Preparation method of array substrate, array substrate and display device

An array substrate and substrate technology, applied in the field of optoelectronic display, can solve the problems of inability to guarantee the uniformity of screen display brightness and high Rs resistance value, and achieve the effects of improving screen display quality, reducing resistance, and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

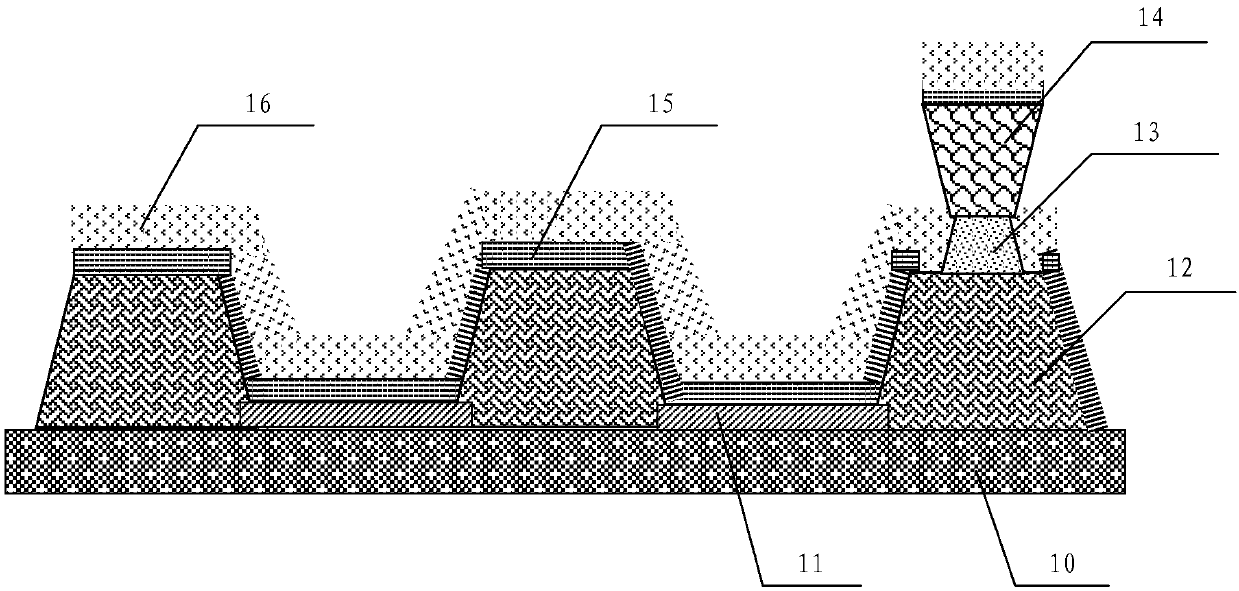

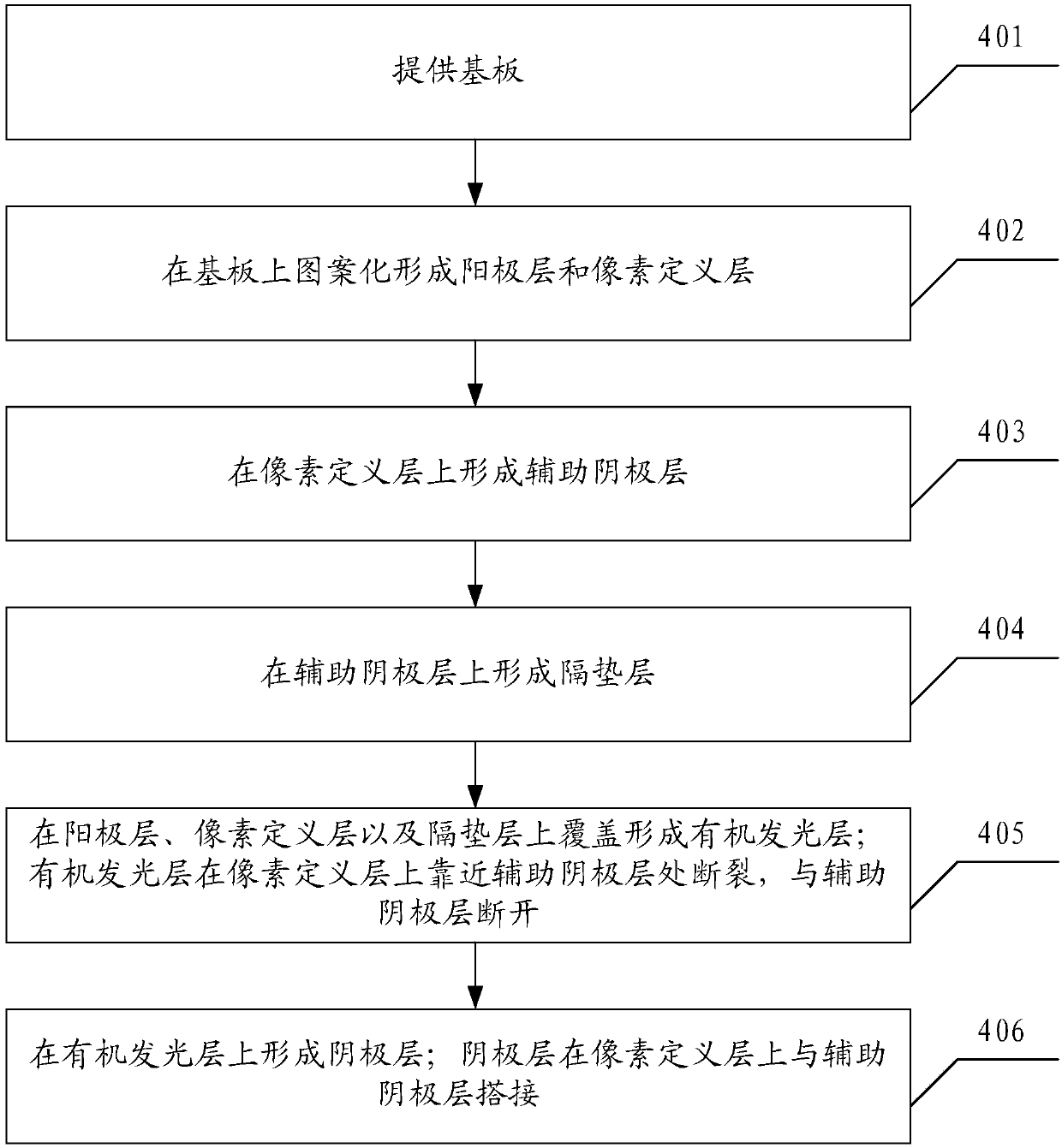

[0046] refer to figure 1 , shows a schematic cross-sectional structure of an array substrate provided in Embodiment 1 of the present application, the array substrate includes a substrate 10 and an anode layer 11 and a pixel definition layer 12 patterned and formed on the substrate 10 .

[0047] An auxiliary cathode layer 13 formed on the pixel definition layer 12 , and a spacer layer 14 formed on the auxiliary cathode layer 13 .

[0048] The organic light emitting layer 15 covering the anode layer 11 , the pixel definition layer 12 and the spacer layer 14 .

[0049] The cathode layer 16 covering the organic light emitting layer 15 .

[0050] Specifically, the substrate 10 may be a BP substrate with a thin film transistor array fabricated, and may also include a planarization layer formed on the BP substrate, wherein the material of the planarization layer may be Resin, PDL, SiNx and other materials.

[0051] The anode layer 11 formed on the substrate 10 by patterning may be ...

