Leg crawler type liftable stepping chassis for engineering machinery and method for controlling leg crawler type liftable stepping chassis

A technology of construction machinery and chassis, which is applied in the field of leg-type liftable stepping chassis and its control field, can solve the problems of inability to guarantee the passage of construction vehicles, inability to fully play a role, etc., and achieve the effect of improving passability and flexible relative movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0080] In order to further illustrate the technical solution of the present invention, in conjunction with the accompanying drawings, the specific implementation of the present invention is as follows:

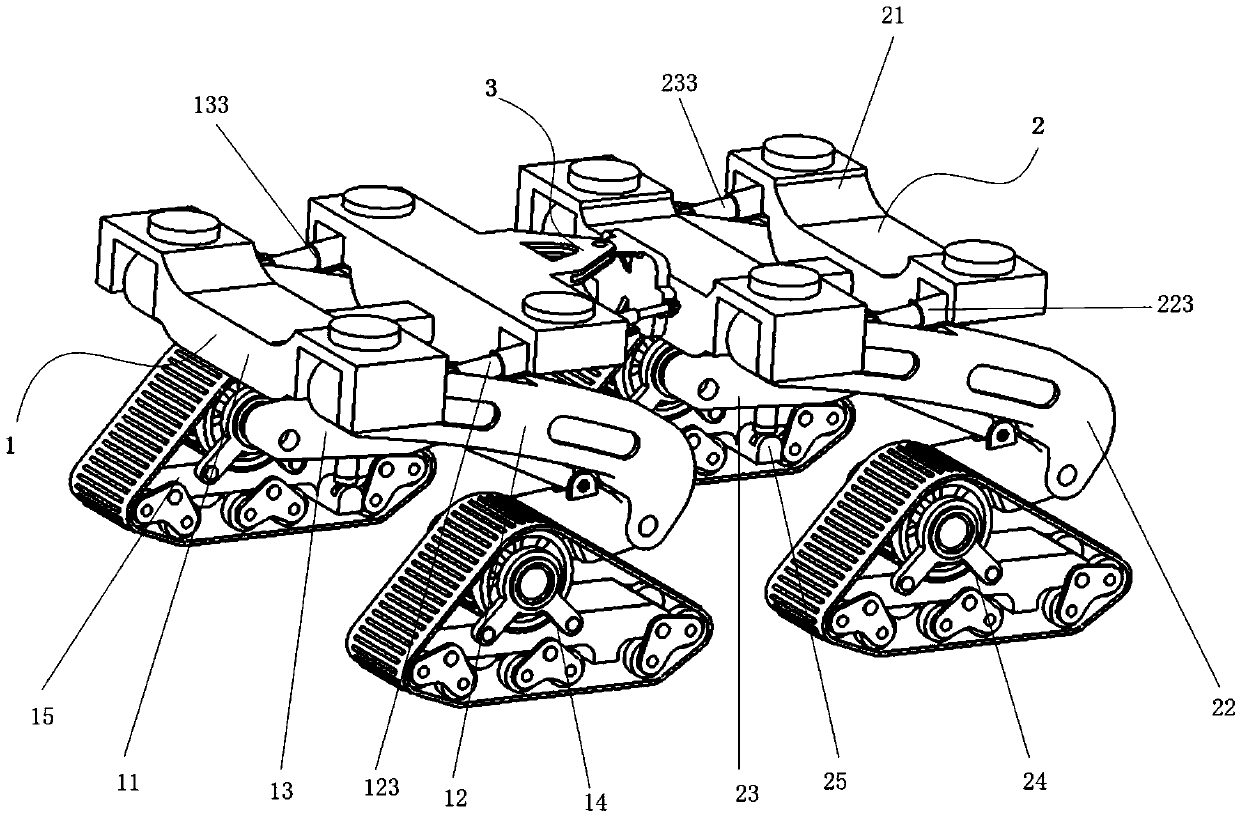

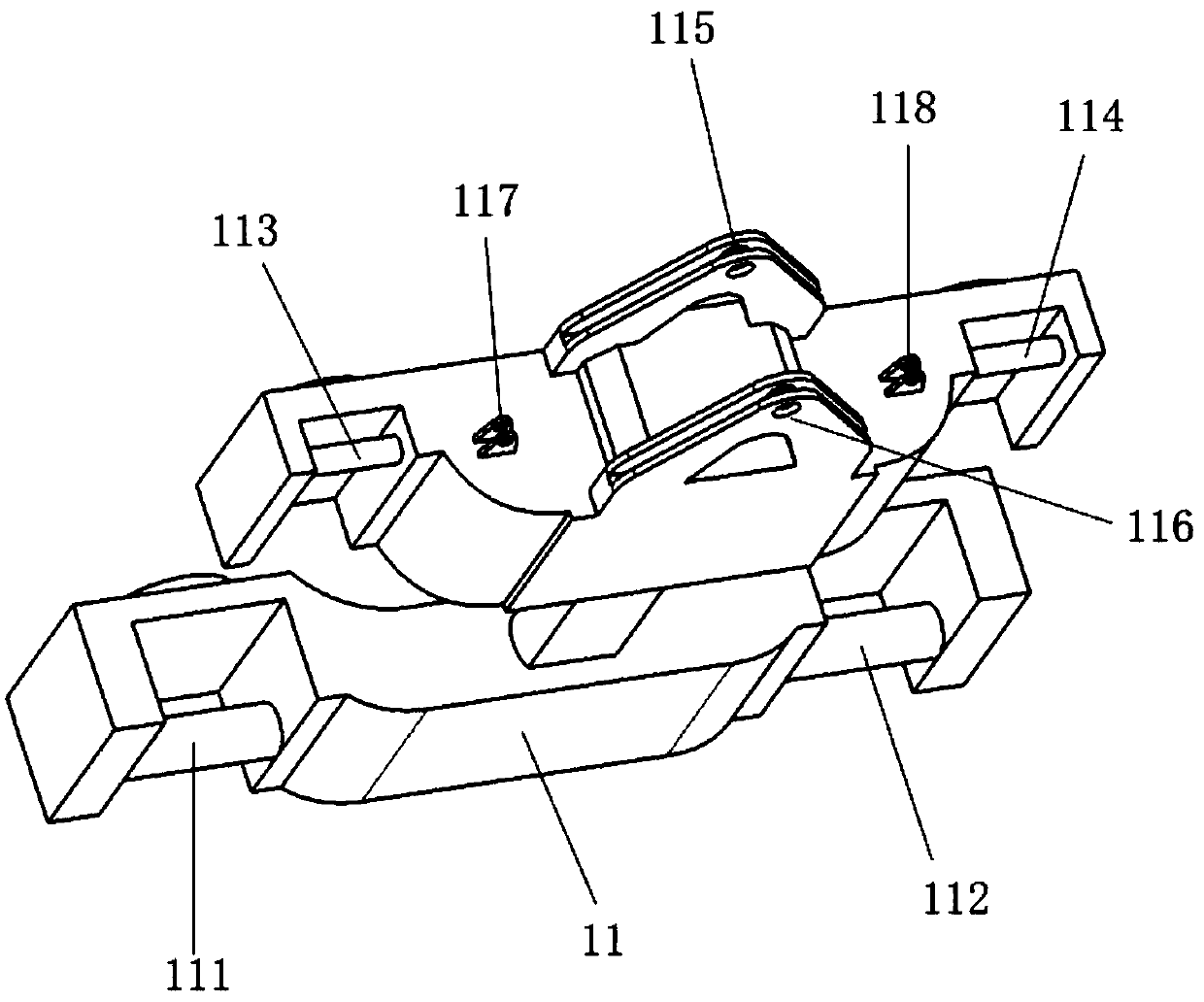

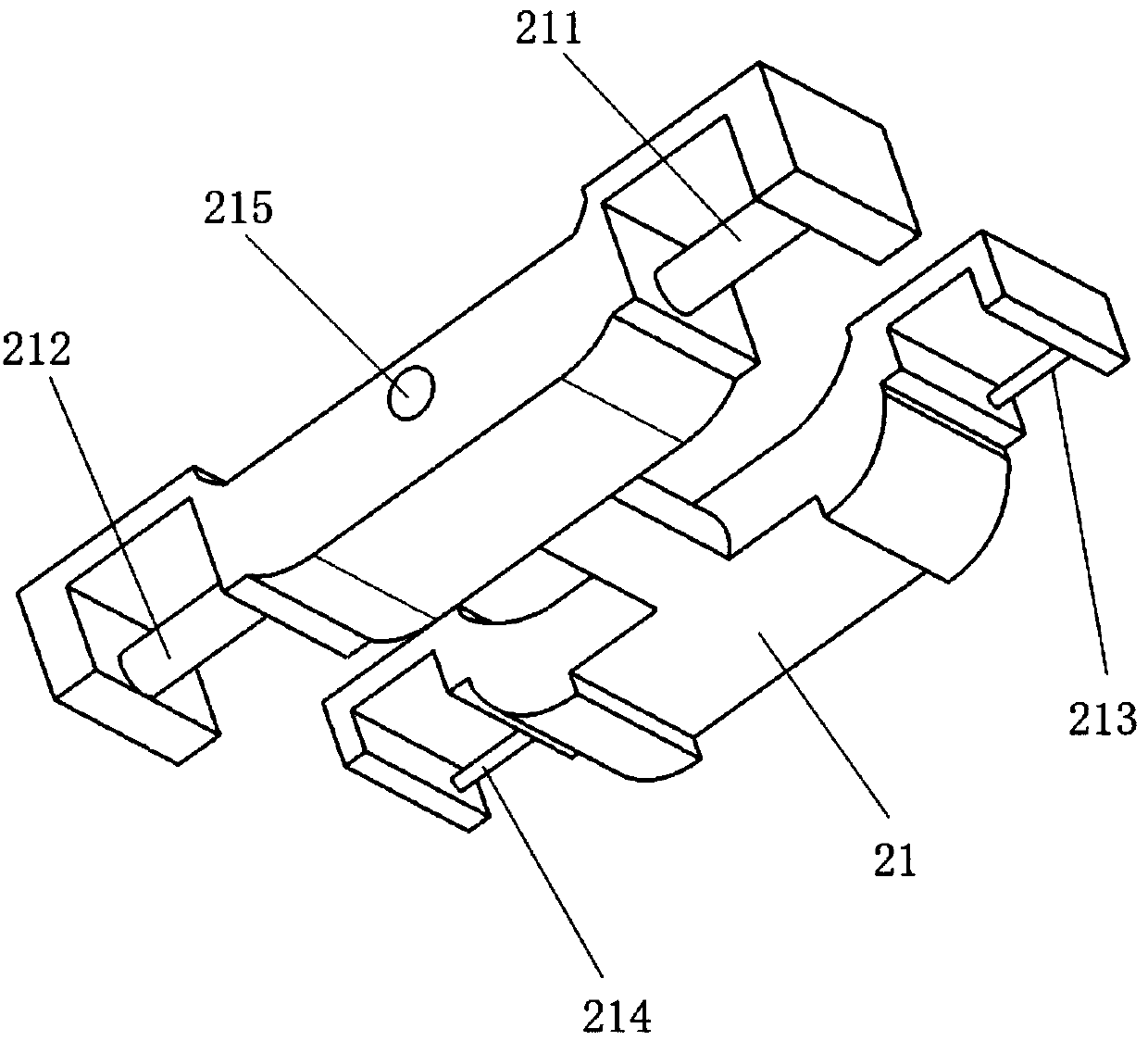

[0081] Such as figure 1 As shown, the present invention provides a leg-type liftable walking chassis for engineering machinery, the chassis is composed of a front body 1, a rear body 2 and a dual-degree-of-freedom articulated steering device 3; the dual-degree-of-freedom The articulated steering device 3 is connected between the vehicle body 1 and the rear vehicle body 2. The yaw degree of freedom of the two-degree-of-freedom articulated steering device 3 can ensure that the engineering vehicle can complete the function of the articulated steering, and the degree of freedom of the roll can ensure that the engineering vehicle can pass through the rugged It has better stability on the road surface; the front car body 1 is composed of a front chassis 11, a leg type telescopic sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com