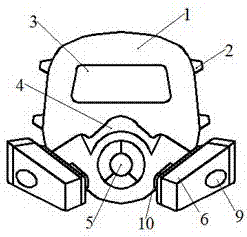

High-efficiency purifying material for high-toxicity gaseous pollutants and device using same

A technology for purifying materials and toxic gaseous states, applied in the field of air purification, can solve the problems of short use time, poor reliability, and poor effect of highly toxic gaseous pollutants, and achieve the effects of convenient disassembly, long use time, and good reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: the processing object of this embodiment: the poisonous gas that certain laboratory experiment process produces, contains hydrogen sulfide and hydrogen cyanide, H 2 The volume concentration of S is 0.5%, and the concentration of HCN is 0.5%.

[0030] The high-efficiency purification material for highly toxic gaseous pollutants in this embodiment consists of a protective layer I, a functional layer, and a protective layer II. A filter plate made of filter cotton and activated carbon fiber; protective layer II is a filter plate made of pretreated dust-proof filter cotton and activated carbon fiber; the pretreatment method is to soak the material in acetone-ethanol mixture for 12 hours , filter to remove the soaking liquid, then boil with distilled water for 3 hours, change the water every 0.5 hours, after suction filtration, dry at 100°C for 20 hours under vacuum, wherein the acetone-ethanol mixture is a mixture of acetone and ethanol in a volume ratio of 1:...

Embodiment 2

[0035] The processing object of this embodiment: toxic gas leaked from a certain factory, containing various harmful gases, mainly H 2 S, SO 2 , CO and AsH 3 , the volume concentration of each toxic gas is higher than 2%.

[0036] The high-efficiency purification material for highly toxic gaseous pollutants in this embodiment consists of a protective layer I, a functional layer, and a protective layer II. A filter plate made of filter cotton, activated carbon filter cotton and glass fiber paper; the protective layer II is a pretreated activated carbon fiber filter plate; the pretreatment method is to soak the material in acetone-ethanol mixture for 20 hours, filter to remove the soaked solution, boil it with distilled water for 2 hours, change the water every 1 hour, and vacuum-dry at 120°C for 15 hours after suction filtration, wherein the acetone-ethanol mixture is prepared by mixing acetone and ethanol at a volume ratio of 1:2;

[0037] The functional layer is composed o...

Embodiment 3

[0041] This example is an extended application of the canister in the material of the present invention, and the processing object is: sulfur-containing industrial flue gas (sulfur content is about 3%) produced by a certain enterprise, containing hydrogen sulfide and sulfur dioxide, and the concentration is relatively high.

[0042] The high-efficiency purification material for highly toxic gaseous pollutants in this embodiment consists of a protective layer I, a functional layer, and a protective layer II. The functional layer is arranged between the protective layer I and the protective layer II, wherein the protective layer I is made of pretreated blue asbestos , activated carbon fiber, and activated carbon filter cotton; the protective layer II is a filter plate composed of pretreated blue asbestos, activated carbon fiber, and activated carbon filter cotton; the pretreatment method is to use acetone-ethanol mixture Soak the material for 15 hours, filter and remove the soaki...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap