Method for preventing chippings from being pasted to stirring device

A mixer and sticky technology, which is applied in the direction of chemical instruments and methods, cement mixing devices, clay preparation devices, etc., can solve the problems of uneven wall surface and increase the repair time of the wall surface, so as to prevent sticky debris, increase the Cleans up time, increases stability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

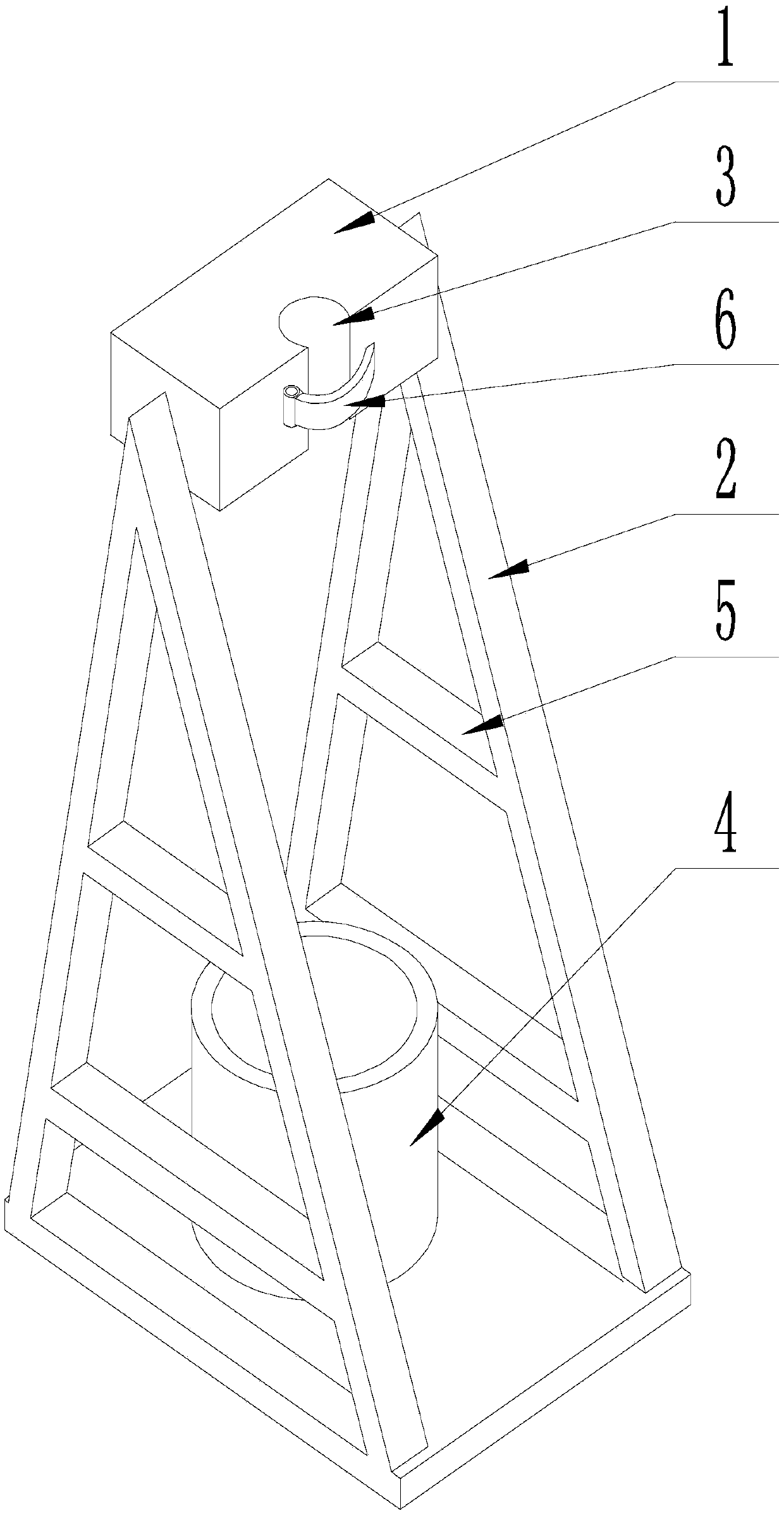

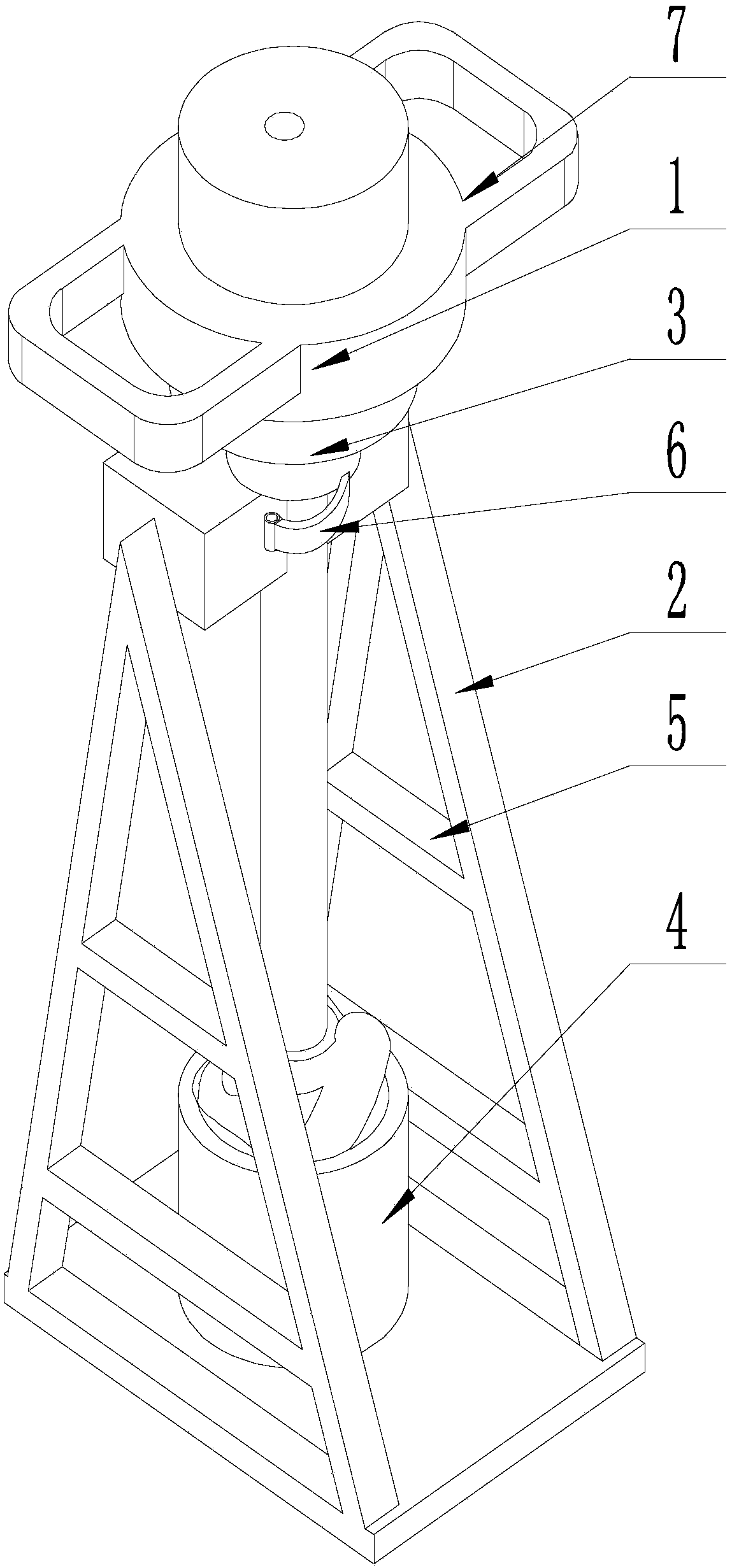

[0033] like Figure 1-Figure 2 Shown, the present invention prevents the method for agitator sticky chip, comprises the steps:

[0034] Step A Preparation: Fix the support block 1 above the ground through the support, and place the storage tank 4 under the support block 1;

[0035] Step B fixation: place the stirring part of the agitator in the bucket 4, and the rotating shaft of the agitator snaps into the installation groove 3 on the support block 1;

[0036] Step C limit: rotate the limit plate 6 so that the rotation axis is located between the bottom of the installation groove 3 and the limit plate 6 .

[0037] After the agitator has mixed the raw materials, pick it up from the bucket, and then place it on the support block 1, and make the stirring part of the agitator located in the storage bucket 4, and the rotating shaft of the agitator is stuck in the through groove I3, and the agitator The holding part of the mixer is in contact with the top of the support block 1; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com