A Double-Stator Magnetic Concentration-Reluctance Hybrid Rotor Motor

A hybrid rotor and double stator technology, applied in the direction of magnetic circuit rotating parts, electromechanical devices, electrical components, etc., can solve the problems of independent design, limited torque density, and low utilization rate, so as to improve utilization rate and reduce The amount of permanent magnets and the effect of increasing torque density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

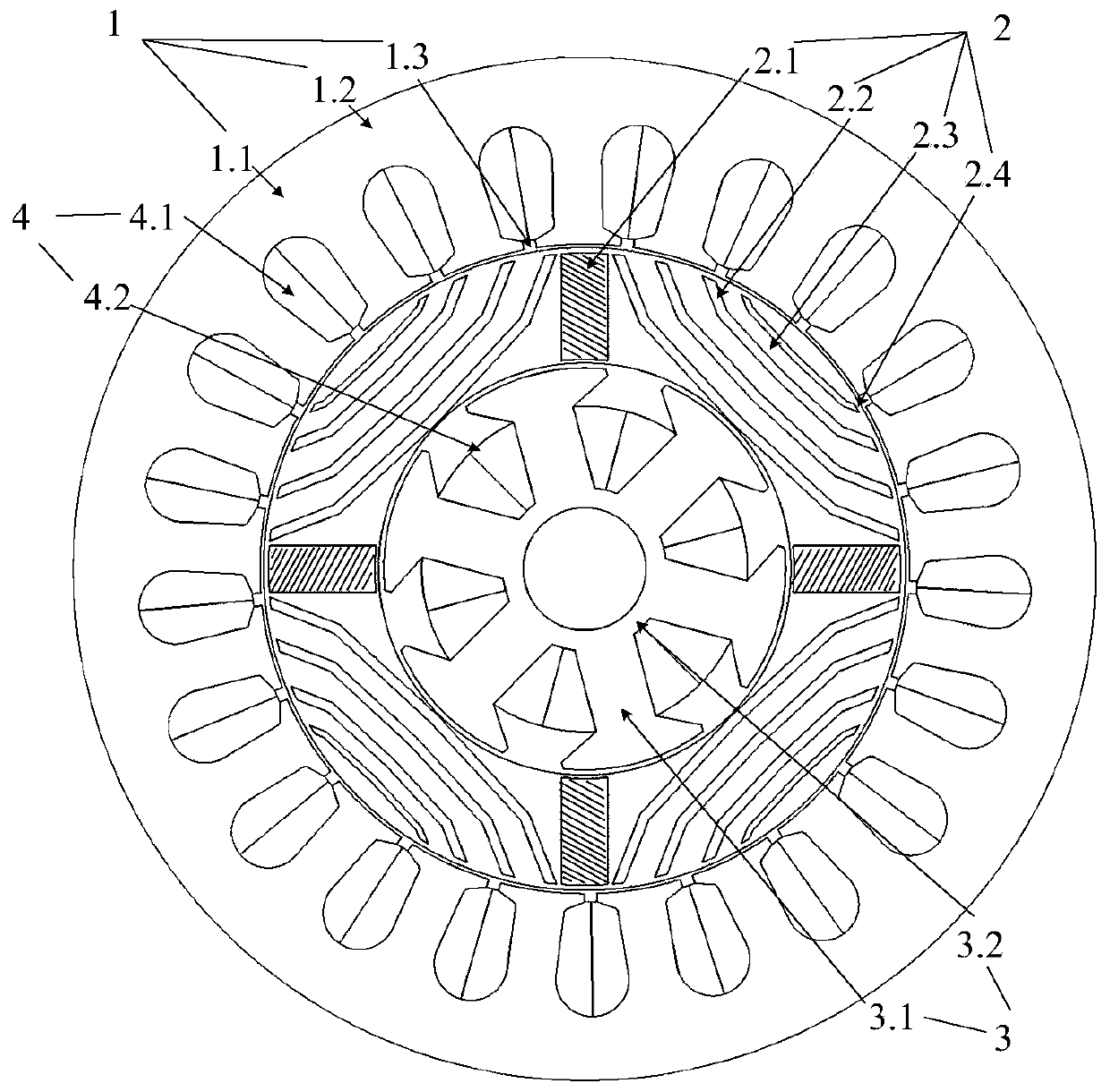

