A punishing speed bump based on dampers and rubber air springs

A technology of rubber air springs and dampers, which can be applied to roads, buildings, road signs, etc., can solve problems such as severe bumps, and achieve the effect of reducing height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

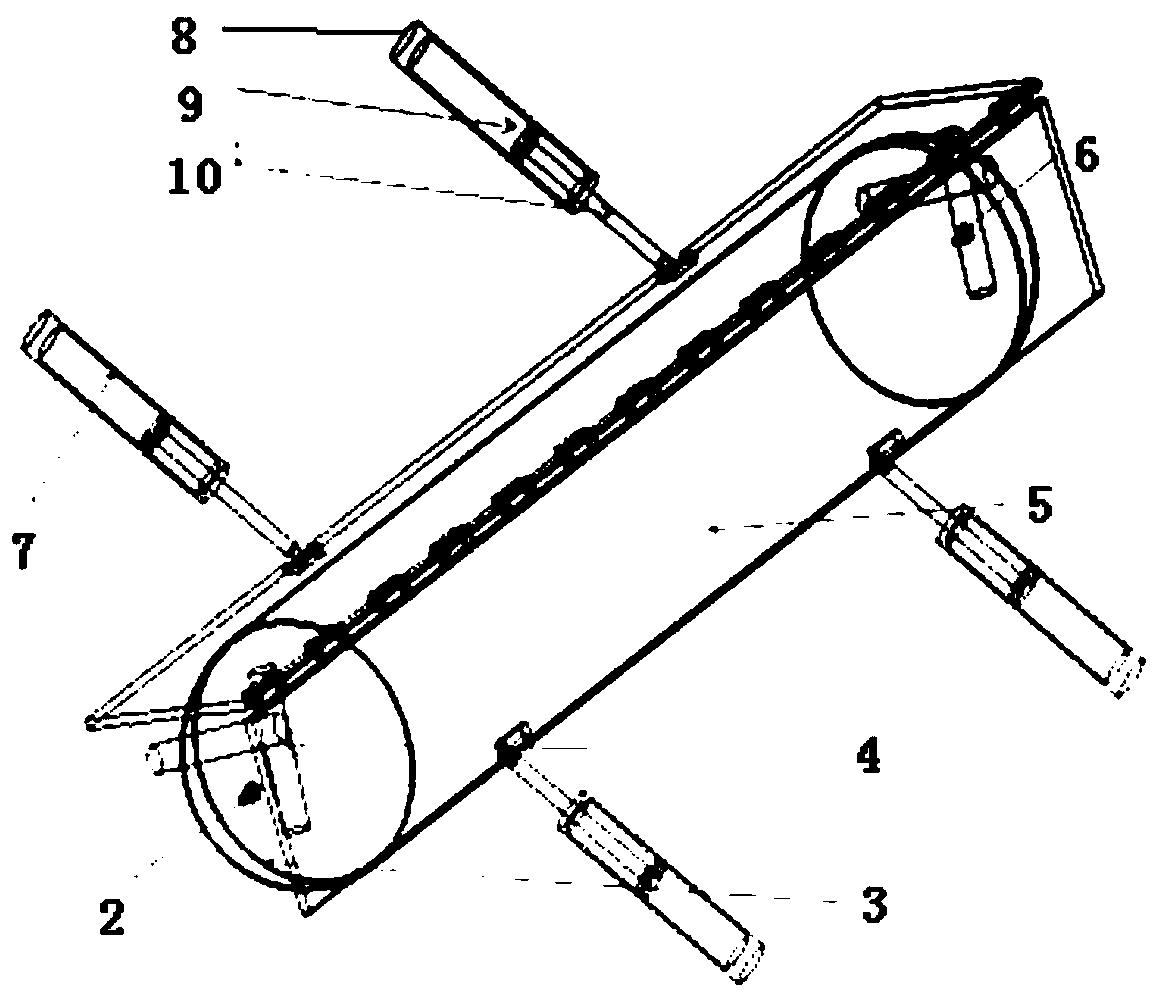

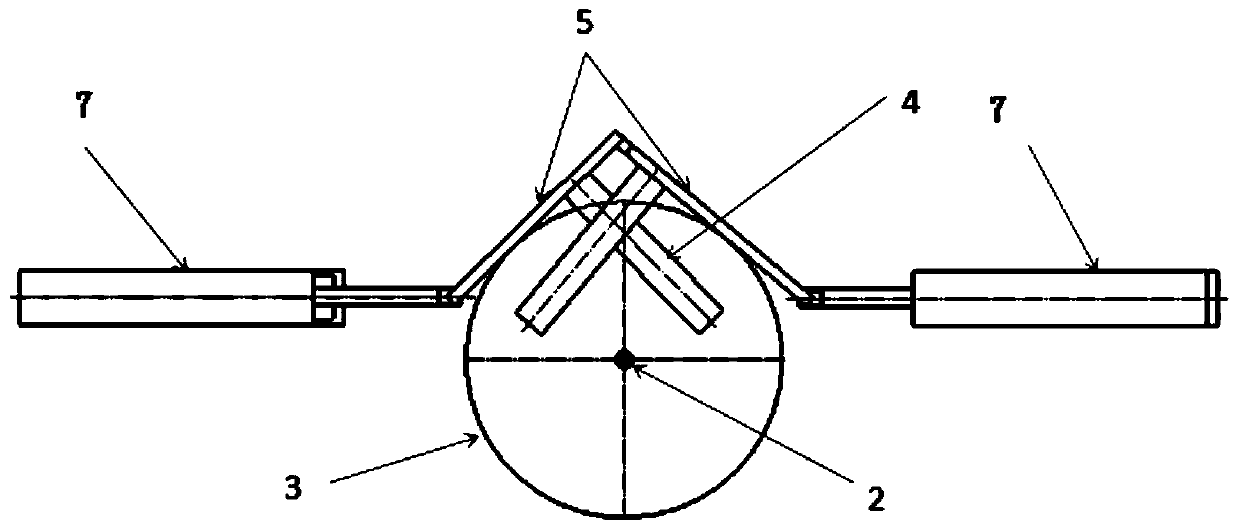

[0015] Embodiment of the present invention: a punishing speed bump based on a damper and a rubber air spring, as shown in the accompanying drawings, includes two speed bumps 5, and the two speed bumps 5 are hinged to form an inverted "cross section" V" structure, rubber air spring 3 is set in the V-shaped space of two speed brakes 5, an air inlet check valve 2 is set at one end of the rubber air spring 3, and an air outlet check valve 6 is set at the other end.

[0016] Wherein the caliber of the air inlet check valve 2 is smaller than the caliber of the air outlet check valve 6, the damper group 7 is arranged symmetrically at the bottom of the two speed brakes 5 and the damper group 7 is hinged to the bottom of the speed brake 5 connected, the damper group 7 is fixed on the ground and kept flat with the ground, the damper includes a cylinder 8, a piston 9 is placed in the cylinder 8, a piston rod 10 is arranged on one side of the piston 9 and the piston rod 10 is hinged on On...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com