Construction method of pre-embedded iron for special-shaped branches of trenches

A construction method and pre-embedded iron technology, which is applied in industrial buildings and other fields, can solve problems such as complex styles of maintenance trench branches, increased construction difficulty, and easy deformation of pre-embedded iron parts, so as to reduce the use of wood and related construction materials , Reduce the area of construction land, reduce the effect of carpentry workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

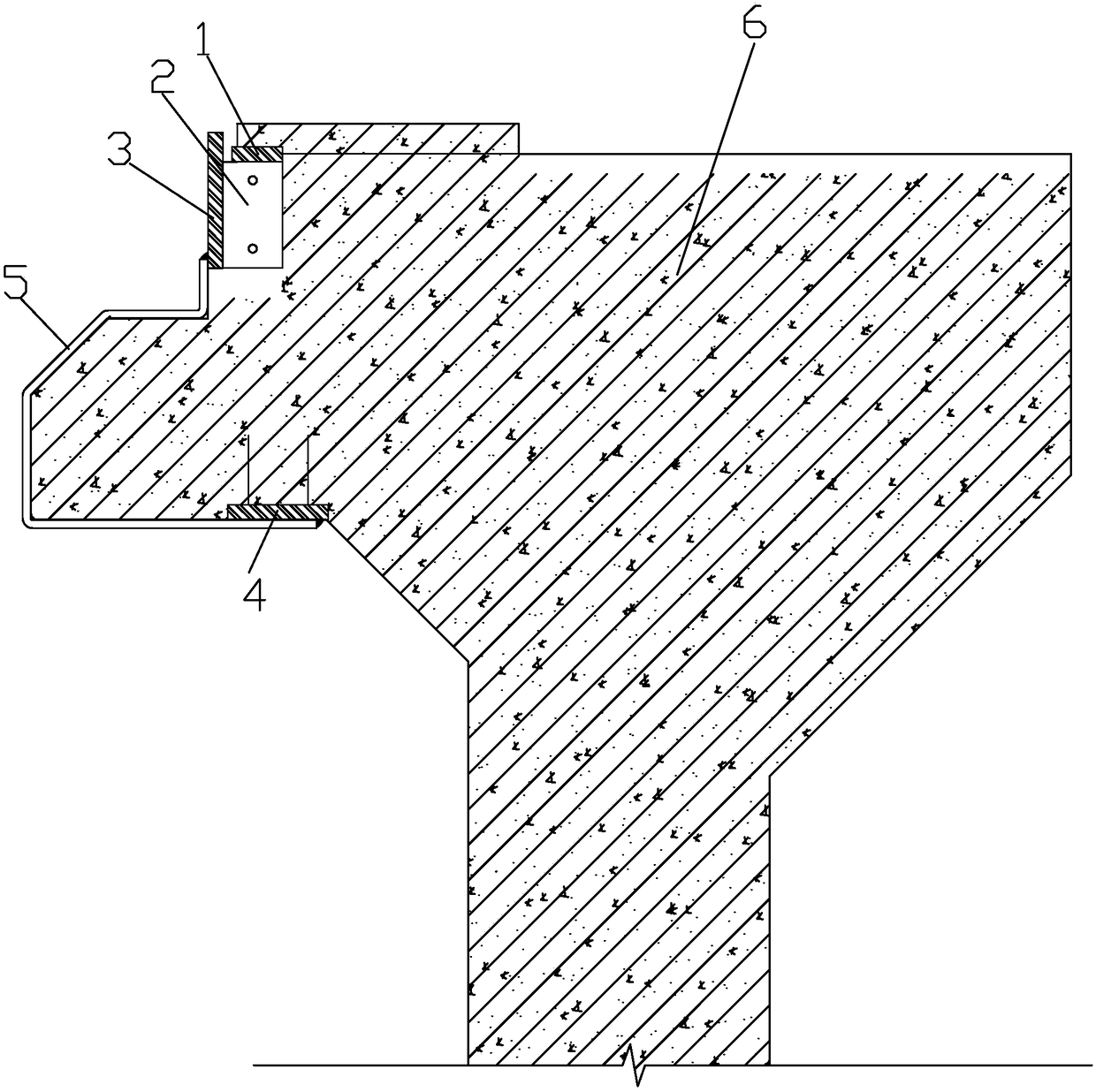

[0024] See figure 2 , The construction method of the embedded iron construction method of the special-shaped branch of the trench in this embodiment will be described by taking the special-shaped branch determined by the trench foundation building 6 of the automobile maintenance trench as an example.