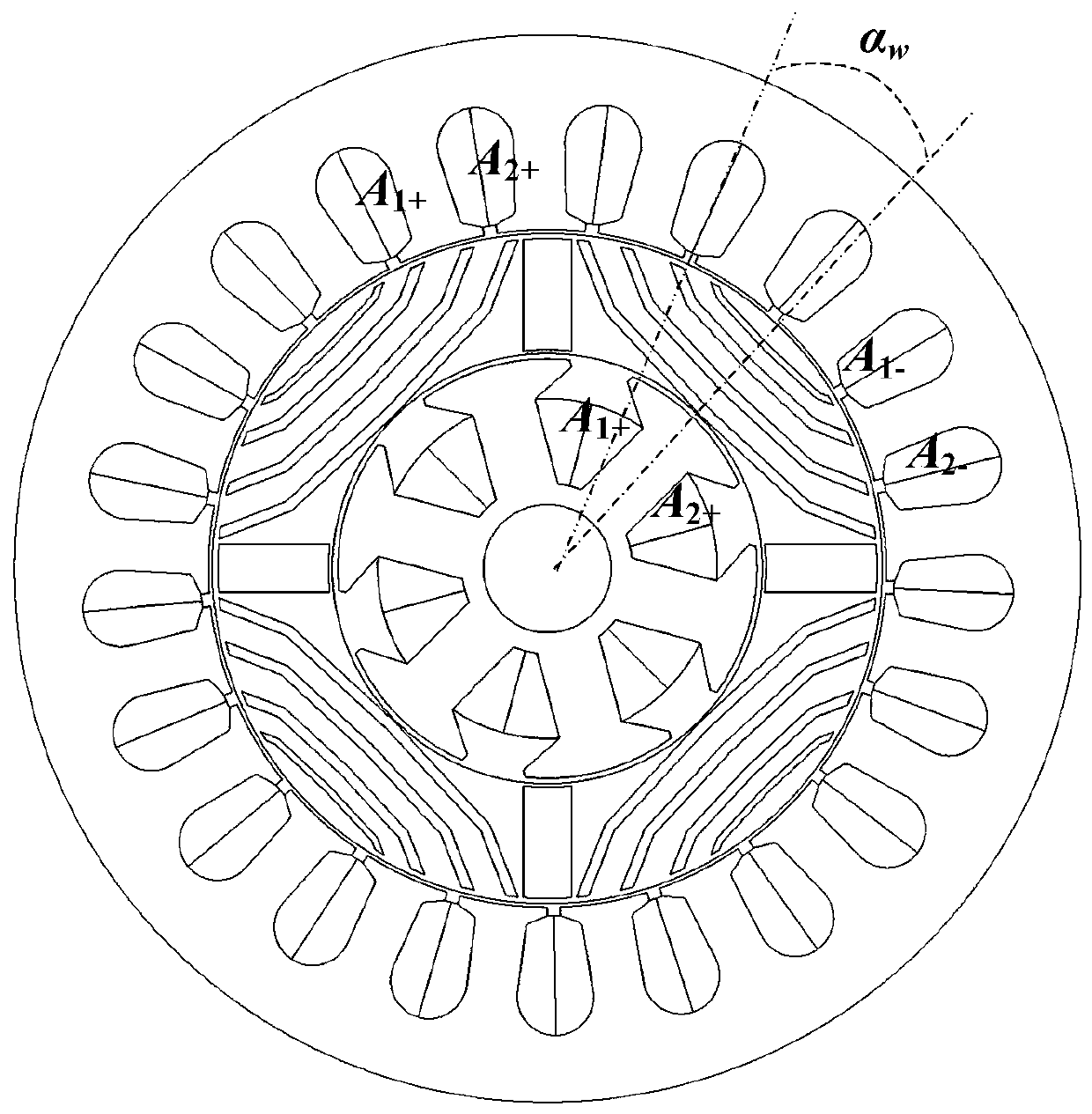

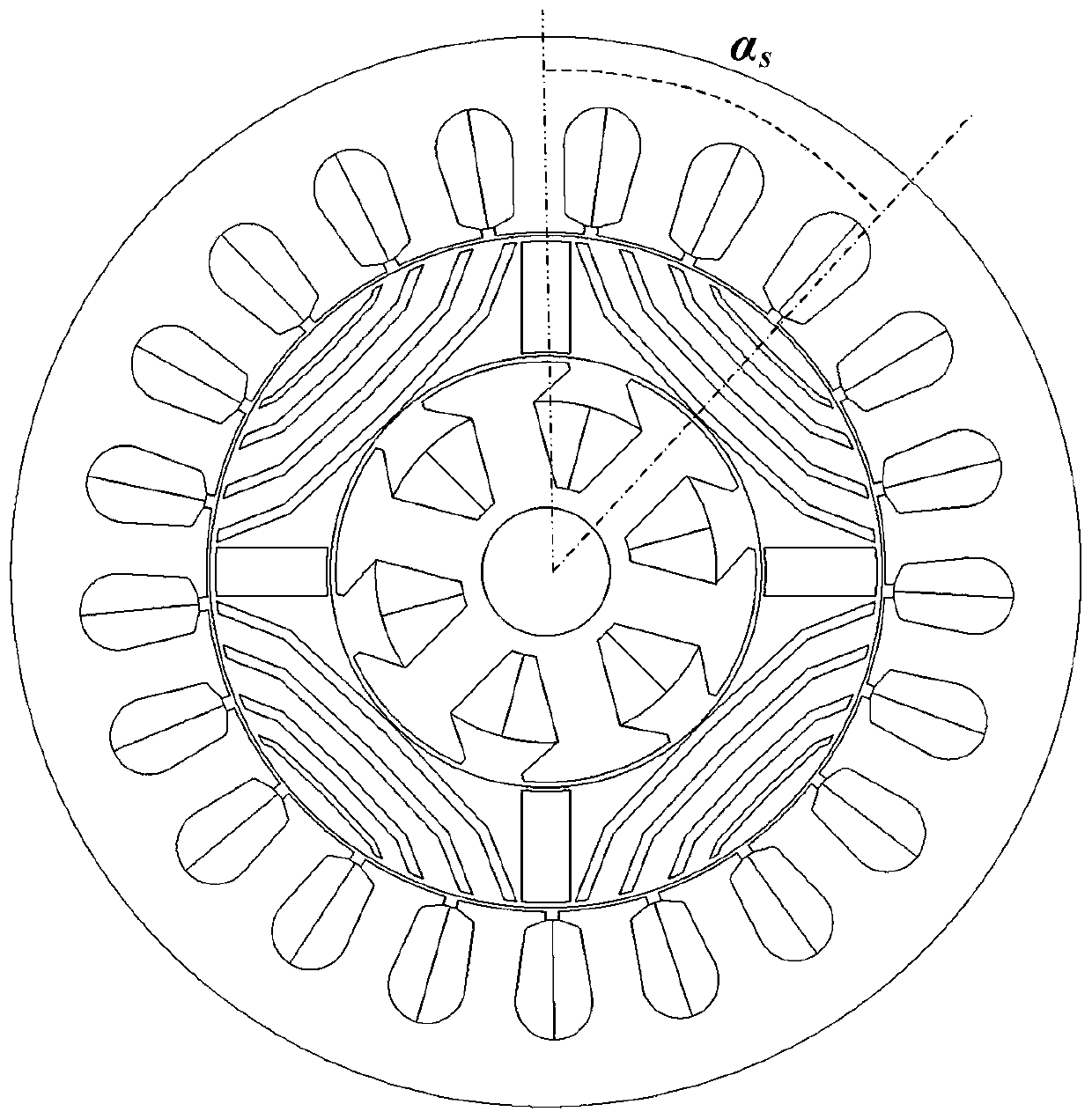

[0031] The dual-stator magnetism-reluctance hybrid rotor motor of this embodiment is similar in structure to a traditional dual-stator motor, the two stators are coaxially installed, and the rotor structure is similar to a traditional built-in permanent magnet motor, which is a hollow cup structure, but it is different The reason is: the rotor cleverly designs the magnetism-concentrating permanent magnet and the multi-layer barrier-type reluctance part, and realizes the separation design of the permanent magnet torque and the reluctance torque of the motor through the staggering of the center line of the inner and outer stator A-phase windings. It solves the problem that the permanent magnet and reluctance design of the traditional built-in permanent magnet motor are difficult to balance, so that the permanent magnet torque and reluctance torque components can be designed separately, which improves the design space freedom and permanent magnet utilization, and further improves t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com