Material color code spraying device of sulfur and hydrogen resisting bent pipe fitting material

A technology for spraying devices and pipe fittings, which is applied in spraying devices, liquid spraying devices, and devices for coating liquid on surfaces, etc., can solve problems such as inability to use, affect oil quality, and leak and pollute the environment, and reduce labor costs and design. Reasonable and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

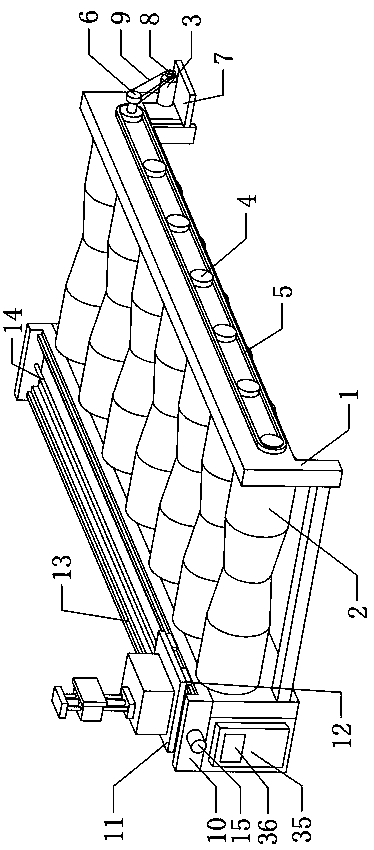

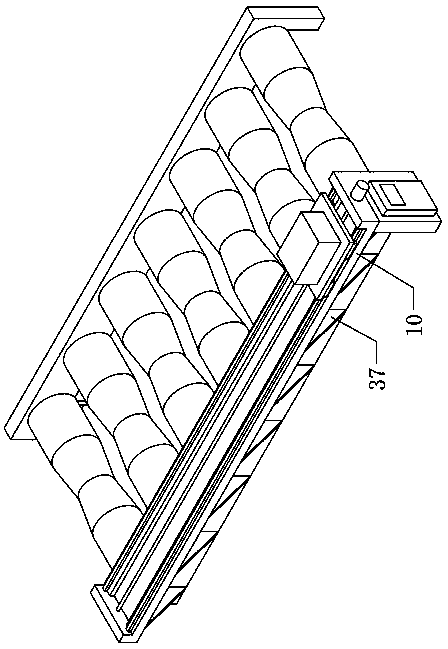

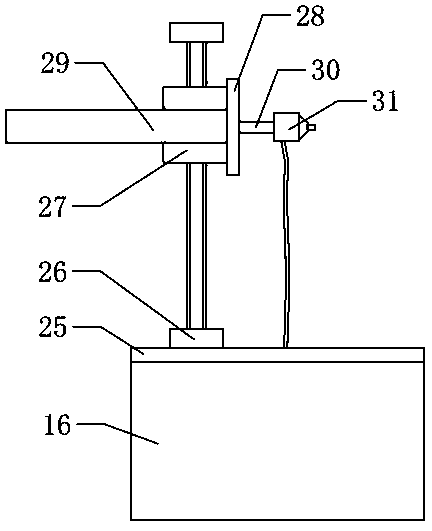

[0032] As shown in the figure, a material color code spraying device for anti-sulfur and anti-hydrogen elbow pipe fitting materials includes a frame 1, a feeding mechanism, a sliding mechanism, a spraying mechanism and a control mechanism. The feeding mechanism for conveying, the feeding mechanism includes a plurality of feeding rollers 2 installed in the middle of the frame 1 and arranged parallel to each other and a drive motor 3 installed on the side of the frame 1, and the outer surface of the frame 1 is provided with a A plurality of sprockets 4, the sprockets 4 are connected by chains 5, a driven wheel 6 is connected to the sprocket 4 at the end of the frame 1 through a transmission shaft, the side of the frame 1 is provided with a motor mounting plate 7, the motor The top of the mounting plate 7 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com