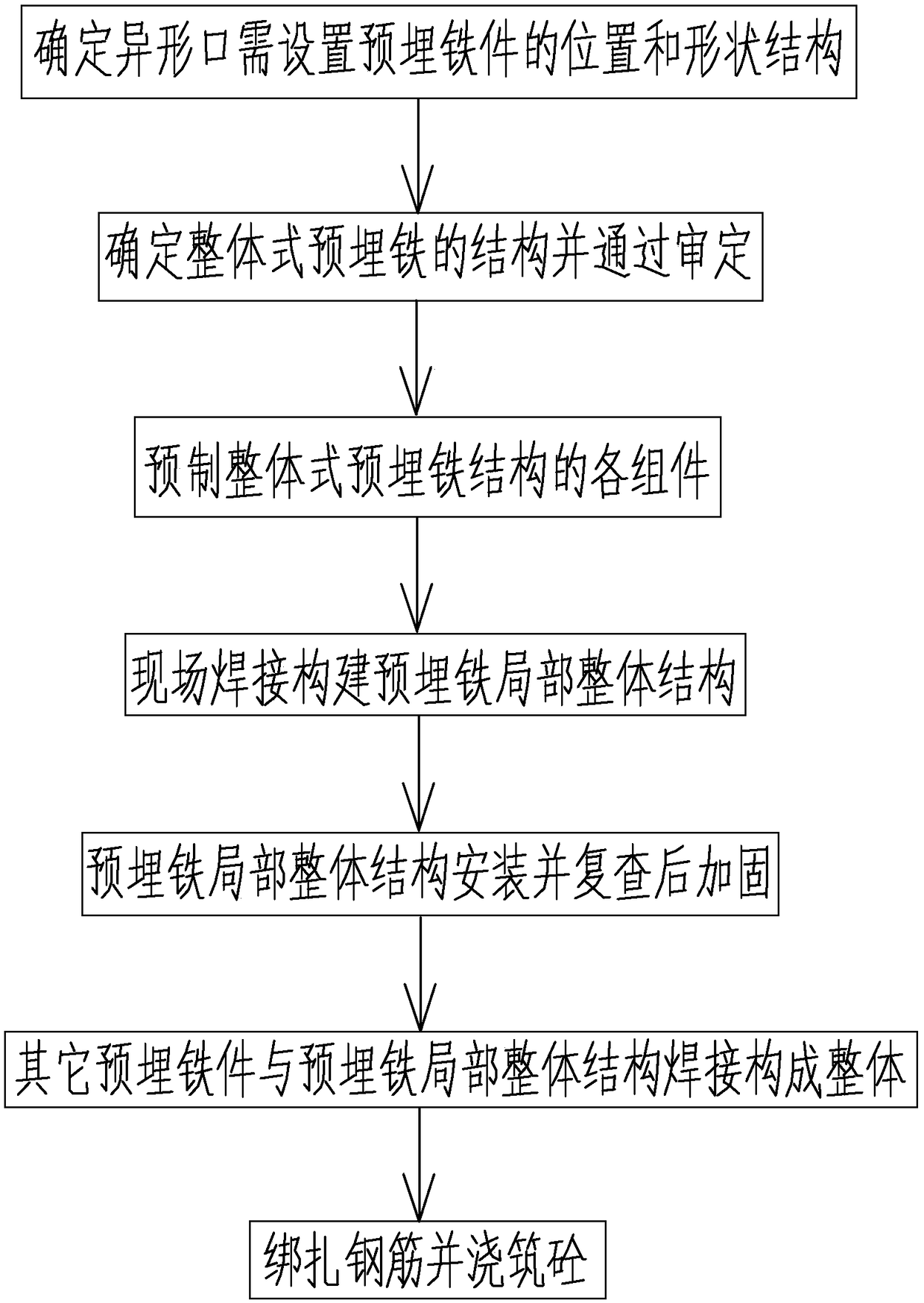

[0025] see image 3 , the construction method of pre-embedded iron in trench special-shaped branch of the present embodiment mainly includes the following steps:

[0026] ①According to the original design requirements provided by the user, determine the position and shape structure of the embedded iron parts that need to be installed at the special-shaped branch of the trench.

