Electric hammer punching balancing support

A technology of balancing bracket and electric hammer, applied in the fields of civil engineering and machinery, can solve the problems of inconvenience and easy fatigue of moving the ladder, and achieve the effect of saving physical strength, easy operation and efficient production operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings. The same components in each drawing are represented by the same reference numerals.

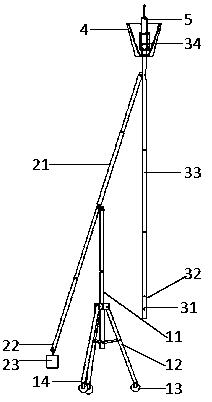

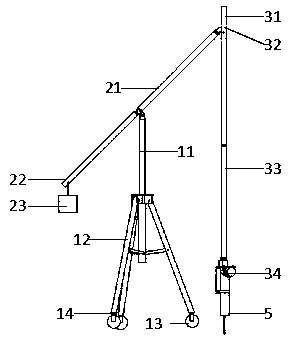

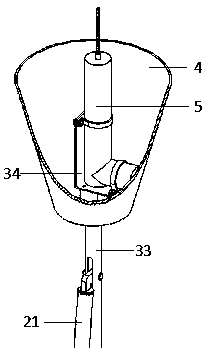

[0020] Such as figure 1 As shown; the electric hammer punching balance bracket is composed of a support part, a balance part, a clamping part, and a dust collection device, wherein the support part is composed of a telescopic or movable connection support rod 11, a tripod or a trivet 12, and a universal wheel 13 , anti-slip device 14; the balance part is composed of a balance bar 21, a counterweight fixed fulcrum 22, and a counterweight 23; Or the electric hammer fixed bracket 34 is formed, and the dust collection device is made up of inverted funnel type dustproof cover 4, and wherein telescopic or movable connection support bar 11 is fixed on the tripod o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com