Plastic rolling machine with variable volume heating chamber

A technology of heating chamber and rotational molding machine, applied in the direction of coating, etc., can solve the problems of waste of funds, idle equipment, increase of production costs, etc., and achieve the effects of saving space, reducing energy consumption, and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

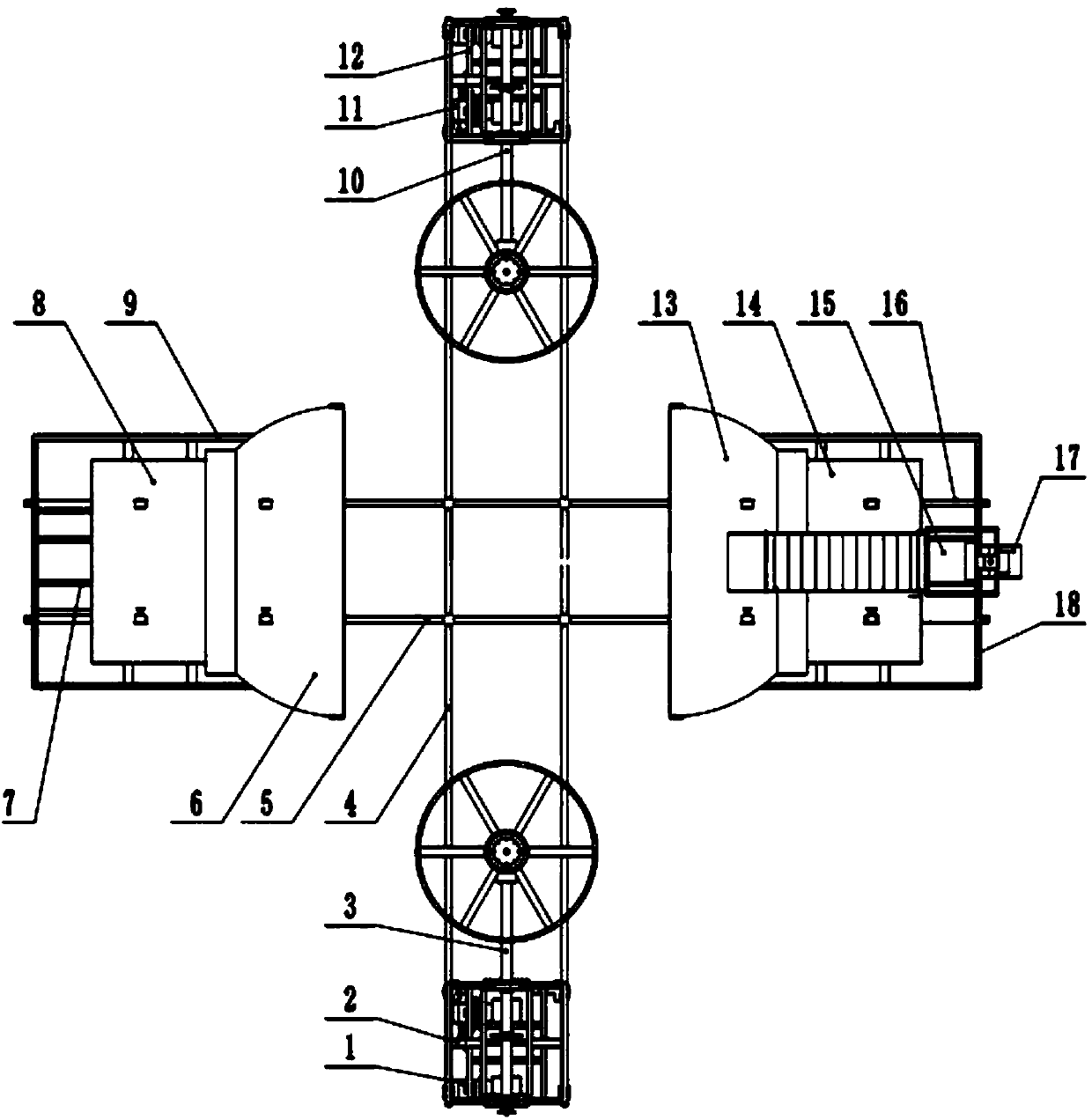

[0009] Embodiment 1, referring to the accompanying drawings, a rotomolding machine with a variable heating chamber volume, including a work arm sliding guide 4, a front station work arm 10, a rear station work arm 3, and the front work station work arm 10 is set On the front station trailer driving device 12, the rear station arm 3 is arranged on the rear station trailer driving device 2, and the front station trailer driving device and the rear station trailer driving device 2 are respectively arranged on The front and rear of the working arm sliding guide 4 can be displaced forward and backward relative to the working arm sliding guide 4, and it is characterized in that it also includes a heating chamber sliding guide 5 crossing the working arm sliding guide 4, the The left side of the heating chamber sliding guide rail 5 supports the large left heating chamber trailer driving device 9 and the small left heating chamber trailer driving device 7, and the large left heating cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com