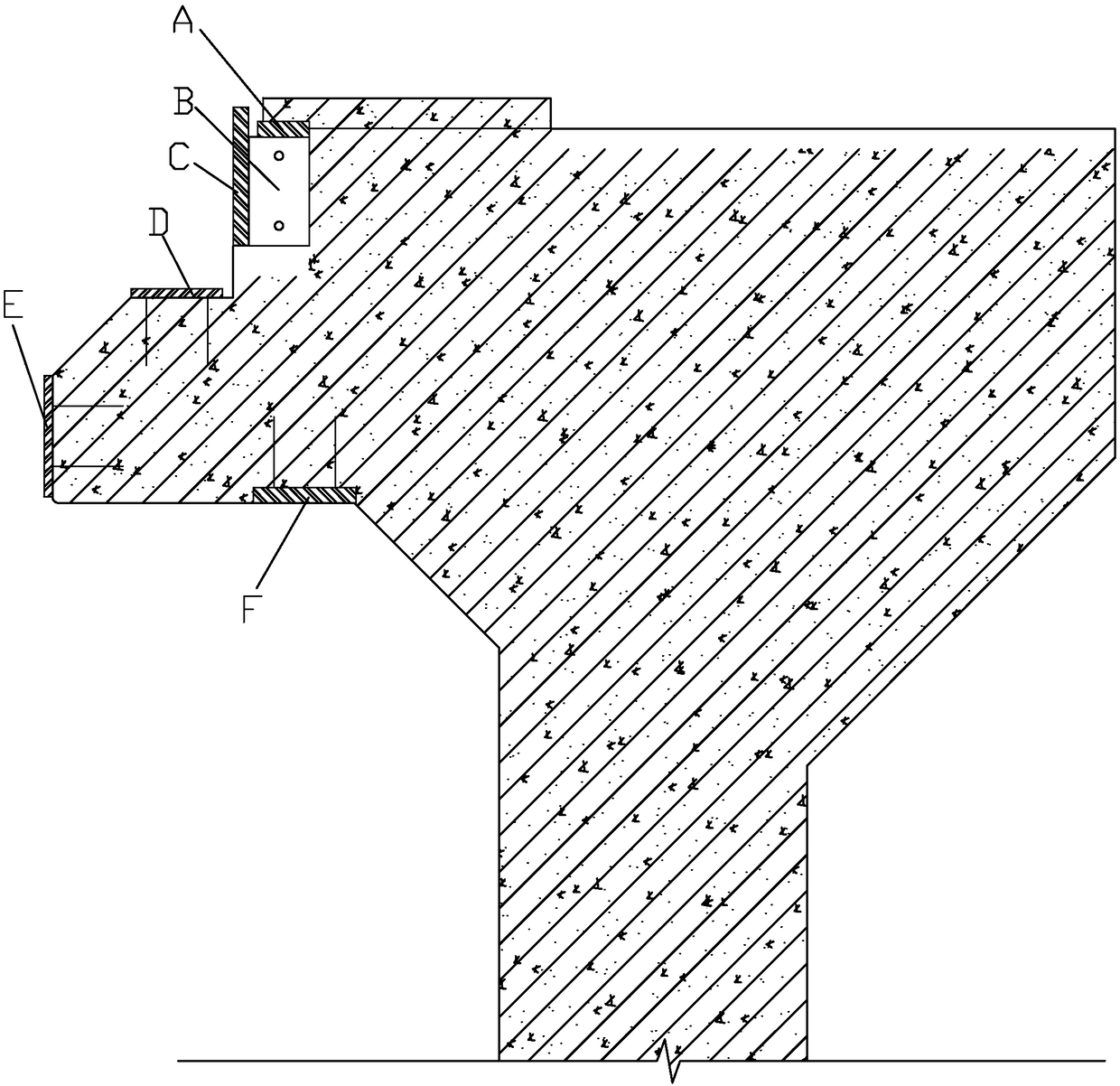

[0027] In this example, if figure 1 As shown, according to the design requirements provided by the user, one piece of embedded iron in total should be installed at A, B, C, D, E, and F respectively. It can be seen from the figure that there are many embedded iron pieces, and the mutual Divided, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com