Turbocharger

A turbocharger and turbine technology, which is applied to instruments, sounding equipment, air intake mufflers, etc., can solve the problems of reducing the attenuation effect and sound attenuation, and achieve the effect of improving the sound attenuation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

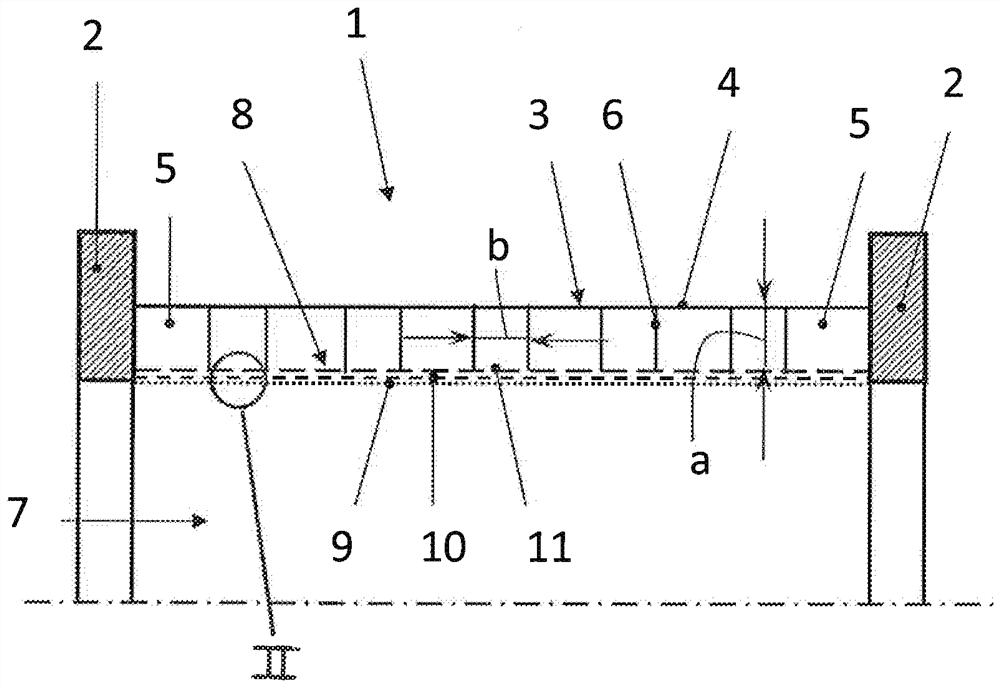

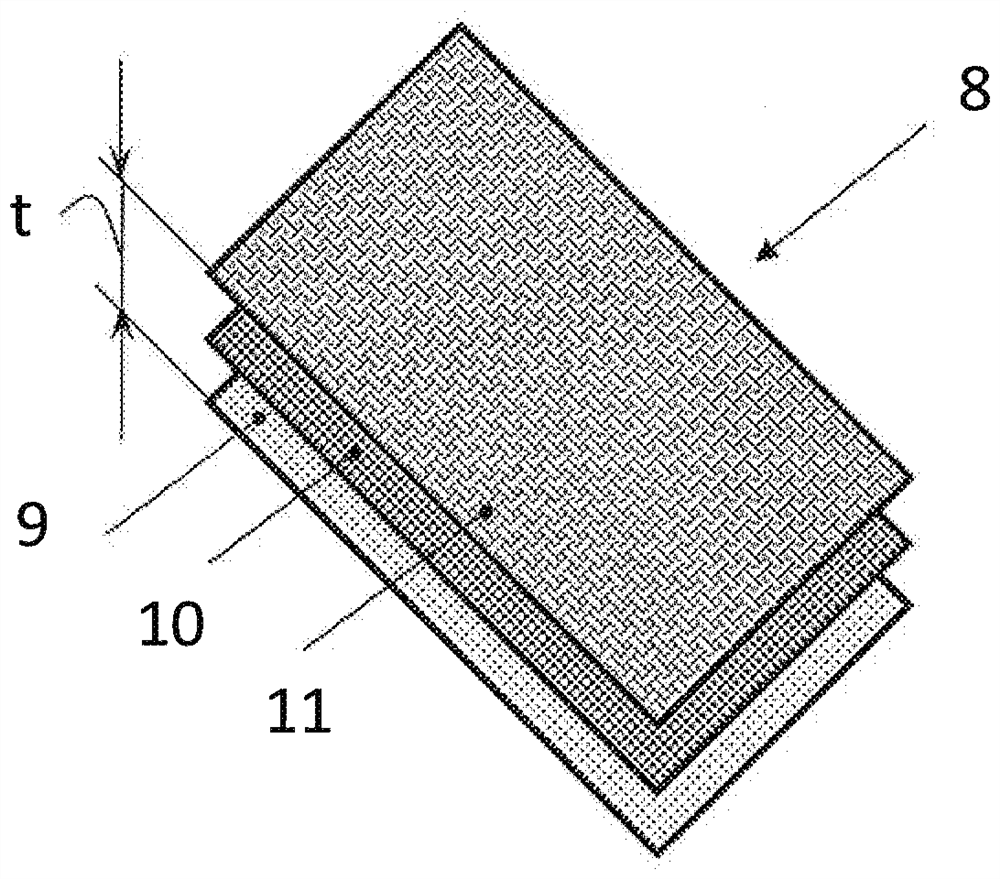

[0028] The invention presented here relates to turbochargers. The basic structure of a turbocharger is familiar to those skilled in the art. The turbocharger thus has a turbine for the expansion of the first medium, in particular for the expansion of the exhaust gas, where energy is obtained. Furthermore, the turbocharger comprises a compressor for the compression of the second medium, in particular for the compression of charge air, wherein here the energy obtained during the expansion of the first medium in the turbine is regenerated in the compressor in use.

[0029] Turbochargers have different flow directing components. These include in particular the so-called discharge housings of the compressors of the exhaust-gas turbocharger. At least one flow guiding element of the turbocharger is provided with a silencer 1 .

[0030] figure 1 A schematic section through a silencer 1 is shown, which cooperates with a flow guiding element of a turbine, for example with a helical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com