Low-pressure chemical foaming injection mold of automobile inner plate and forming method thereof

A technology of low-pressure chemistry and injection molding, which is applied to household appliances, other household appliances, household components, etc., can solve the problems of high internal stress, mixing, and high equipment investment costs in products, so as to reduce production costs, increase product strength, and improve surface quality. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

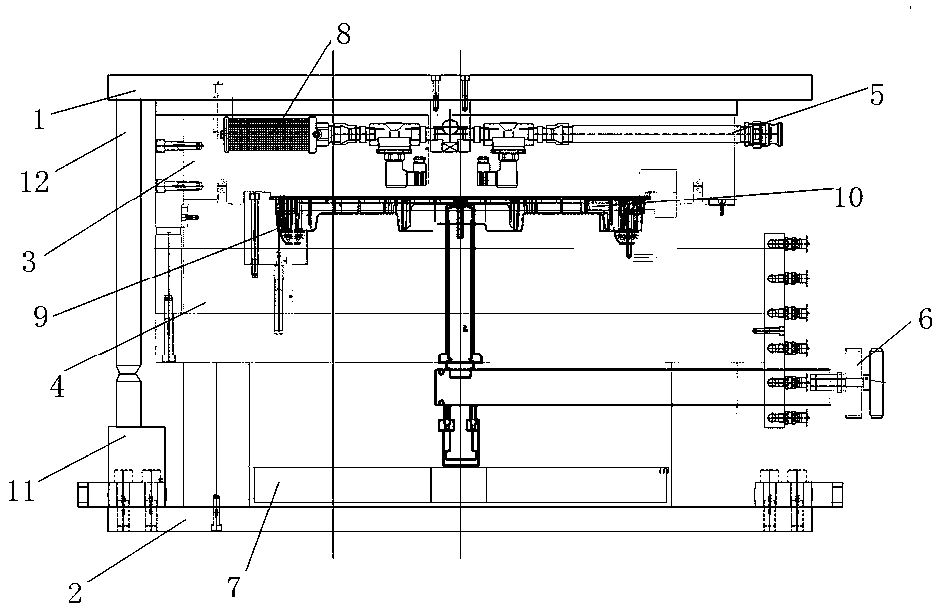

[0029] Such as figure 1 Shown, a kind of low-pressure chemical foaming injection mold of automobile inner panel, other comprises upper mold bottom plate 1, lower mold bottom plate 2, upper mold 3, lower mold 4, gas storage tank 5 and hot runner 6; Said upper mold 3 installs On the upper mold bottom plate 1, the lower mold 4 is installed on the lower mold bottom plate 2, and a mold cavity 9 is formed between the upper mold 3 and the lower mold 4, and the mold cavity 9 communicates with the gas storage tank 5, and the mold cavity The side wall of 9 is provided with a sprue, and the mold cavity 9 communicates with the hot runner 6 through the sprue; a mold lifting cylinder 11 is also installed on the bottom plate 2 of the lower mold, and the output end of the lifting mold cylinder 11 is connected to the mold lifting One end of the top block 12, the other end of the lifter top block 12 is connected to the upper mold bottom plate 1, and is used to control the lifting of the upper m...

Embodiment 2

[0032] Use the injection mold described in Example 1 to carry out the product molding operation, specifically: when injecting plastic particle polypropylene (PP+glass fiber), first inject a plastic volume of 2.0t, and then press and release it precisely through the equipment, and rise to 3.5t is foam filled to achieve light weight and high precision strength. When the pressure reaches 0.8-2.0MPa, the molten mixture of plastic particles and foaming agent (barrel temperature is 260 degrees Celsius) is injected into the mold cavity (the upper mold is closed and the lower mold is injected) for a period of time (5- 10S), at the same time, the gas in the mold is slowly discharged through the vent hole, and then the upper mold plate of the mold clamping mechanism moves backward for a certain distance (the moving distance is set as the thickness of the product, and the thickness of the inner plate is 3mm), so that the lower mold of the mold Separate from the upper mold, extend the par...

Embodiment 3

[0034] The injection mold in the first embodiment and the injection molding method in the second embodiment are used for specific applications.

