Trolley inspection and maintenance device

A trolley and post-detection technology, applied in the field of trolley inspection and maintenance devices, can solve the problems of workers forgetting to mark, workshop changes, etc., and achieve the effects of improving quality, stable state, and smooth return

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following is a preferred detailed description of specific embodiments of the present invention in conjunction with the accompanying drawings.

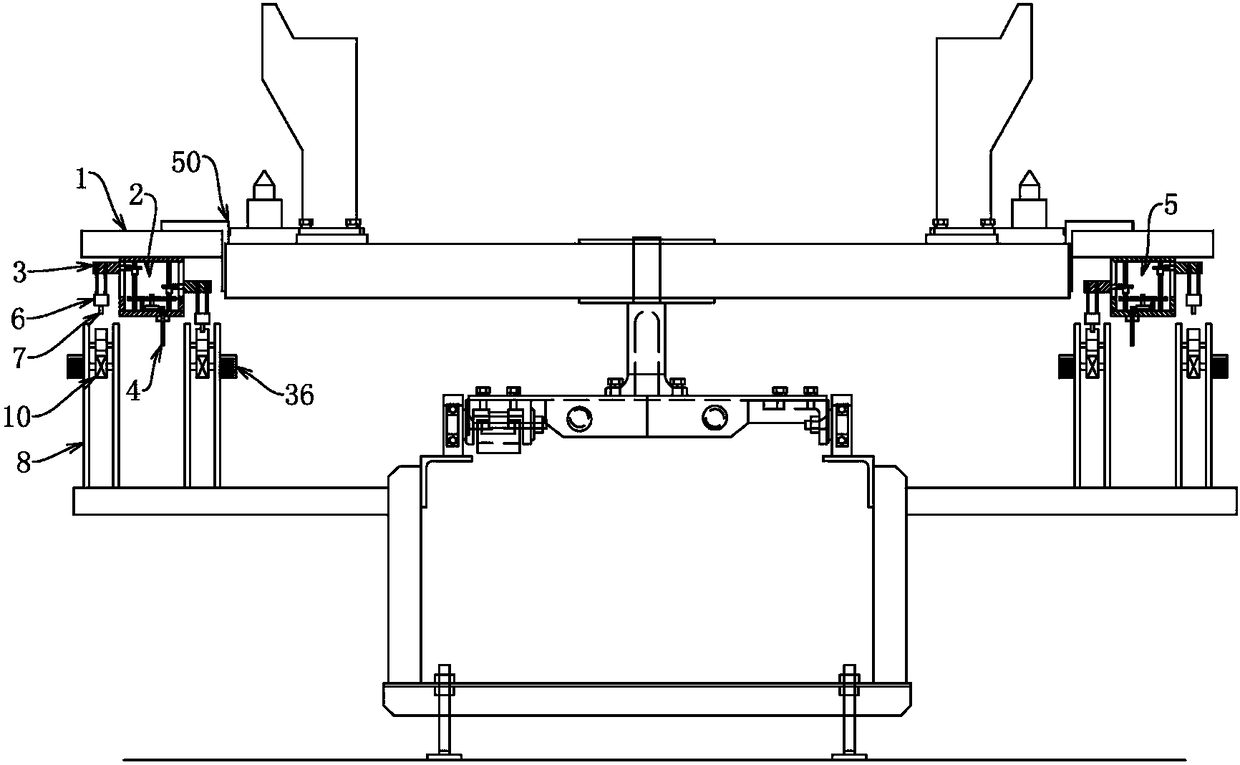

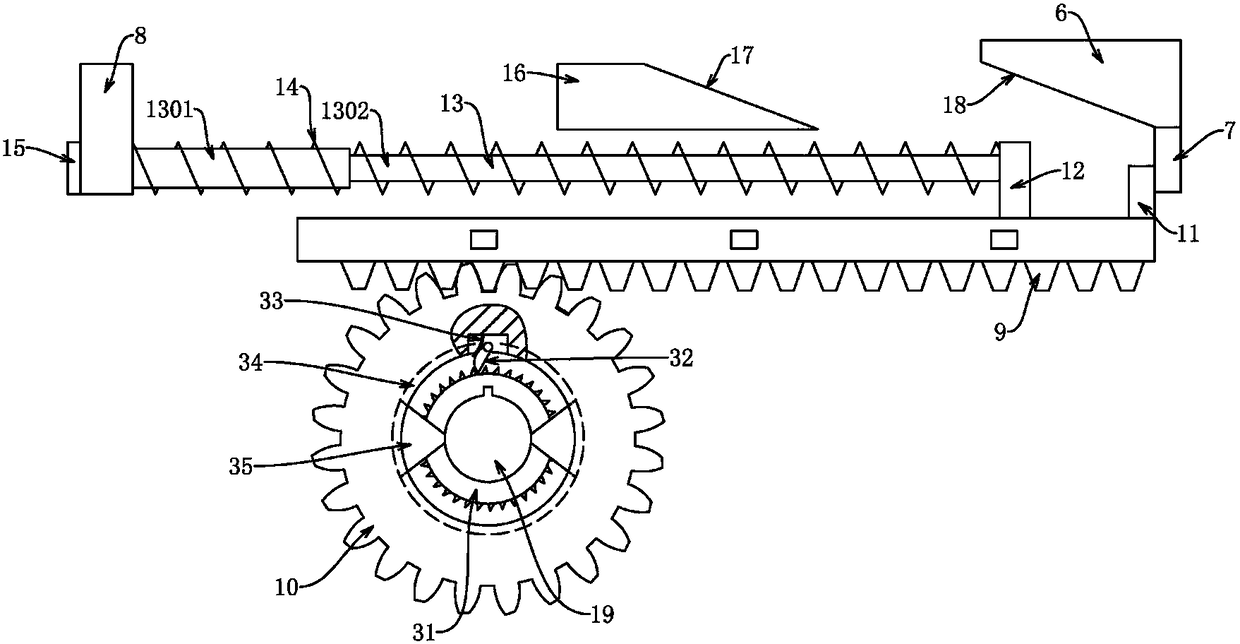

[0021] Depend on Figure 1 to Figure 8 Given, the technical solution of the present invention is to include the connecting frame 1 respectively fixed on both sides of the trolley support frame 50, and it is characterized in that, the lower end of the connecting frame 1 is fixed with a mounting shell 2, and the left and right sides of the mounting shell 2 The sides are respectively vertically slidably connected with a base plate 3, the lower end of the installation shell 2 is provided with a joystick 4 that can rotate back and forth, the inside of the installation shell 2 is equipped with a positive and negative adjustment device 5, the base plate 3 and the joystick 4 Respectively connected to the forward and reverse adjustment device 5, the forward and reverse adjustment device 5 has a structure that when the joystick 4 is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com