Shape memory alloy interference fit thread connection assembly

A memory alloy, interference fit technology, applied in the direction of connecting components, threaded fasteners, screws, etc., can solve the problems of small interference, bulge, uneven interference, etc., to achieve large material recovery force and reliable anti-loosening effect. , to avoid the effect of uneven amount of interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below with reference to the accompanying drawings. Obviously, the accompanying drawings in the following description are only some implementation cases recorded in the present invention. For those of ordinary skill in the art, other Attached.

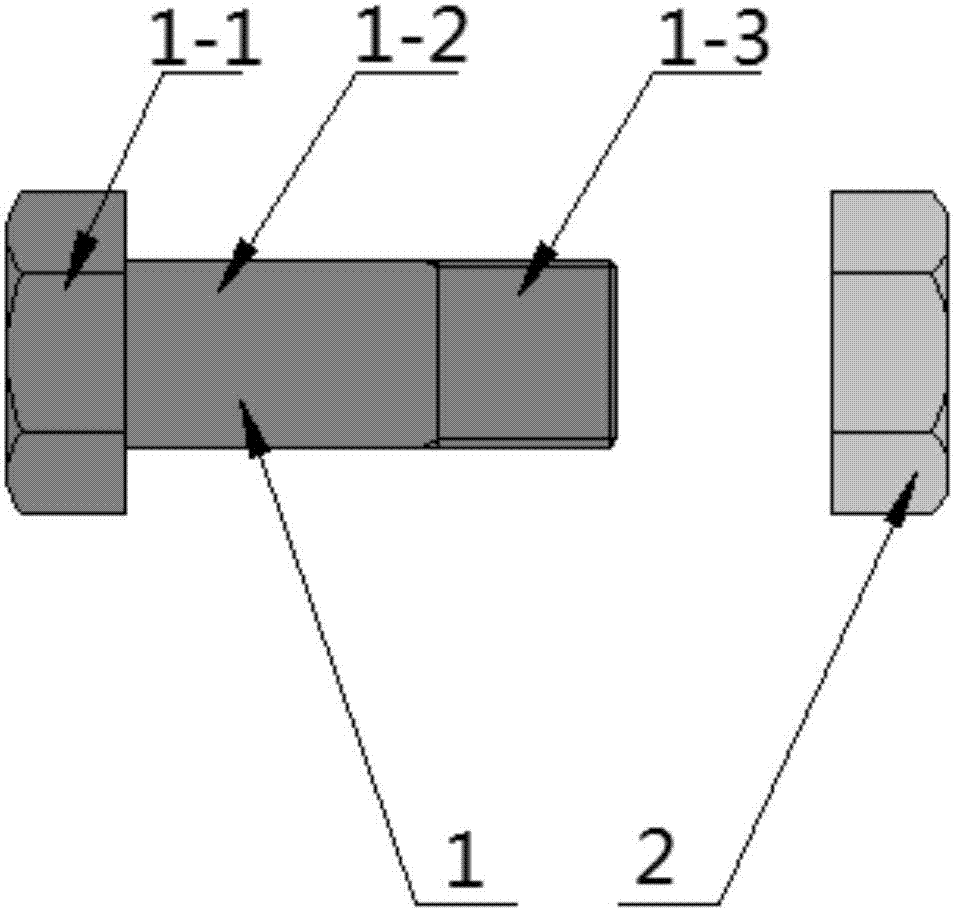

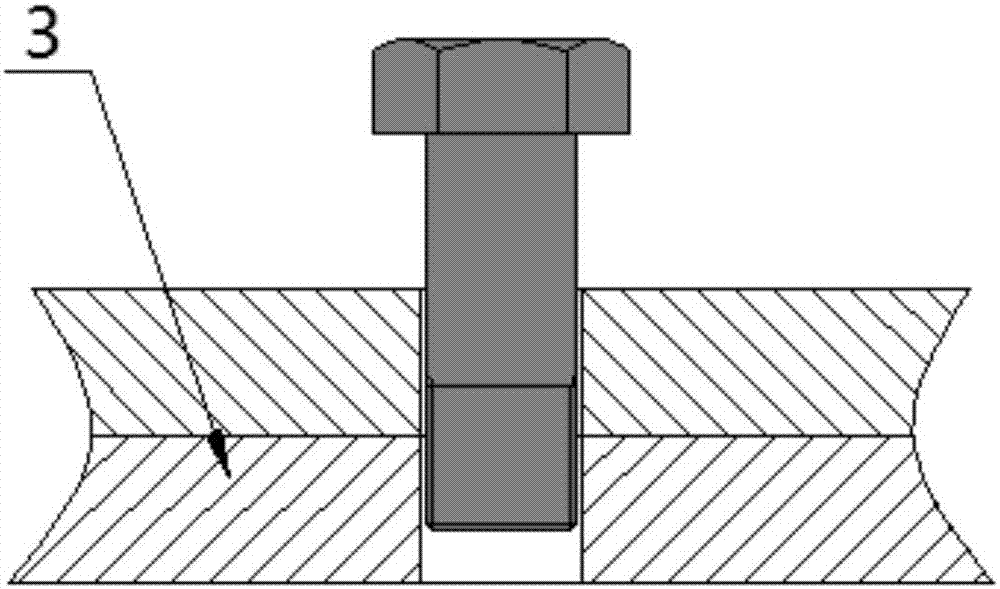

