Jumping type air tightness test construction method for continuous annealing furnace

A continuous annealing furnace and construction method technology, applied in fluid tightness testing, machine/structural component testing, furnaces, etc., can solve the impact of the installation period of the fast cooling section, the difficulty of construction and installation, and the complex construction process of the fast cooling section, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is further illustrated below by specific examples.

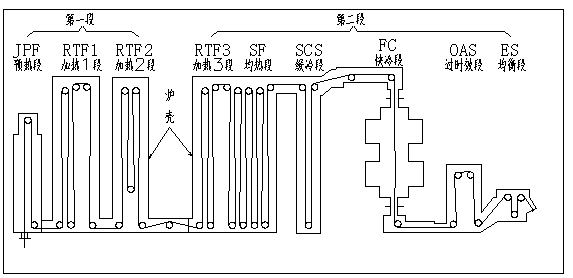

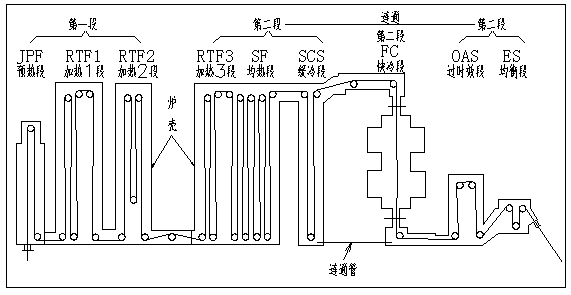

[0023] Such as figure 1 Shown, a kind of continuous annealing furnace jump type air tightness test construction method, including

[0024] Step 1. Divide the entire heating furnace into two furnace sections: the first furnace section includes the preheating section JPF, the first heating section RTF1, and the second heating section RTF2; the second furnace section includes the third heating section RTF3, the soaking section SF, slow cooling section SCS, fast cooling forging FC, overaging section OAS and equalization section ES;

[0025] Step 2, performing an air tightness test on the first furnace section;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com