Base for prolonging life of pipelines of robot

A technology of robots and industrial robots, applied in the direction of manipulators, manufacturing tools, etc., can solve the problems of pipelines that cannot be separated from each other, easily entangled, damaged, etc., to achieve the effect of providing work efficiency, not easy to entangle, convenient for replacement and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

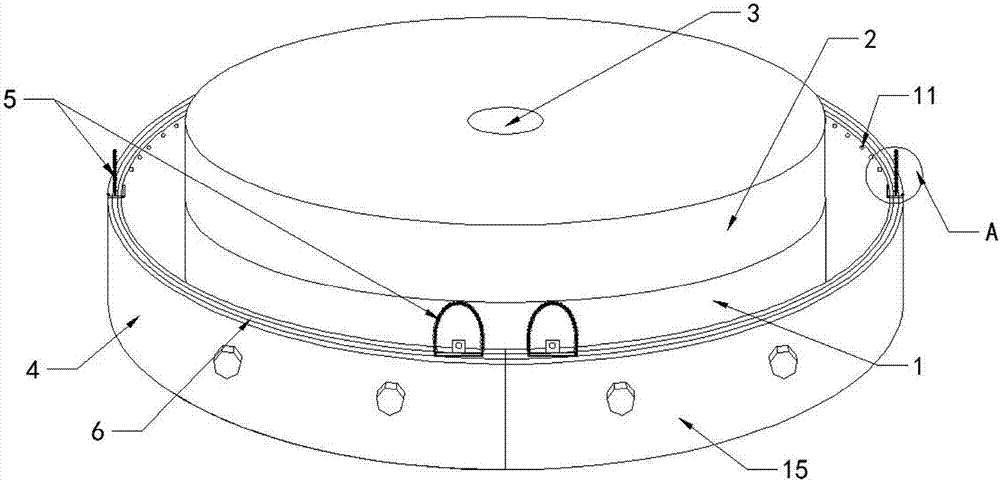

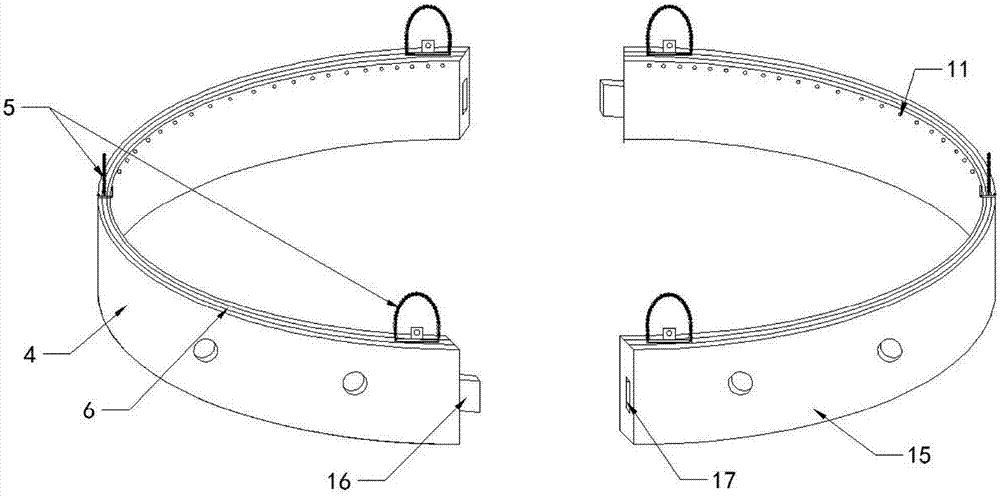

[0032] A base for prolonging the life of a robot pipeline, comprising a lower base 1, an upper base 2 arranged above the lower base 1 connected to an industrial robot, and a bearing 3 connecting the lower base 1 and the upper base 2, the outer ring of the lower base 1 is provided with a protective Plate 4, a plurality of brackets 5 are arranged on the top of the protection plate 4; the protection plate 4 is movably connected with the lower base 1 through bolts;

