Forming method of large-capacity oil pan

A molding method and oil pan technology, applied in the furnace type, engine lubrication, furnace and other directions, can solve the problems of poor reliability of the oil pan, limited oil storage in the deep oil shell, easy to break, etc., to improve production efficiency and good quality. rate, the effect of large oil storage volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

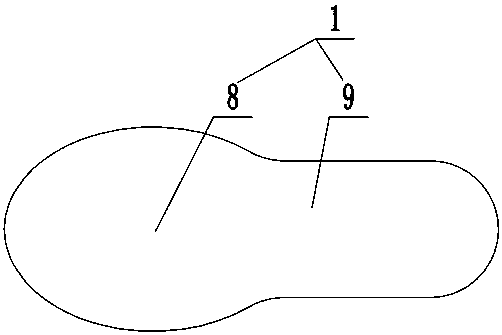

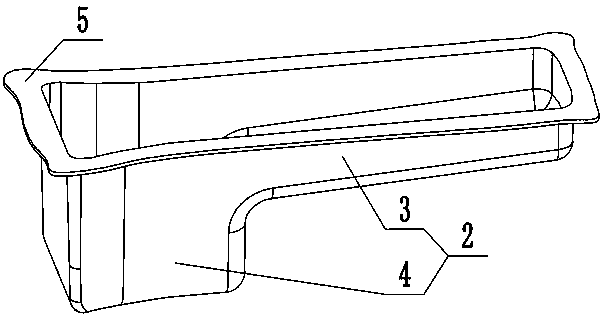

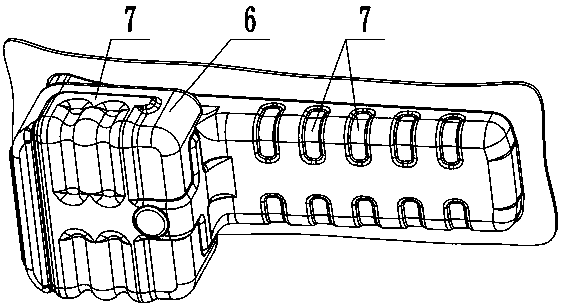

[0024] Existing large-capacity oil pans usually include a rectangular shallow oil pan 3, correspondingly, the top of the shallow oil pan 3 is provided with a rectangular opening, the opening has a set shape and size, therefore, it is convenient to remove the oil pan It is docked and installed with the installation port at the bottom of the body such as the engine. Secondly, the bottom of one end of the shallow oil shell 3 in the length direction is provided with a deep oil shell 4 that continues to sag. The function of the deep oil shell 4 is to increase the oil storage volume and deposit storage The role of sediment, cf. figure 2 As shown, since the deep oil shell 4 is continuously formed on the bottom of one end in the length direction of the shallow oil shell, the end shell wall of the deep oil shell near the end of the shallow oil shell and the end shell of the shallow oil shell at the same end The wall is preferably on one plane, and the side shell walls of the deep oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com