Reaction device and method for producing methyl propionate

A methyl propionate and reaction device technology, which is applied in the field of reaction devices for the production of methyl propionate, can solve the problems of reducing reaction efficiency and increasing the difficulty of separation steps, and achieves the goals of controlling accumulation, ensuring continuous stability, and realizing recycling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

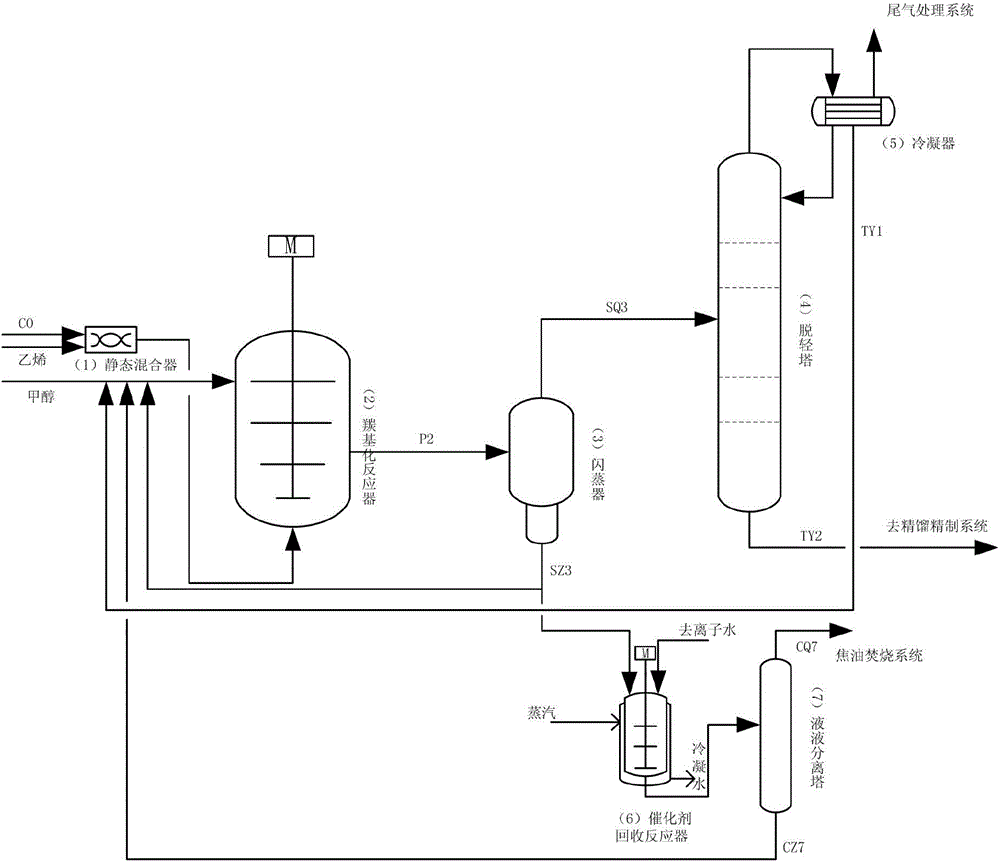

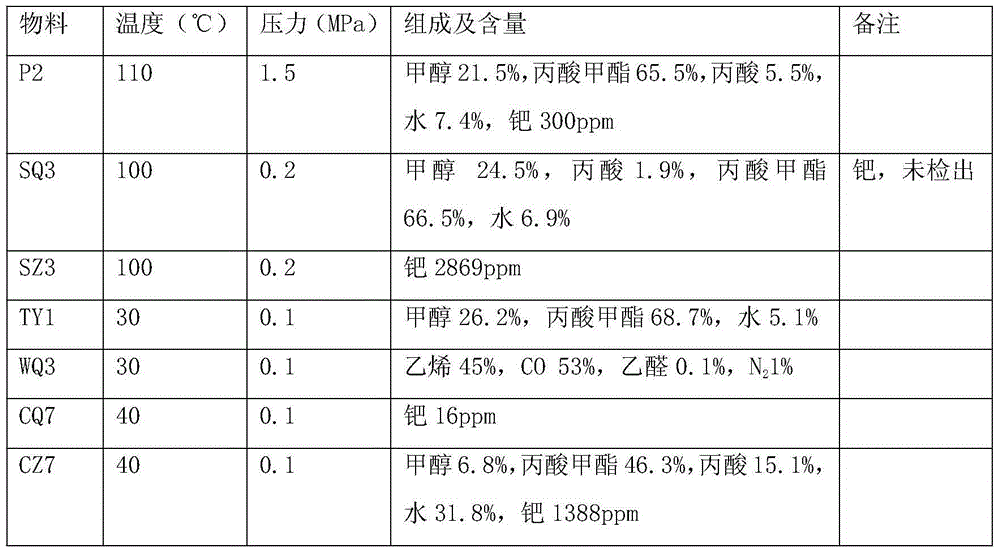

[0025] Such as figure 1 As shown, a reaction device for producing methyl propionate includes a static mixer, a carbonylation reactor and a flash evaporator connected in sequence, the top of the flash evaporator is connected with the light removal tower, and the bottom of the flash evaporator is connected with the catalyst recovery reaction The tail gas from the light removal tower enters the tail gas treatment system after passing through the condenser, and the bottom of the light removal tower is connected with the rectification and refining system; the catalyst recovery reactor is connected with the liquid-liquid separation tower, through the The upper layer material separated by the liquid-liquid separation tower enters the tar incineration system, and the obtained heavy phase returns to the carbonylation reactor. A gas distributor (not shown in the figure) is provided at the bottom of the carbonylation reactor.

[0026] For a schematic diagram of the process flow, see fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com