Modification method of rubber particles and application thereof in preparing natural pumecrete

A technology of rubber particles and concrete, applied in the field of building materials, can solve problems such as reducing the compressive strength of concrete, and achieve the effects of improved compressive strength, good mechanical properties and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

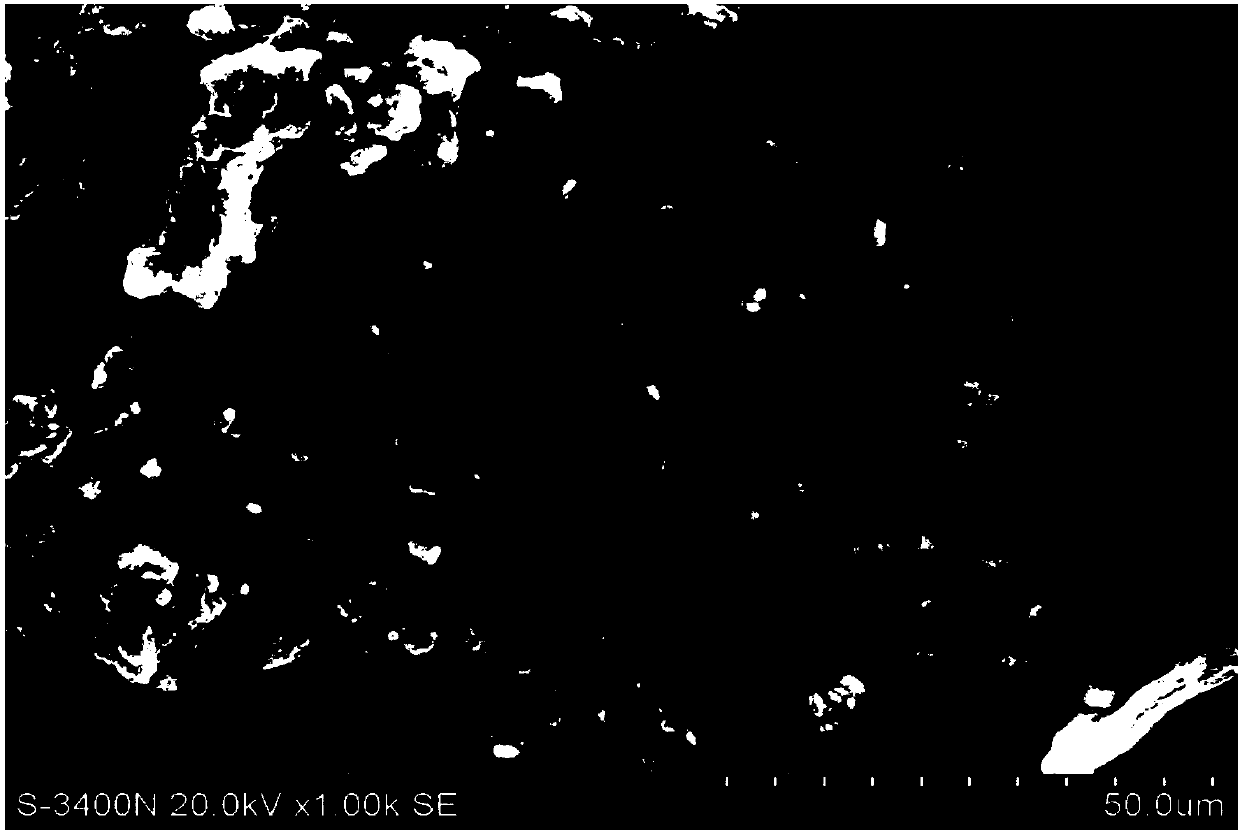

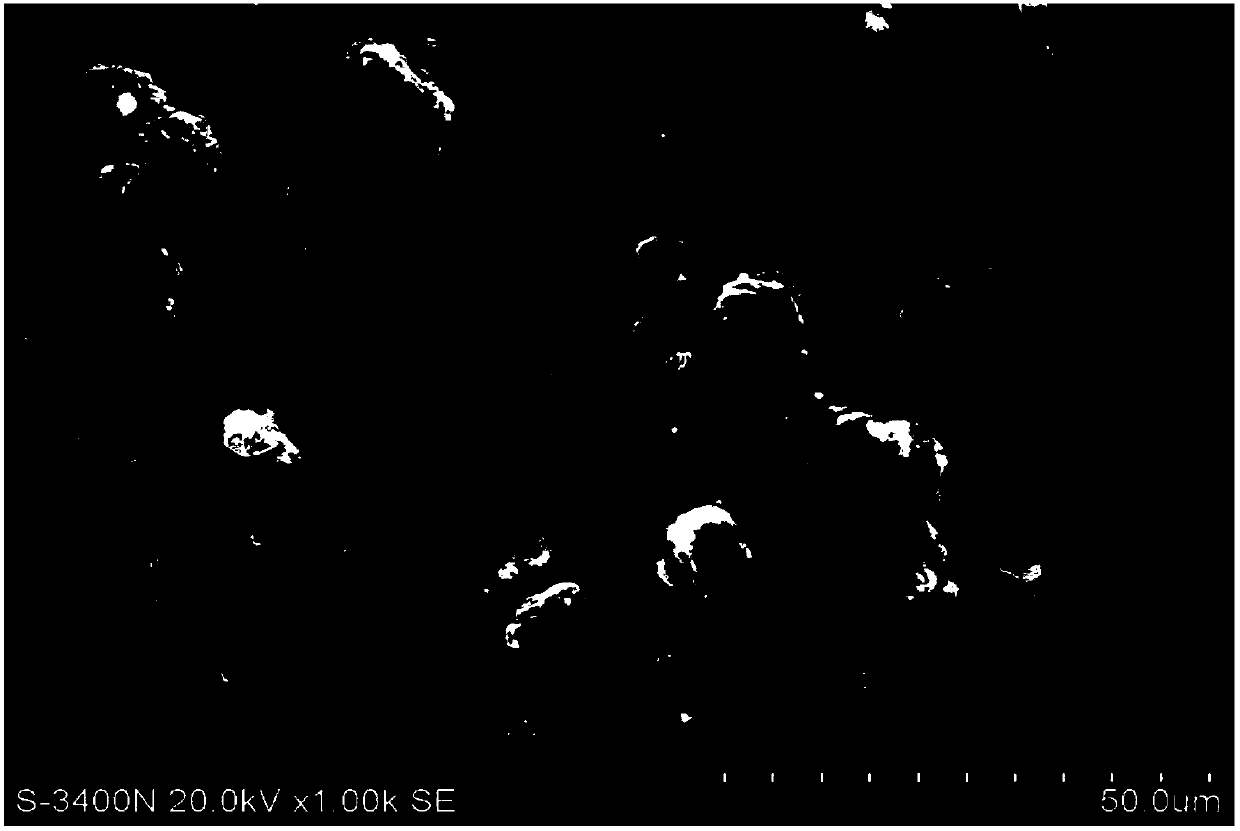

Image

Examples

Embodiment 1

[0029] A method for modifying rubber particles, specifically implemented according to the following steps:

[0030] Step 1, prepare a modified solution by mixing Span 40 with a mass concentration of 1% and water at 100°C in a mass ratio of 1:10;

[0031] Step 2, immerse the rubber particles with a particle size of 80 mesh into the modified solution prepared in step 1, and stir at a speed of 30r / min for 120min, after the stirring is completed, let stand for 3h, and filter after standing to obtain wet modified rubber Particles, the wet modified rubber particles are naturally dried and sieved to obtain the modified rubber particles, and the modified rubber particles are sealed and stored for future use.

[0032] The modified rubber particles prepared above are used to prepare natural pumice concrete, specifically according to the following steps:

[0033] Step 1, weighing 3500 parts of cement, 700 parts of river sand, 550 parts of natural pumice, 150 parts of water, 7 parts of w...

Embodiment 2

[0039] A method for modifying rubber particles, specifically implemented according to the following steps:

[0040] Step 1, prepare a modified solution by mixing Span 40 with a mass concentration of 1% and water at 100°C in a mass ratio of 1:10;

