Roller pelletizer for sludge ceramsite granulation

A sludge ceramsite and granulator technology, applied in the field of counter-roll granulators, can solve the problems of easy adhesion in the groove, affecting the granulation efficiency, and easy to overload, so as to improve the utilization efficiency and overload damage. The effect of saving energy and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be further specifically described below through specific embodiments and accompanying drawings, but the present invention is not limited to these embodiments.

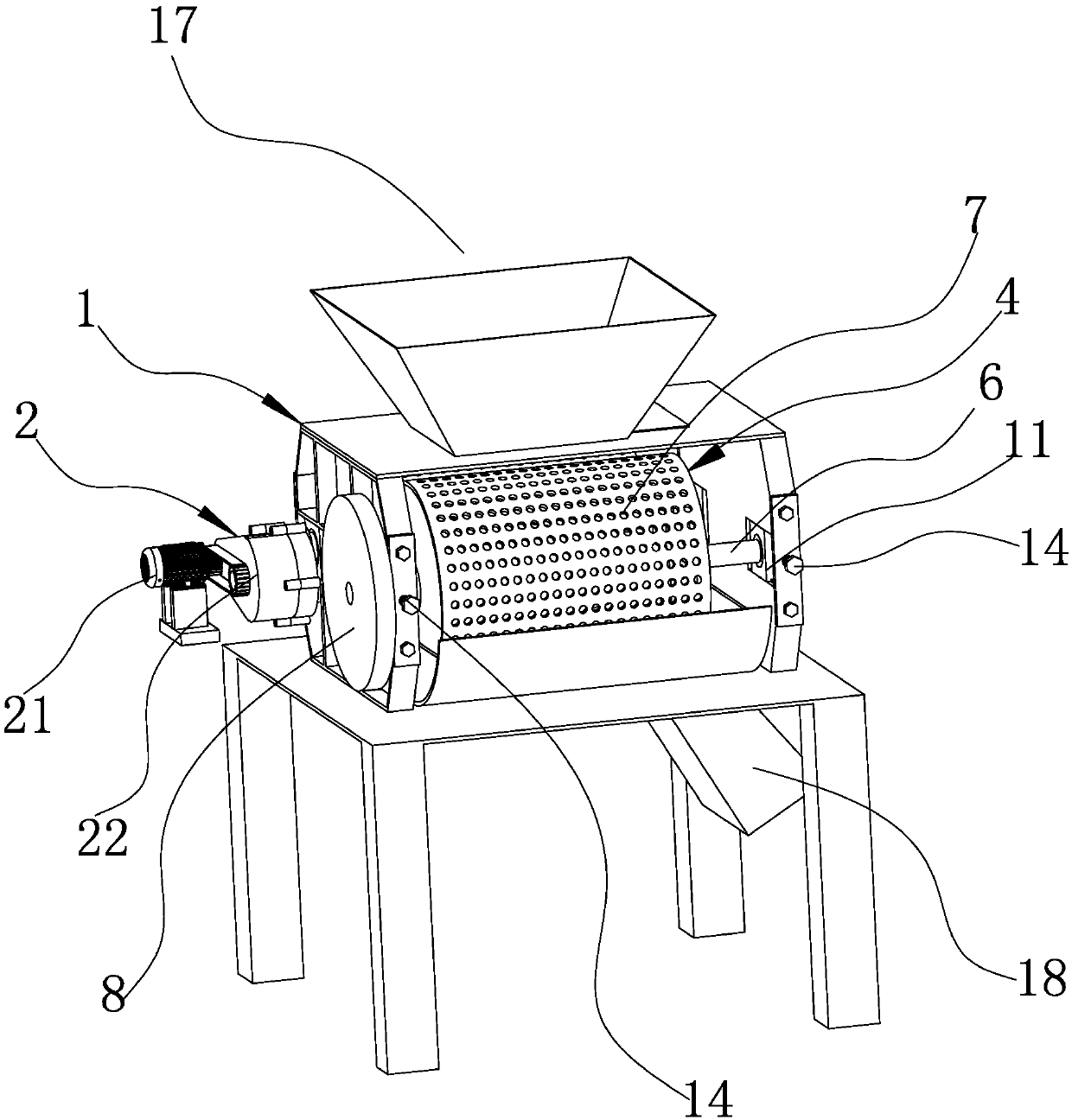

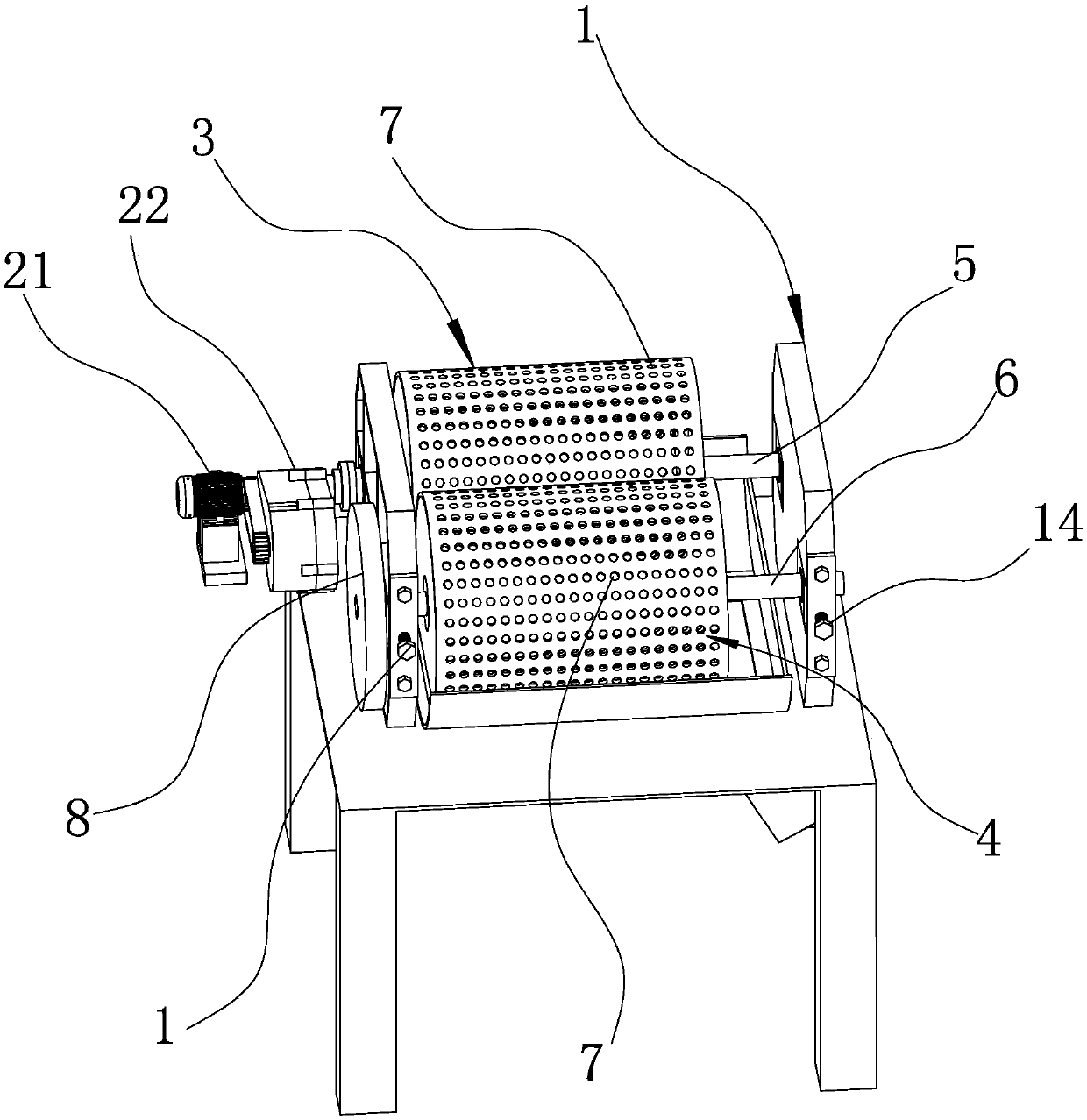

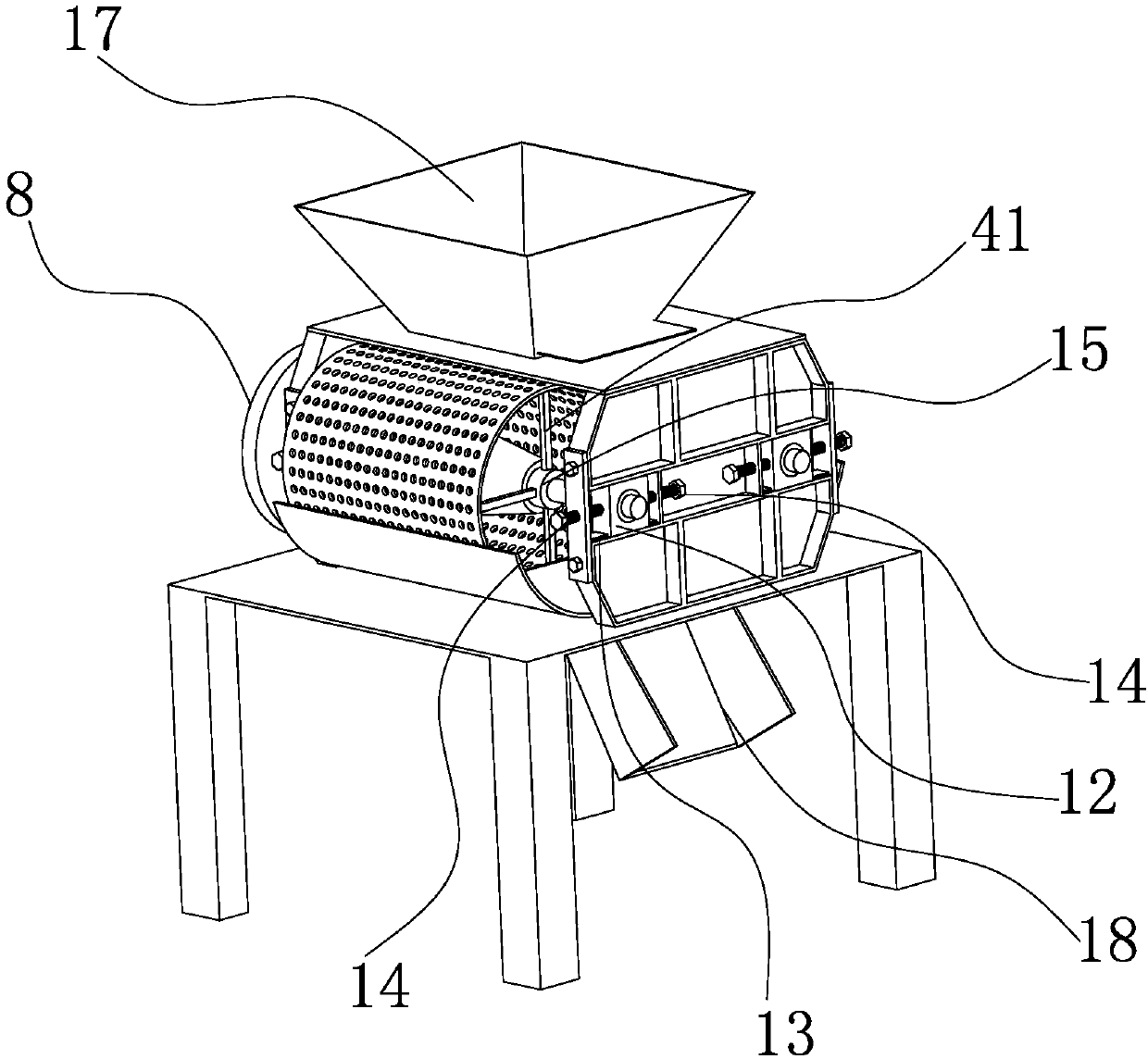

[0027] Such as Figure 1-7 As shown, the double-roll granulator used for sludge ceramsite granulation includes a frame 1, a driving mechanism 2, a driving roller 3 and a driven roller 4, and the driving roller 3 is rotatably installed by a rotating shaft 5 On the frame 1, it is generally directly fixed on the shaft 1 through the bottom of the driving roller 3, and the driven roller 4 is rotatably installed on the frame through the shaft 2 6, and generally directly passes through the driven roller 4. The bottom of the cylinder is directly fixed on the rotating shaft 6; the driving roller 3 and the driven roller 4 are arranged horizontally, which is equivalent to making the driving roller 3 and the driven roller 4 in the front and rear opposite positions, and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com