Electric permanent magnetic chuck device for grasping form boards

An electro-permanent magnetic chuck and formwork technology, which is applied in the direction of electromagnets, electromagnets, permanent magnets, etc. without armatures, can solve the constraints of construction enterprise project progress, construction quality and economic benefits, low operating efficiency, high labor intensity, etc. problems, to achieve the effect of promoting large-scale and scientific development, reducing labor intensity and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

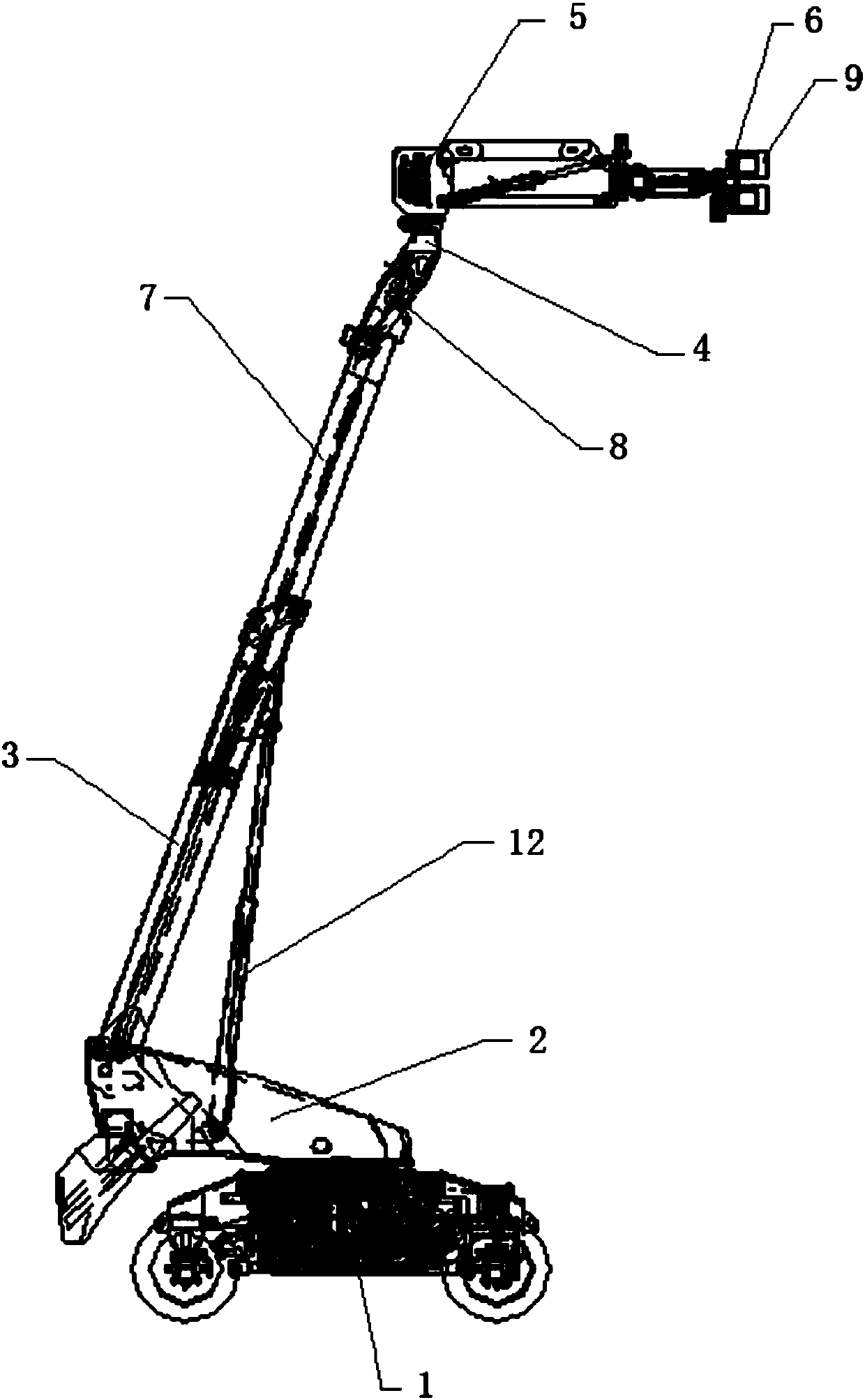

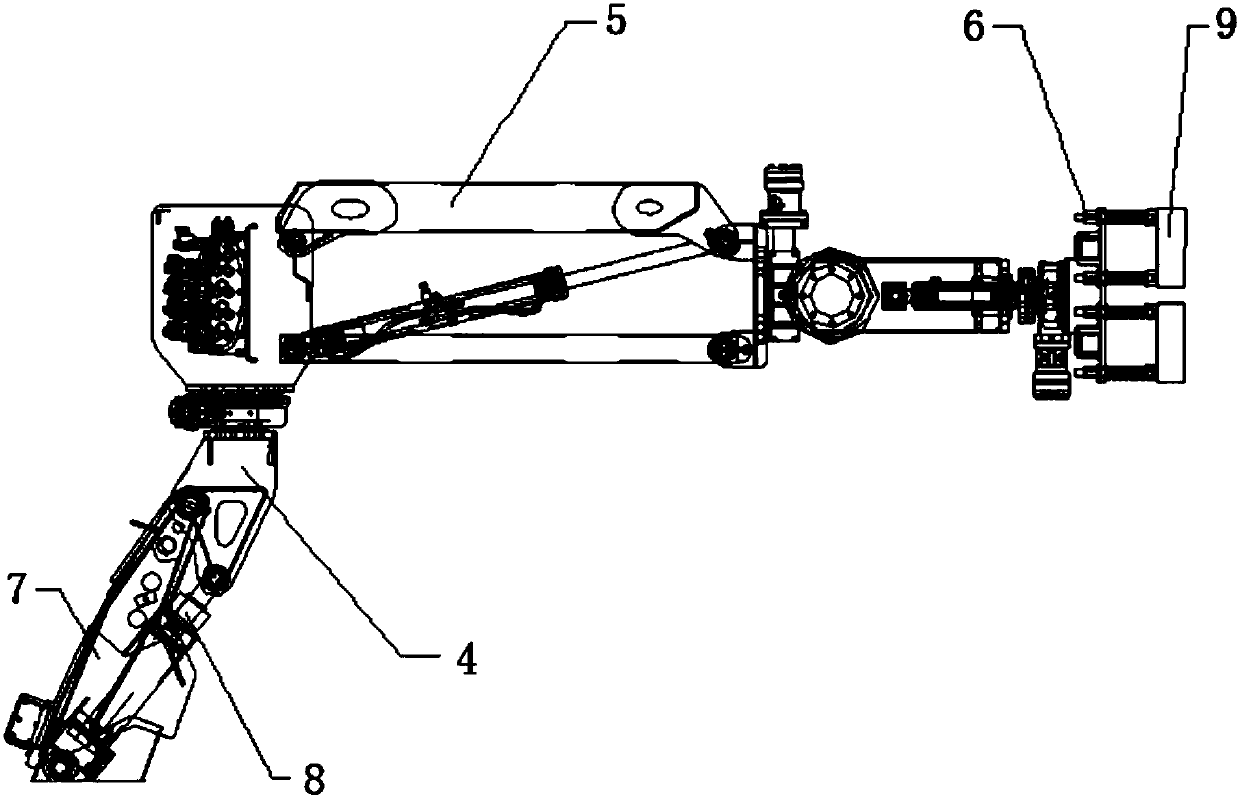

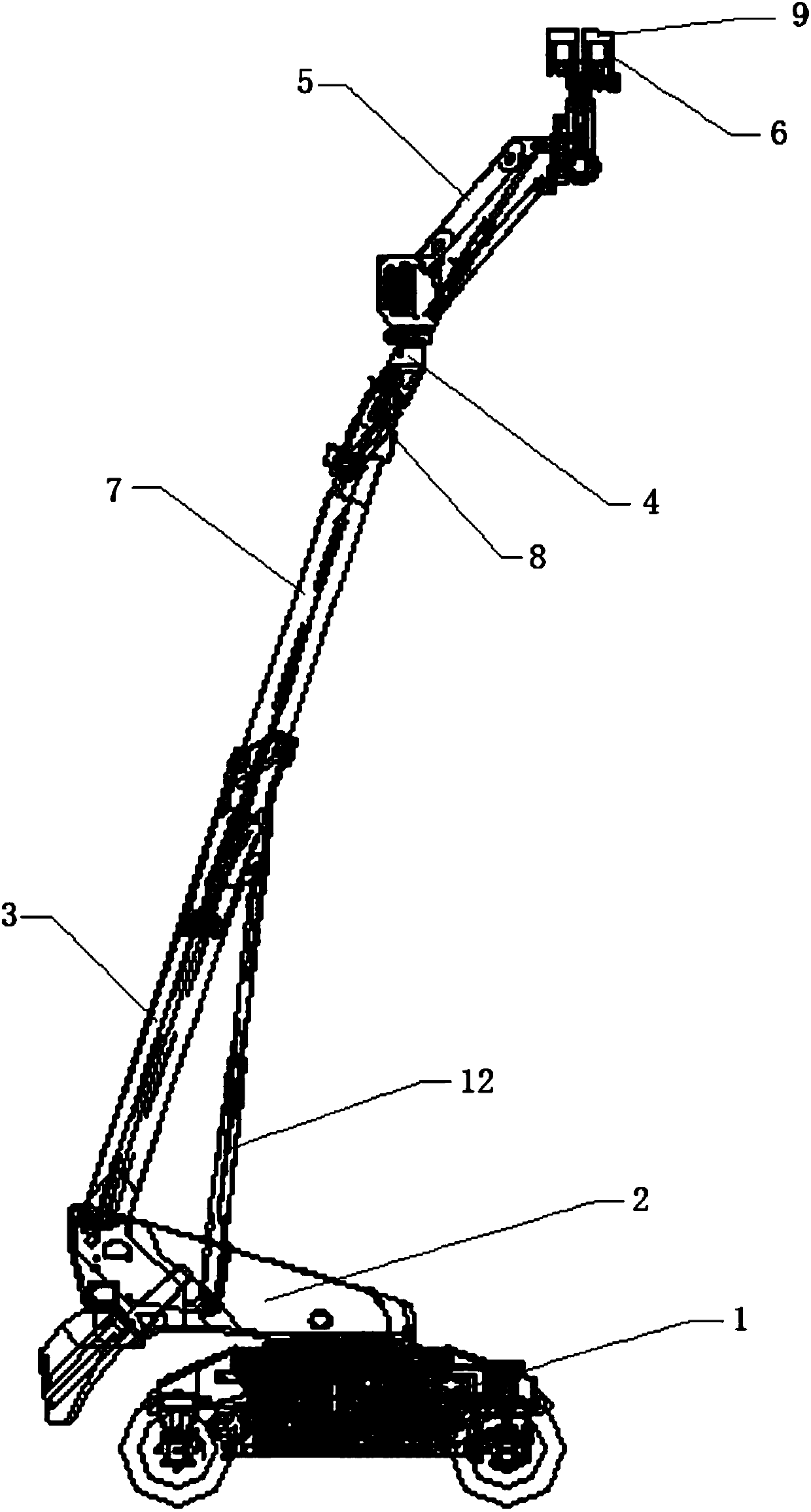

[0021] Such as Figure 1 to Figure 4 As shown, the formwork lifting operation trolley includes a driving chassis 1, a top-loading turntable 2, a telescopic arm frame 3, a leveling support 4 whose upper end surface is a plane, and a multi-axis that can rotate and expand. Manipulator 5 and electric permanent magnetic sucker device 6, described top loading turntable 2 can be arranged on the described running chassis 1 that can rotate horizontally, the bottom of described telescopic boom 3 is hinged with the rear portion of top loading turntable 2, and described telescopic The top of the telescopic arm 7 of the boom 3 is hinged with the left middle part of the leveling support 4, and the telescopic shaft of the leveling oil cylinder 8 provided on the telescopic arm 7 is hinged with the bottom of the leveling support 4. One end of the shaft manipulator 5 is fixedly connected to the upper end surface of the leveling support 4, and the other end of the multi-axis manipulator 5 is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com