Windrow scattering assembly of laser leveling machine

A laser leveling machine and decentralized technology, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of increased labor costs and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

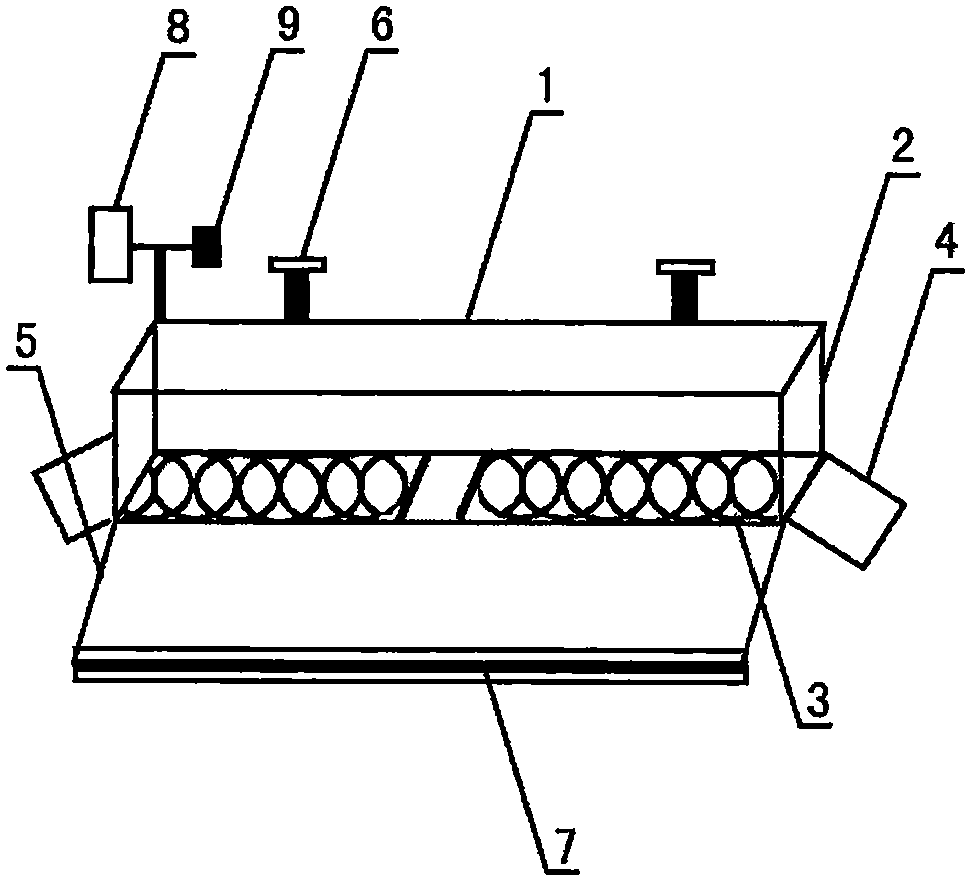

[0012] Embodiment: as shown in the accompanying drawing. A stacking and dispersing component of a laser leveling machine, comprising a body (1), the body (1) is designed as a semi-open rectangular parallelepiped as a whole, and a baffle device (2) and a rotating dispersing platform device (3 ), the outlets on both sides are connected to the blanking device (4), and the lower part of the body (1) is provided with a slope-shaped extension device (5). When in use, the body (1) is installed in front of the scraper of the laser leveler through the fixing device (6). The levelness monitoring device (7) transmits the detection data to the central control device (8) for analysis and regulation, and performs decentralized processing on the stockpiling.

[0013] A stacking and dispersing component of a laser leveling machine is provided with a prompting device (9), and the prompting information is displayed by sound or LED lights.

[0014] A stacking and dispersing component of a laser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com