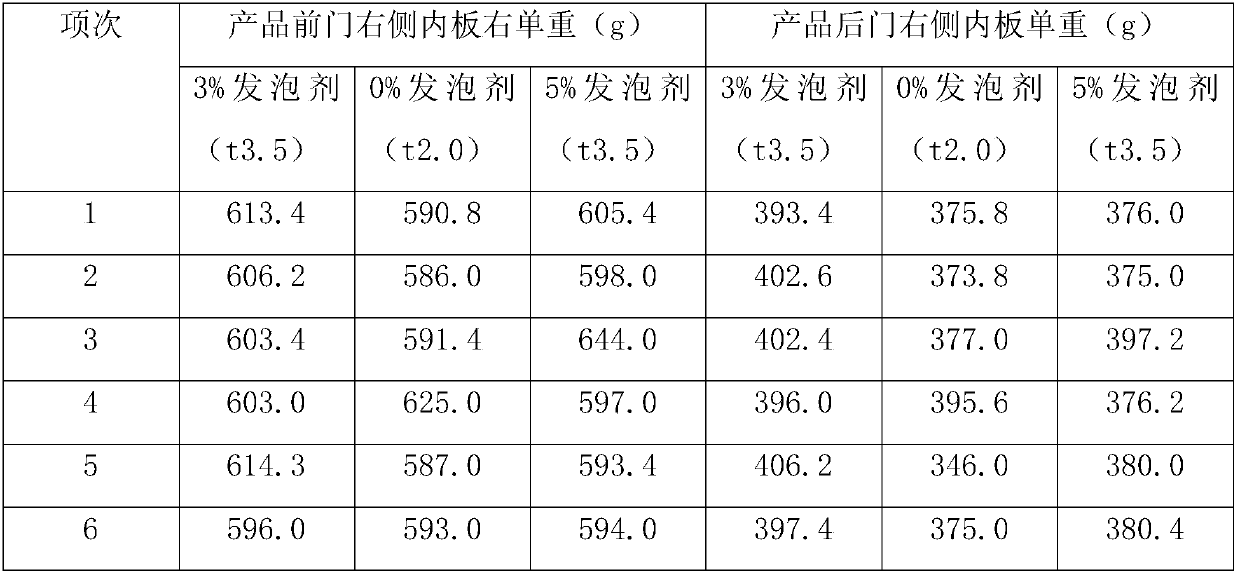

[0035] Example: The door inner panel of a certain brand of automobile is used as the development and production verification, and the thickness of the trial product without foaming agent is t2.0mm (the following data sources are trial weight data)

[0036]

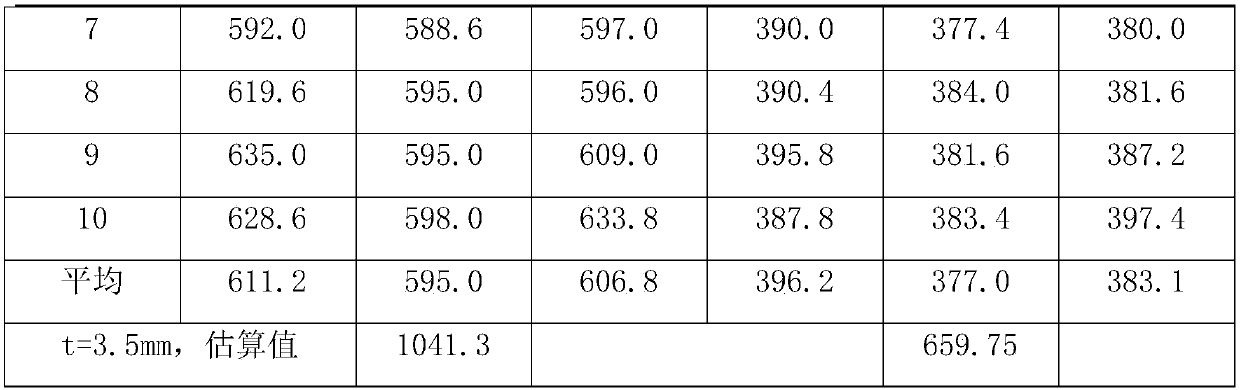

[0037]

[0038] ①The average weight of the inner panel on the right side of the front door without foaming agent is 595g, and t=2.0mm. When t=1.0mm, the estimated unit weight is 595 / 2=297.5g. When t=3.5mm, the estimated unit weight is 297.5*3.5=1041.25g, weight loss: 441g.

[0039] ②The average weight of the rear right inner panel without foaming agent is 377g, t=2.0mm, then the estimated unit weight is 377 / 2=188.5g when t=1.0mm, and when t=3.5mm, calculate the tentative list The weight is 188.5*3.5=659.75g, and the weight loss is 259g.

[0040]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com