Ultralow-temperature urea solution for automobile and preparation method thereof

A vehicle urea, ultra-low temperature technology, applied in mechanical equipment, muffler devices, engine components, etc., can solve problems such as increased failure rate, inconvenient storage, carrying and filling, and increased vehicle costs, and achieves easy storage and widen use. range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The preparation method of the above-mentioned ultra-low temperature vehicle urea solution, the specific preparation steps are as follows:

[0023] Mix urea, ammonium and high-purity water in proportion, stir until completely dissolved at room temperature, and filter with a filter element with a filtration accuracy of 5 μm to obtain the finished product.

[0024] specific experiment

[0025] The present invention will be further explained below in conjunction with specific experimental data.

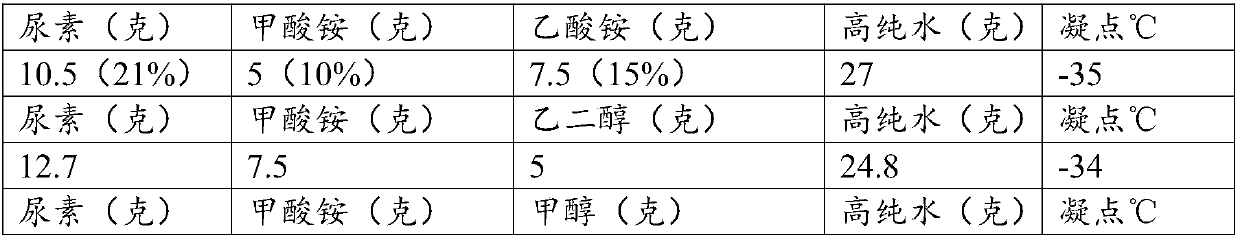

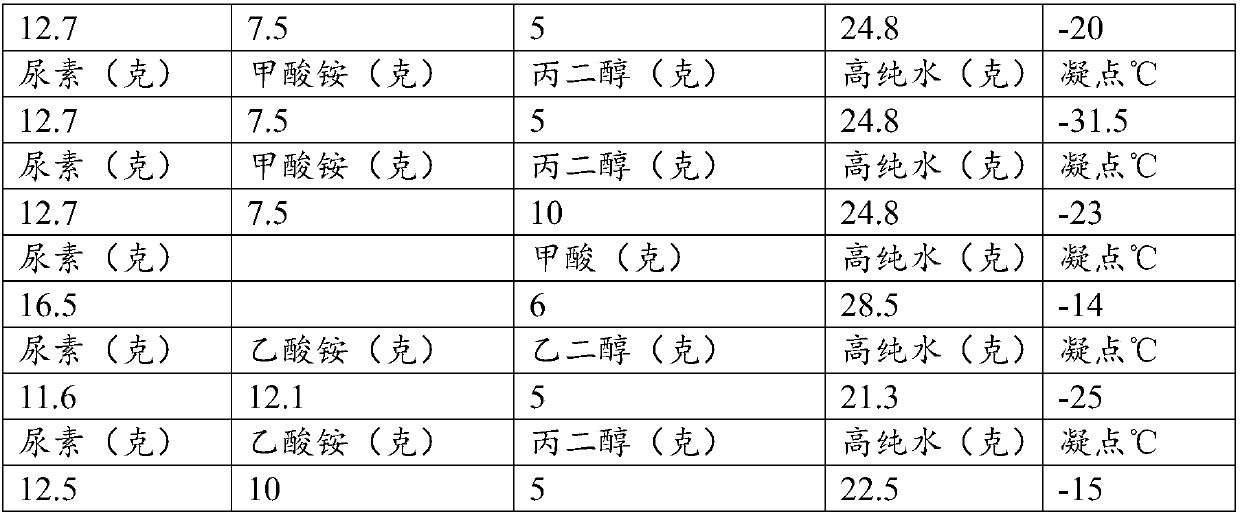

[0026] 1. Mix urea, ammonium acetate and high-purity water according to the following ratio, and measure the freezing point temperature, see Table 1 for details.

[0027] Table 1:

[0028] Urea (g)

[0029] It can be seen from the experiment that after adding ammonium acetate, the freezing point of the urea solution is generally within -20°C when the urea concentration is maintained at 32.5%, and the water content of the solution decreases as the ammonium acetate increa...

Embodiment 1

[0045] Select 21 parts of high-purity urea, 10 parts of analytically pure ammonium formate, 15 parts of analytically pure ammonium acetate, and 54 parts of high-purity water; stir at room temperature until fully dissolved, and filter under pressure with a filter element with a filtration accuracy of 5 μm to obtain a mixture solution.

[0046] After measurement, the freezing point of the mixed solution is -35°C, odorless, clear and transparent in appearance, the content of impurity elements meets the requirements of the standard, and the compatibility of plastics meets the requirements; after 4 weeks of storage at room temperature, there is no perceptible change in appearance and odor, performance indicators All tests passed. In the technical center laboratory of Chaochai Power Co., Ltd., the ESC working condition test and the WHTC working condition test were carried out on the diesel engine bench with a displacement of 8.6 liters. The reducing agent was processed by the SCR pos...

Embodiment 2

[0048] Select 27 parts of high-purity urea, 8.4 parts of analytically pure ammonium formate, 12.6 parts of analytically pure ammonium acetate, and 45 parts of high-purity water; stir at room temperature until completely dissolved, and filter under pressure using a filter element with a filtration accuracy of 5 μm to obtain a mixture solution.

[0049] After measurement, the freezing point of the mixed solution is -30.5°C, odorless, the appearance is clear and transparent, the content of impurity elements meets the requirements of the standard, and the compatibility of plastics meets the requirements; after 4 weeks of storage at room temperature, there is no perceptible change in the appearance and smell, and the performance index All tests passed. In the technical center laboratory of Chaochai Power Co., Ltd., the ESC working condition test and the WHTC working condition test were carried out on the diesel engine bench with a displacement of 8.6 liters. The reducing agent was p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com