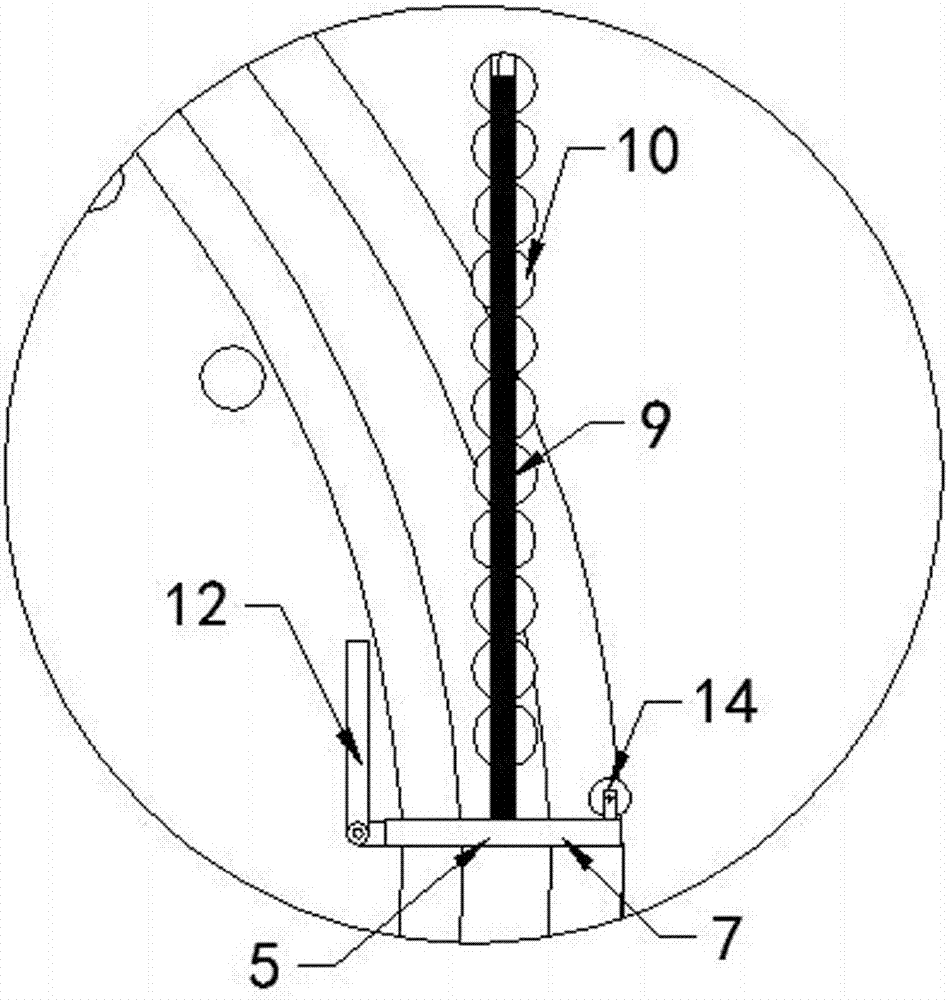

[0033] The top of the protective plate 4 is provided with a chute 6 that matches the protective plate 4, and the bottom of the bracket 5 is inserted into the chute 6 and can slide along the chute 6; the bracket 5 includes a sliding seat 7, and the sliding seat 7 The lower part is provided with a clamping column 8 which is inserted into the chute 6, and a circular ring 9 which is adapted to the radian of the chute 6 is vertically provided above the sliding seat 7, and a plurality of balls 10 are set on the circular ring...

Embodiment 2

[0036] This embodiment is further optimized based on Embodiment 1. The sliding seat 7 is provided with a roller 14 near the outer wall of the protective plate 4. The roller 14 protrudes from the outer wall of the protective plate 4. The roller 14 can reduce the gap between the bracket 5 and the peripheral pipeline. frictional force to avoid abrasion of peripheral pipelines; because the upper corners of the protective plate 4 are sharper than the plane, the peripheral pipelines will be damaged if they contact the upper corners of the protective plate 4 for a long time, and the roller 14 protrudes from the outer wall of the protective plate 4 to avoid the peripheral pipelines and the protective plate 4. The upper edges and corners are in contact, and the friction with the peripheral pipeline is rolling friction, which greatly improves the service life of the peripheral pipeline.

Embodiment 3

[0038] This embodiment is further optimized based on Embodiment 1. The protective plate 4 includes two semicircular baffles 15, the two ends of the baffles 15 are respectively provided with joints 16 and interfaces 17, and the interface 17 between the two baffles 15 It is connected with the joint 16, and the two baffles 15 are connected. When loading and unloading the protective plate 4, the robot base does not need to be moved, and the protective plate 4 can be directly loaded and unloaded, which is more convenient to use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com