High-efficiency crushing device for medical plastic waste

A crushing device and plastic waste technology, applied in the fields of dust removal, grain processing, chemical instruments and methods, etc., can solve the problems of large vibration, noise, incomplete crushing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

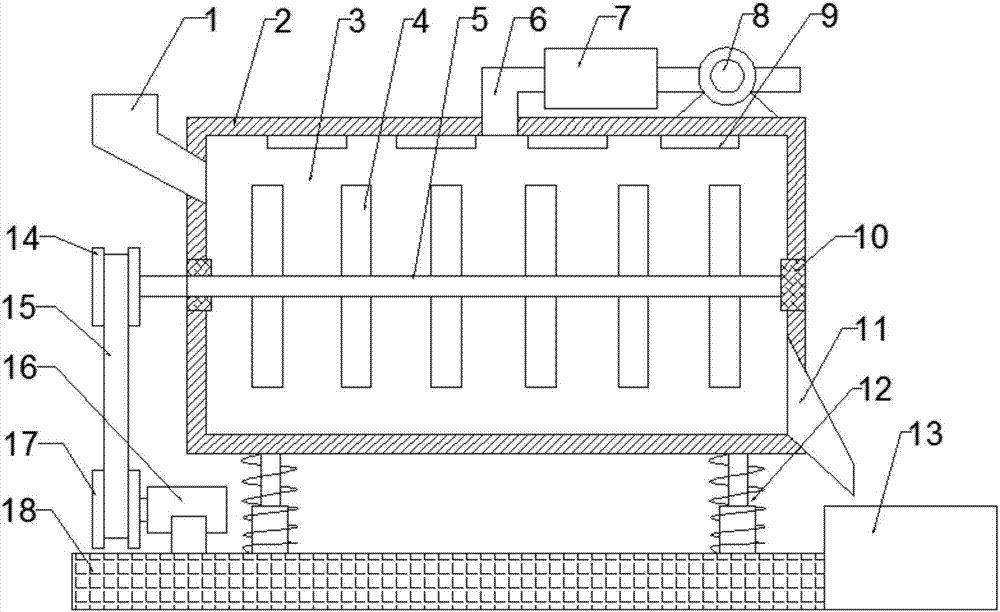

[0015] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

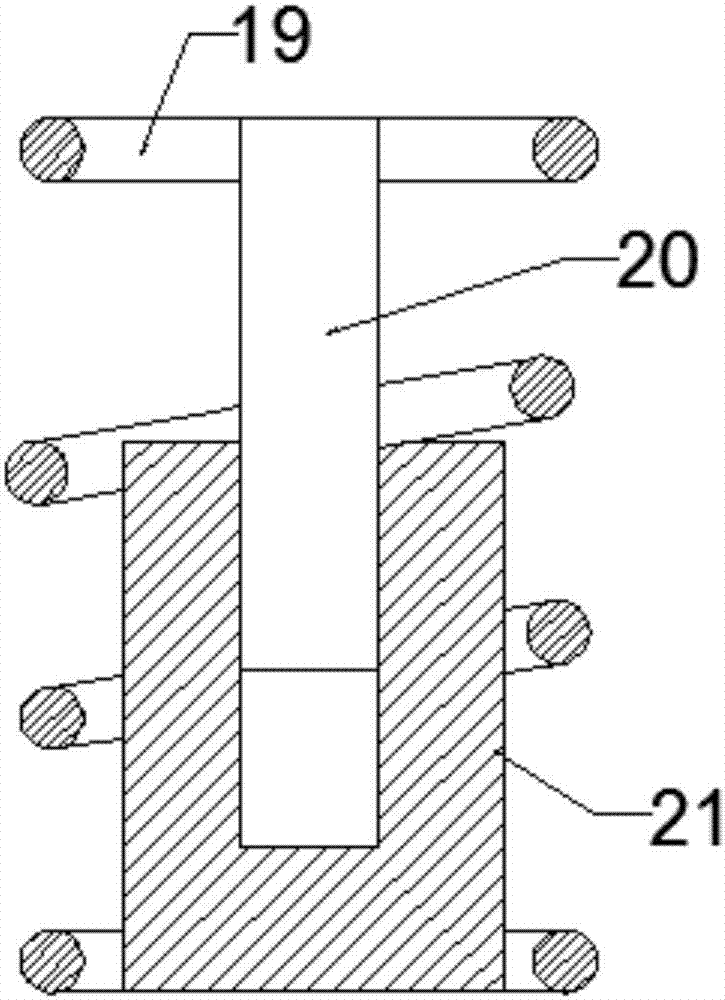

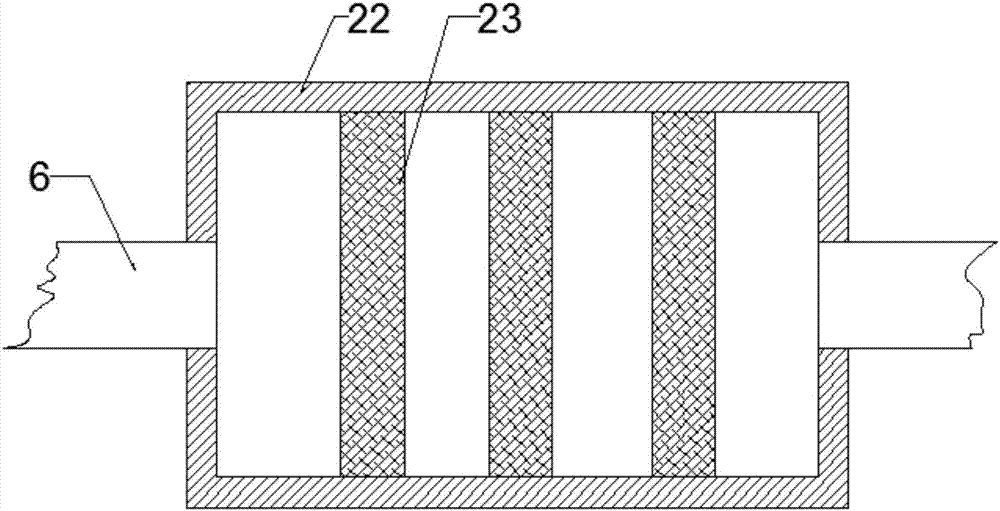

[0016] see figure 1 , this embodiment provides a high-efficiency crushing device for medical plastic waste, including a casing 2; the casing 2 is set as a hollow cylinder, and placed horizontally, with a crushing chamber 3 inside; There is a feed hopper 1, and the feed hopper 1 communicates with the crushing chamber 3; the crushing chamber 3 is provided with a crushing blade 4, a crushing shaft 5 and an ultraviolet sterilizer 9; the crushing shaft 5 is arranged on the center line of the crushing chamber 3 On the upper side, the right side is connected with the right wall of the crushing chamber 3 through the bearing 10, and the left side is connected with the second transmission wheel 14 through the left wall of the crushing chamber 3 through the bearing 10; the second transmission wheel 14 is arranged in the casing 2 Outside the left wall, the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com