[0020] like figure 1 and figure 2 As shown, a shape memory alloy interference fit screwing assembly includes: a shape memory alloy bolt 1 and a shape memory alloy nut 2 threadedly matched with the shape memory alloy bolt;

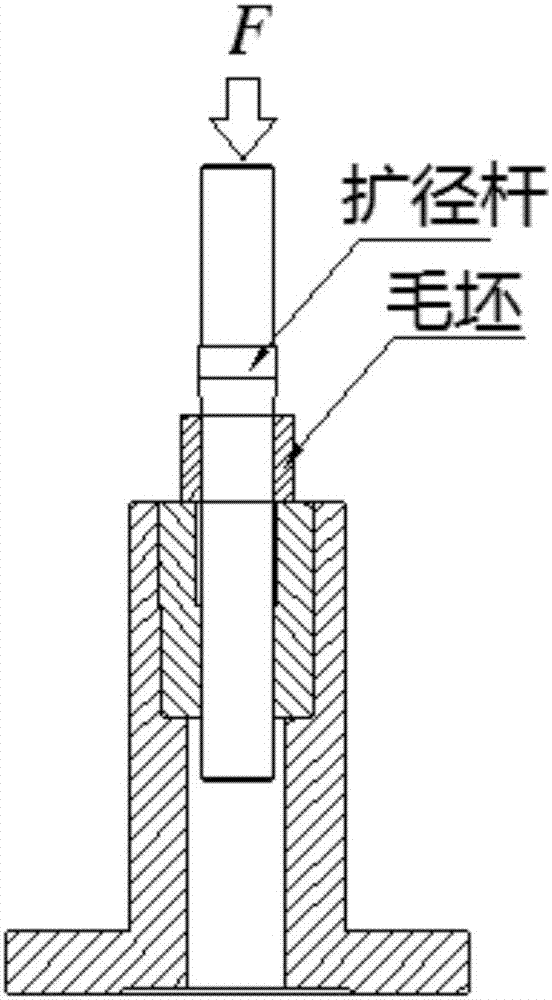

[0021] The shape memory alloy bolt 1 includes a bolt head 1-1 in contact with the connected part; a smooth rod part 1-2 in interference fit with the connected smooth hole (referring to the connection through hole preset by the connected part); and a nut thread Threaded parts 1-3 of the connection. The structure of the shape memory alloy nut 2 includes an inner screw hole connected with the threaded portion of the shape memory alloy bolt and an outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com