Motor, activation control method for motor, and fan including motor

A motor and fan technology, applied in the direction of electronic commutation motor control, program control, control system, etc., can solve the problems of the motor starting not smoothly, starting dead angle, unable to automatically adjust the starting force, etc., so as to improve the starting smoothness and reduce the complexity. degree and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the above and other purposes, features and advantages of the present invention more comprehensible, the preferred embodiments of the present invention are specifically cited below, together with the accompanying drawings, as follows:

[0027] Directional terms such as "front", "rear", "left", "right", "upper (top)", "lower (bottom)", "inner", "outer", " "side" and so on are mainly referring to the directions of the accompanying drawings, and the directional terms are only used to assist in explaining and understanding various embodiments of the present invention, and are not intended to limit the present invention.

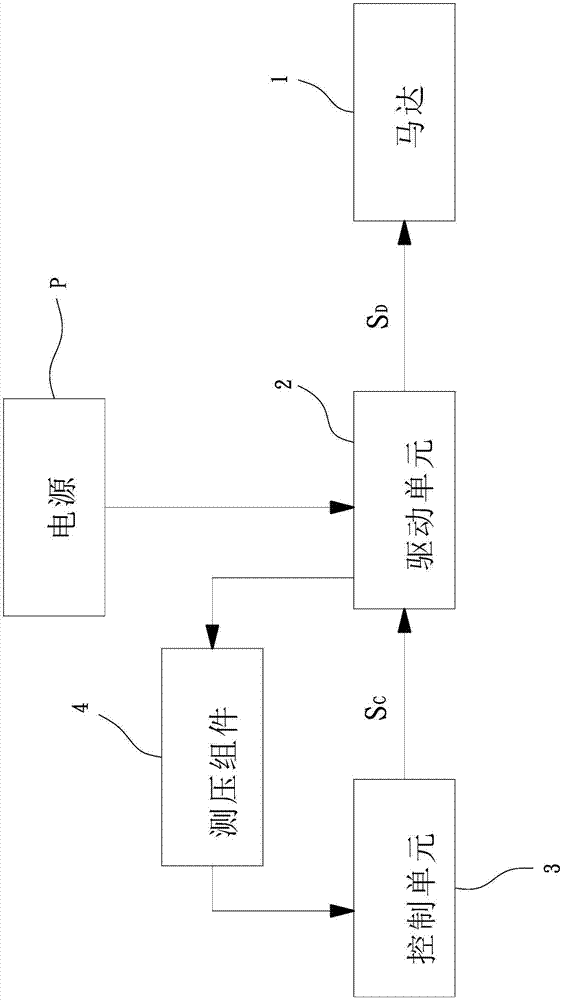

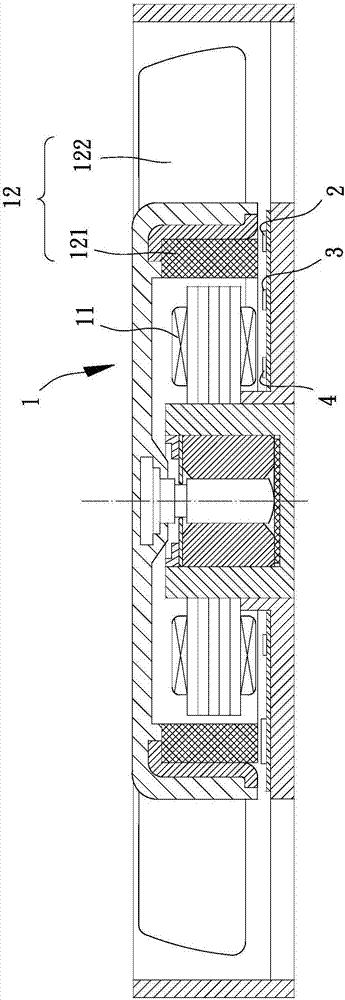

[0028] see figure 1 and figure 2 As shown, it is a schematic block diagram and a combined cross-sectional view of a motor embodiment of the present invention applied to a fan. Wherein, the motor 1 can be used as a power output source of a fan or other electric devices. Taking a fan as an example, the fan can include: the motor 1 and a dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com