Vibrating sieve device for combine harvester

A technology of combine harvester and vibrating device, which is applied in agricultural machinery and implements, threshing equipment, applications, etc., can solve the problems of inability to realize screen replacement, inconvenient screening of material discharge, etc., and achieve convenient screen replacement, rapid screening, good filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

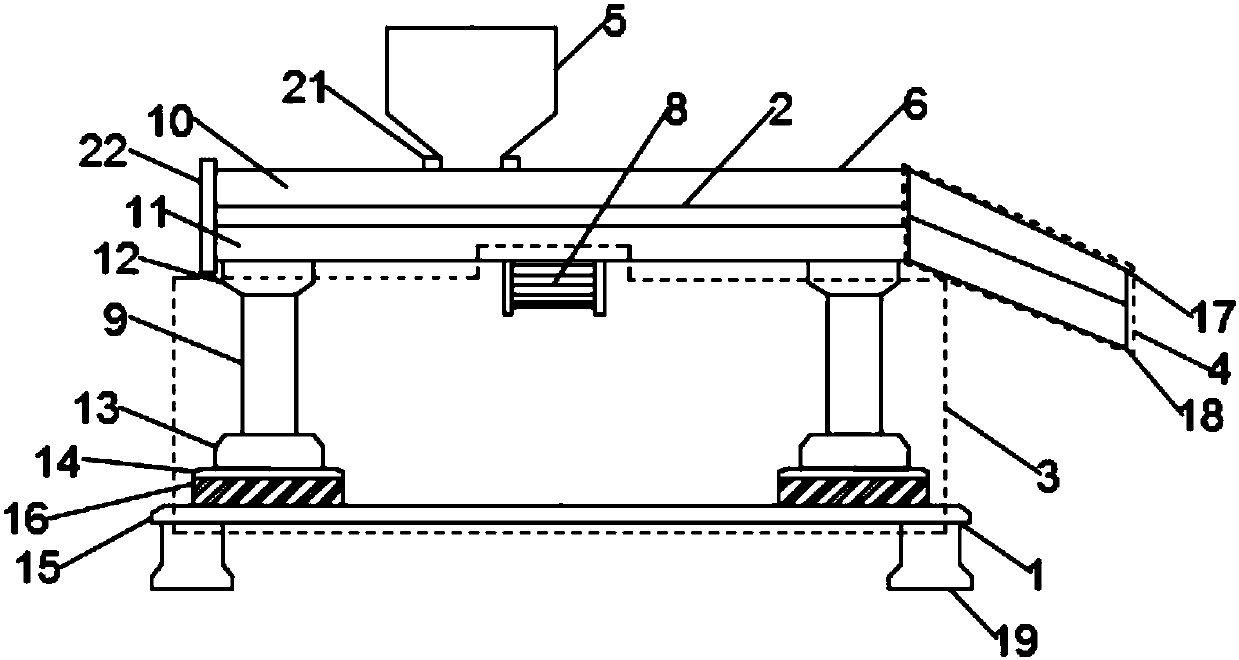

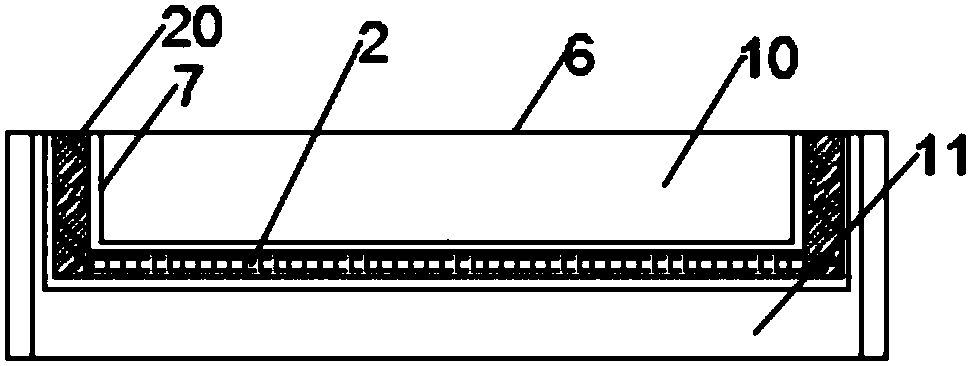

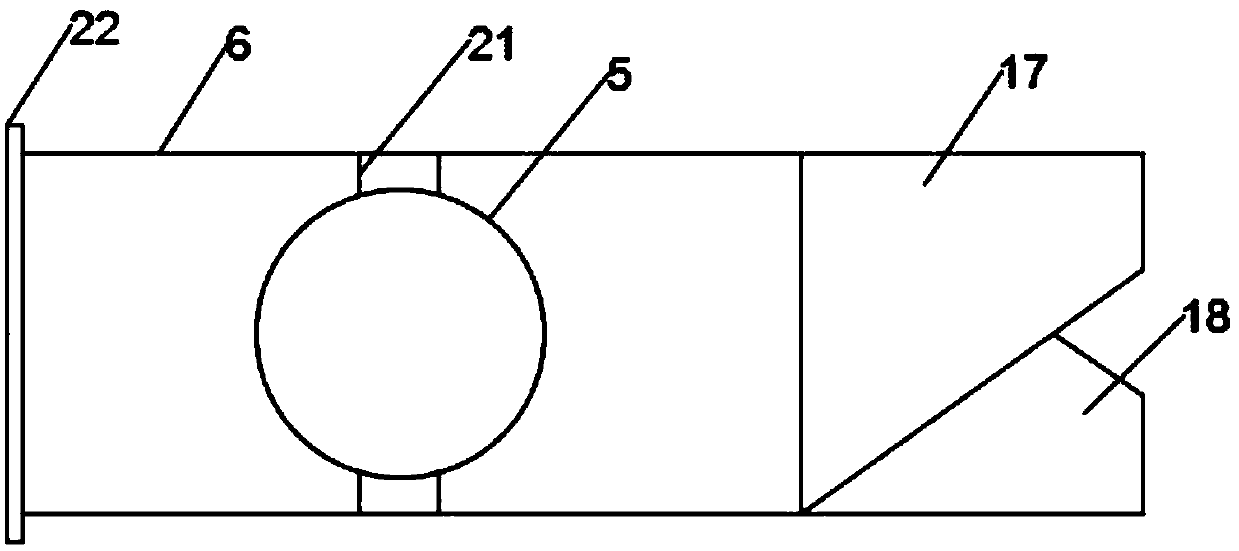

[0021] Such as figure 1 , figure 2 with image 3 As shown, the present invention proposes a technical scheme: a vibrating screen device of a combine harvester, comprising a support frame 1, a screen 2, a vibrating device 3, a discharge device 4 and a feed hopper 5, and the screen 2 passes through The metal frame 6 on the surface is fixed, and the side of the metal frame 6 is provided with an annular groove 7, and the screen 2 is fixed inside the metal frame 6 through the groove 7, and the screen 2 divides the inside of the metal frame 6 into Screening chamber 10 and discharge chamber 11, described screening chamber 10 is positioned at the top of discharge chamber 11, described vibration device 3 comprises vibration motor 8 and hydraulic rod 9, and described vibration motor 8 is installed in metal frame 6 bottoms, so The bottom corners of the metal frame 6 are equipped with hinged seats 12, and the metal frame 6 is hinged together with the hydraulic rod 9 through the hinged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com