Embodiment 2

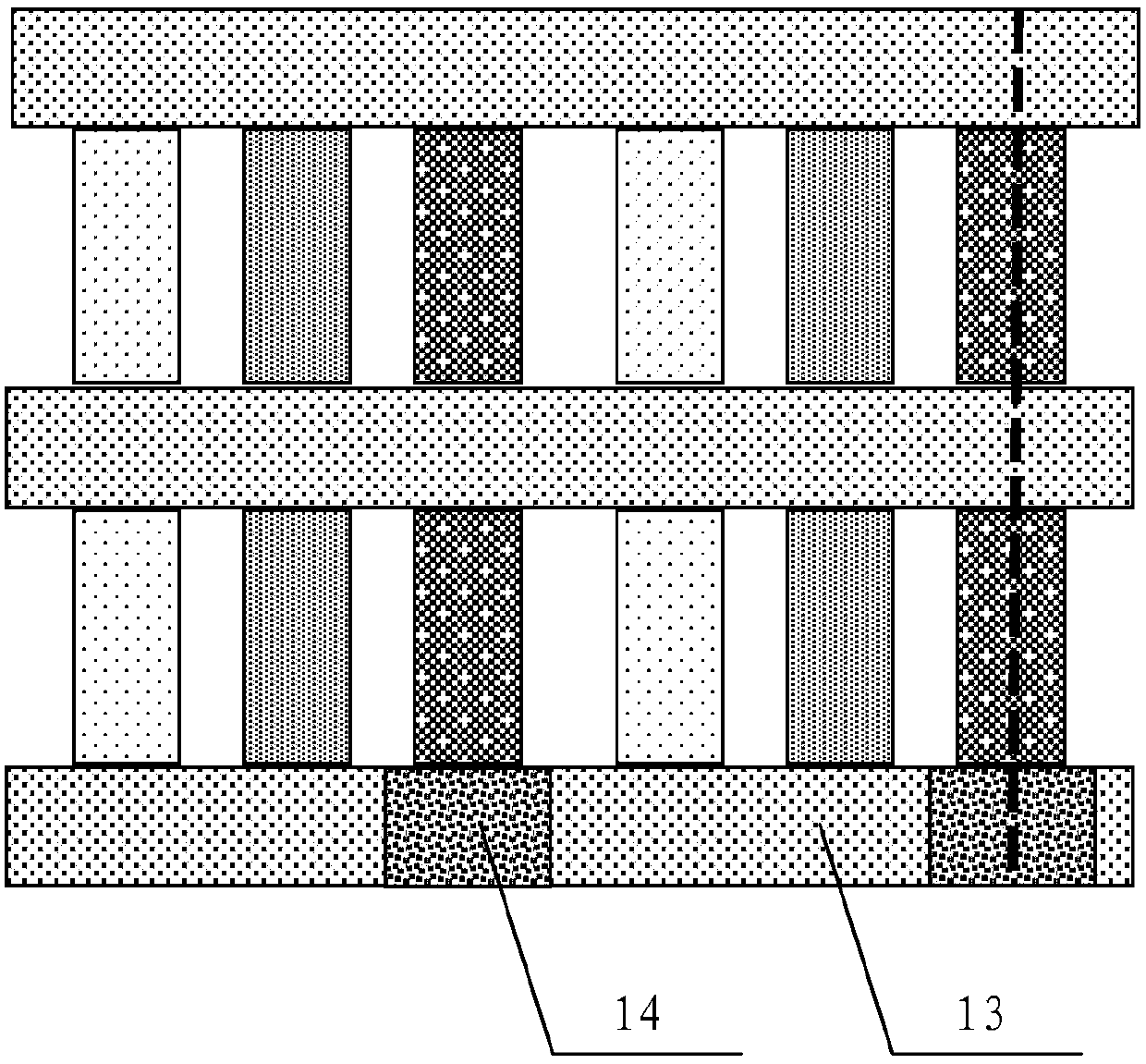

[0061] Embodiment 2 of the present application provides an array substrate, referring to figure 2 The auxiliary cathode layer 13 of the array substrate includes a plurality of auxiliary cathode strips arranged in parallel, and the spacer layer 14 includes a plurality of spacer columns arranged in an array on the auxiliary cathode layer 13. In the directions parallel to and perpendicular to the cathode strips, a spacer column is provided corresponding to every three sub-pixels.

[0062] figure 2 The schematic diagram of the cross-sectional structure corresponding to the position of the dotted line in the middle is as follows: figure 1 As shown, where the dotted line corresponds to the direction of the center line of the pixel unit adjacent to the spacer column, the cross section of the spacer column in this direction is an inverted trapezoid, and the short side of the inverted trapezoid is close to the auxiliary cathode layer 13; and In this direction, the orthographic proj...

Embodiment 3

[0067] Embodiment 3 of the present application provides a display device, including the array substrate described in any one of the above embodiments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com