A kind of rice milk pudding and preparation method thereof

A technology of milk pudding and rice, which is applied in the field of food processing, can solve the problems of improper cooking and easy retrogradation of rice, and achieve the effects of not being easy to stick into pieces, saving production costs, and keeping the state of rice grains intact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

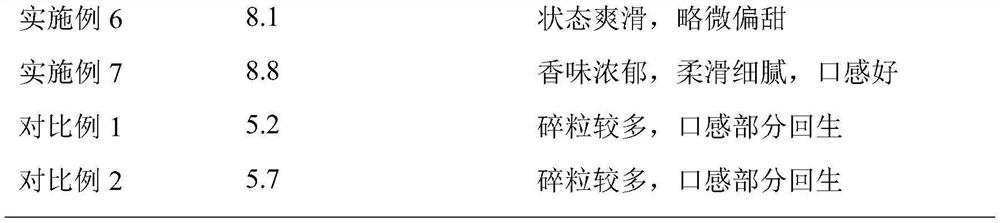

Examples

Embodiment 1

[0043] pre-cooked rice

[0044] Take 20g of fresh rice, wash it twice with 200mL of water, and drain. Take 200-300mL of milk to preheat, then add the drained rice, soak for a period of time, and then put it into a steamer to cook to obtain the pretreated rice. After the pretreatment is completed, drain the rice, observe and compare the morphology of the rice grains prepared under different parameters, and evaluate the softness, waxiness, color and other aspects. Try different soaking temperature, time and cooking time to affect the effect of rice pretreatment, and the results are shown in the table below.

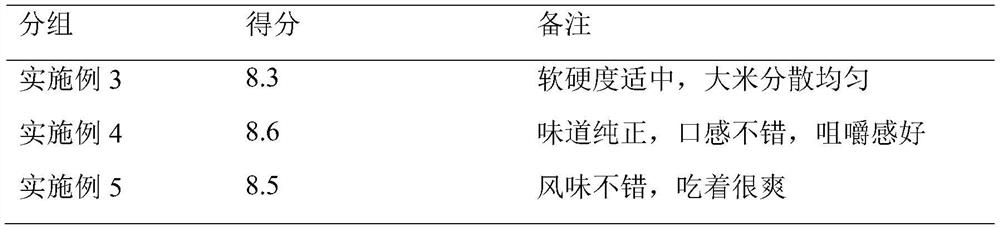

[0045] Table 1 Optimization of rice pretreatment process

[0046] Numbering soaking temperature Soaking time cooking time preprocessing effect 1 65 5 40 Rice grains are extremely soft and partially gelatinized 2 30 100 30 The rice grains are too soft and the grains are slightly gelatinized 3 40 60 20 Full swelling, good granul...

Embodiment 2

[0049] Formulated Stabilizer

[0050] Carrageenan, locust bean gum, agar, and physically modified starch are mixed according to a certain ratio to make a stabilizer, which is set aside. The composition and mixing ratio of the raw material components of the stabilizer are as follows:

[0051] Table 2 stabilizer mixture

[0052] Numbering carrageenan Locust Bean Gum agar Physically modified starch 1 12 25 40 23 2 25 20 25 30 3 22 30 20 28 4 10 20 20 50 5 23 26 20 31 6 27 28 25 20 7 40 20 20 20

[0053] In the above table, the dosage unit of various stabilizer raw materials is gram, and a variety of stabilizer materials with different compounding ratios can be prepared according to the proportions in the above table. Each mixed stabilizer was dissolved in water, and its dissolution and dispersion properties were compared, as well as the viscosity change performance of the solution. The performance o...

Embodiment 3

[0055] 1. Raw materials

[0056] Milk: 800kg, rice: 50kg, white sugar: 90kg, cream: 30kg, sweetened condensed milk: 20kg; stabilizer: 10kg, (carrageenan 2.5kg, locust bean gum 2.5kg, agar 2kg, physically modified starch 3kg).

[0057] 2. Process

[0058] Rice treatment: Warm 200kg of milk to 55°C in advance, remove impurities from 50kg of rice, rinse with water 1-2 times, drain, put into milk and soak for 30 minutes, then steam in a steamer for 30 minutes, take out for later use.

[0059] Base material preparation: Take the remaining 600kg of milk and heat it to 60°C, add sugar and stabilizer, and stir for 10 minutes; then add cream and condensed milk, stir for 10 minutes; heat up to 60°C for homogenization, and the homogenization pressure is 120bar.

[0060] Mixing sterilization: Mix the steamed rice with the base material, stir evenly, and then perform scraper sterilization. The sterilization parameter is 95°C for 10 minutes.

[0061] Cooling filling: Cool the sterilized p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com