Casing processing device for axial flow air compressor based on synthetic jet

A technology of axial flow compressor and synthetic jet, which is applied to parts of pumping devices for elastic fluids, machines/engines, mechanical equipment, etc., can solve the problem of limited application range, synthetic jet technology has not been practically applied, and increased equipment Negative complexity and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] This embodiment is applied on the isolated rotor of a certain axial flow compressor laboratory, and the design parameters of the rotor are as follows:

[0022] Table 1 Design parameters of the rotor

[0023]

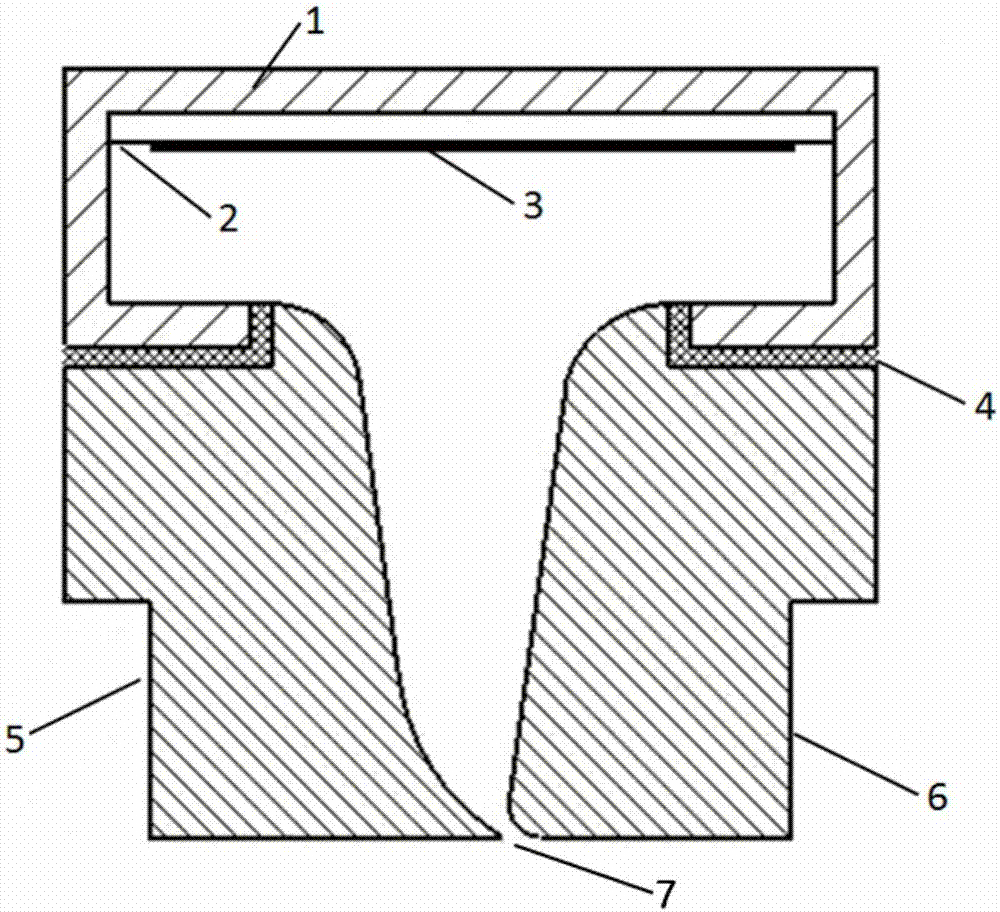

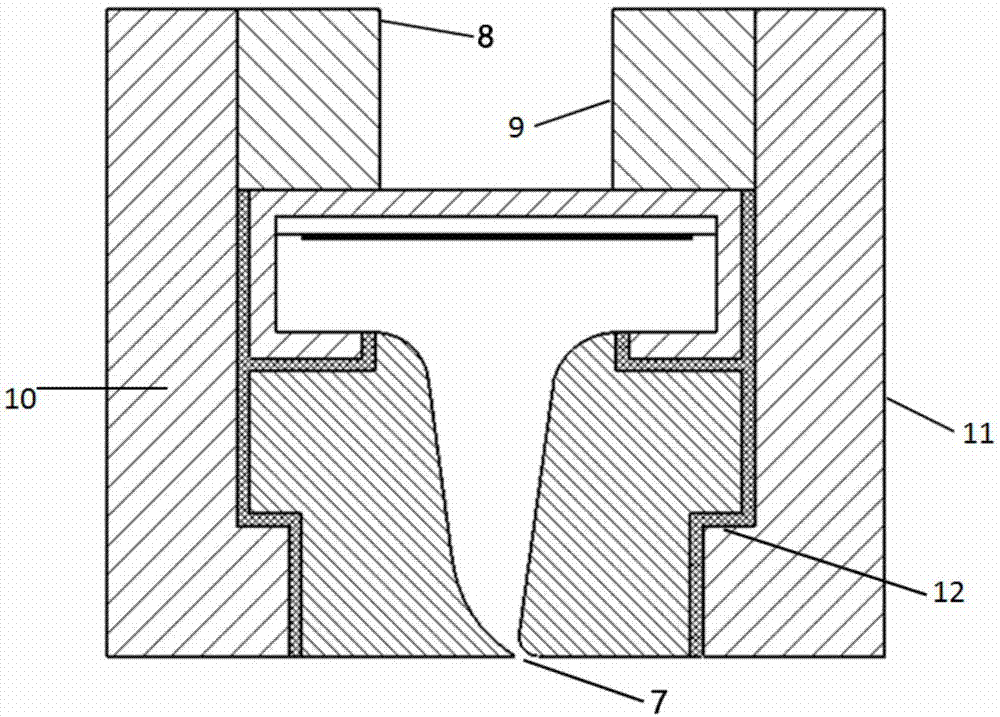

[0024] figure 1 The sectional structure of the synthetic jet generator shown is obtained by rotating 6° along the rotation axis of the impeller. The synthetic jet generator consists of a cavity 1 , a metal film 2 , a piezoelectric layer 3 , a first solid block 5 , and a second solid block 6 . Wherein, the metal film 2 is fixed on the upper part of the cavity 1 , and the metal film 2 is used to install and support the piezoelectric layer 3 . The piezoelectric layer 3 is fixed under the metal film 2 and is opposite to the jet hole 7 formed by the first solid block 5 and the second solid block 6 located at the lower part of the cavity 1, and the first solid block 5 and the second solid block 6 are clamped on the At the groove shoulder 12 on the inner wall of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Axial dimension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com