[0041] Step 2, immerse the rubber particles with a particle size of 80 mesh into the modified solution prepared in step 1, and stir at a speed of 30r / min for 100min, after the stirring is completed, let stand for 4 hours, and filter after standing to obtain wet modified rubber Particles, the wet modified rubber particles are naturally dried and sieved to obtain the modified rubber particles, and the modified rubber particles are sealed and stored for future use.

[0042] The modified rubber particles prepared above are used to prepare natural pumice concrete, specifically according to the following steps:

[0043] Step 1, weighing 370 parts of cement, 720 parts of river sand, 570 parts of natural pumice, 160 parts of water, 7.4 part...

Embodiment 3

[0049] A method for modifying rubber particles, specifically implemented according to the following steps:

[0050] Step 1, prepare a modified solution by mixing Span 40 with a mass concentration of 1% and water at 100°C in a mass ratio of 1:10;

[0051] Step 2, immerse the rubber particles with a particle size of 100 mesh into the modified solution prepared in step 1, and stir at a speed of 30r / min for 80min, after stirring, let stand for 5h, and filter after standing, to obtain wet modified rubber Particles, the wet modified rubber particles are naturally dried and sieved to obtain the modified rubber particles, and the modified rubber particles are sealed and stored for future use.

[0052] The modified rubber particles prepared above are used to prepare natural pumice concrete, specifically according to the following steps:

[0053] Step 1, weighing 400 parts of cement, 750 parts of river sand, 600 parts of natural pumice, 180 parts of water, 7.5 parts of water reducing a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com