pressure washing water into the drum through the spraying branch pipe, and wash after the water inlet is completed;

[0081] S42, when the rinsing program is started after the washing program ends, the water flow enters the drum from the water inlet branch pipe, and the rinsing is performed after the water inlet is completed;

[0082] S52. After the rinsing procedure ends and before the dehydration procedure starts, use the water inlet branch pipe to rinse the observation window, and then perform dehy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com