Adjustable magnetic levitation oil mist sealing device

A sealing device and floating sealing ring technology, applied in the direction of engine sealing, electromechanical devices, electric components, etc., can solve the problems of leaf spring failure, floating sealing ring jumping, grinding shaft, etc., to prevent eccentric wear and uniform force. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

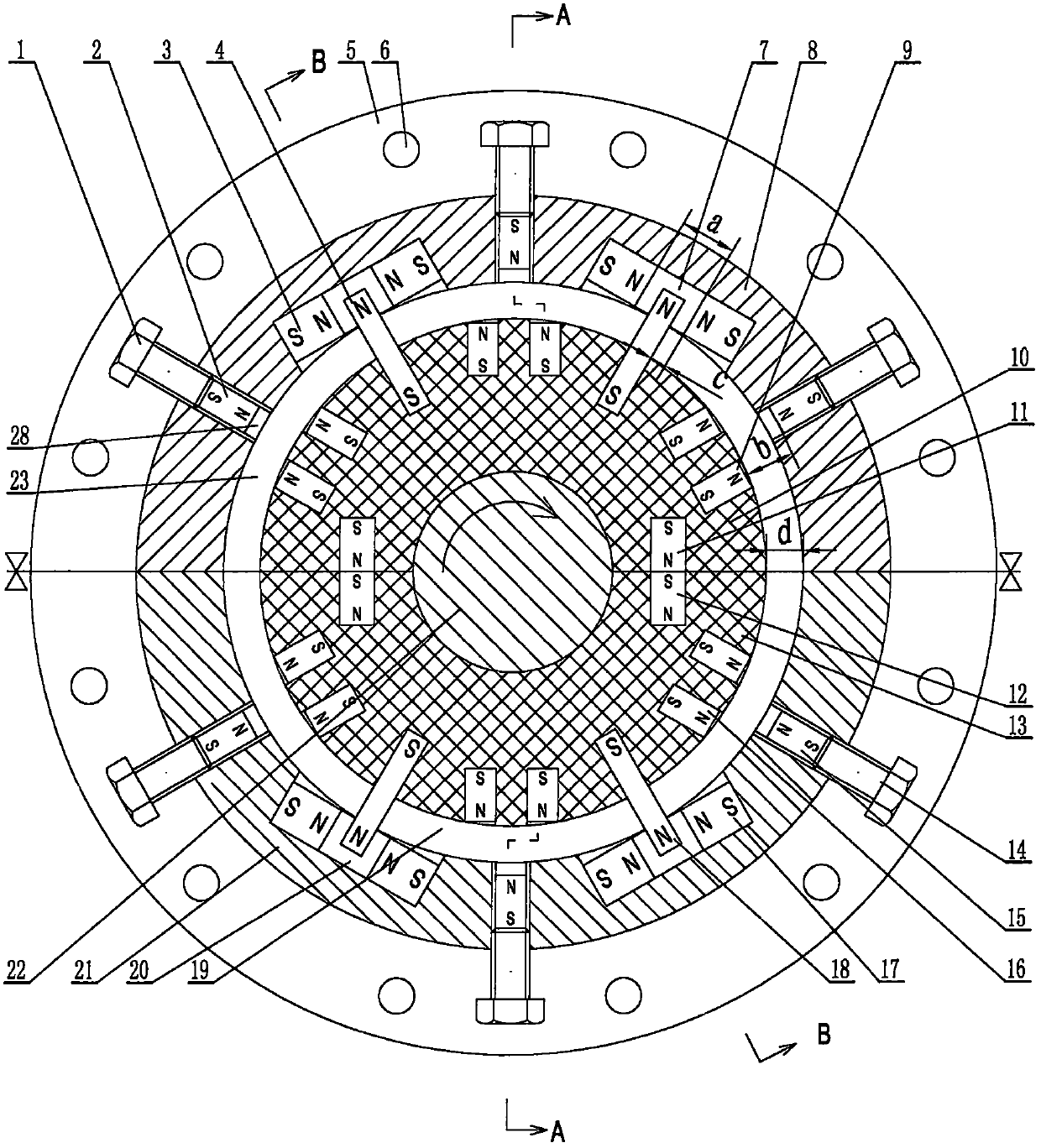

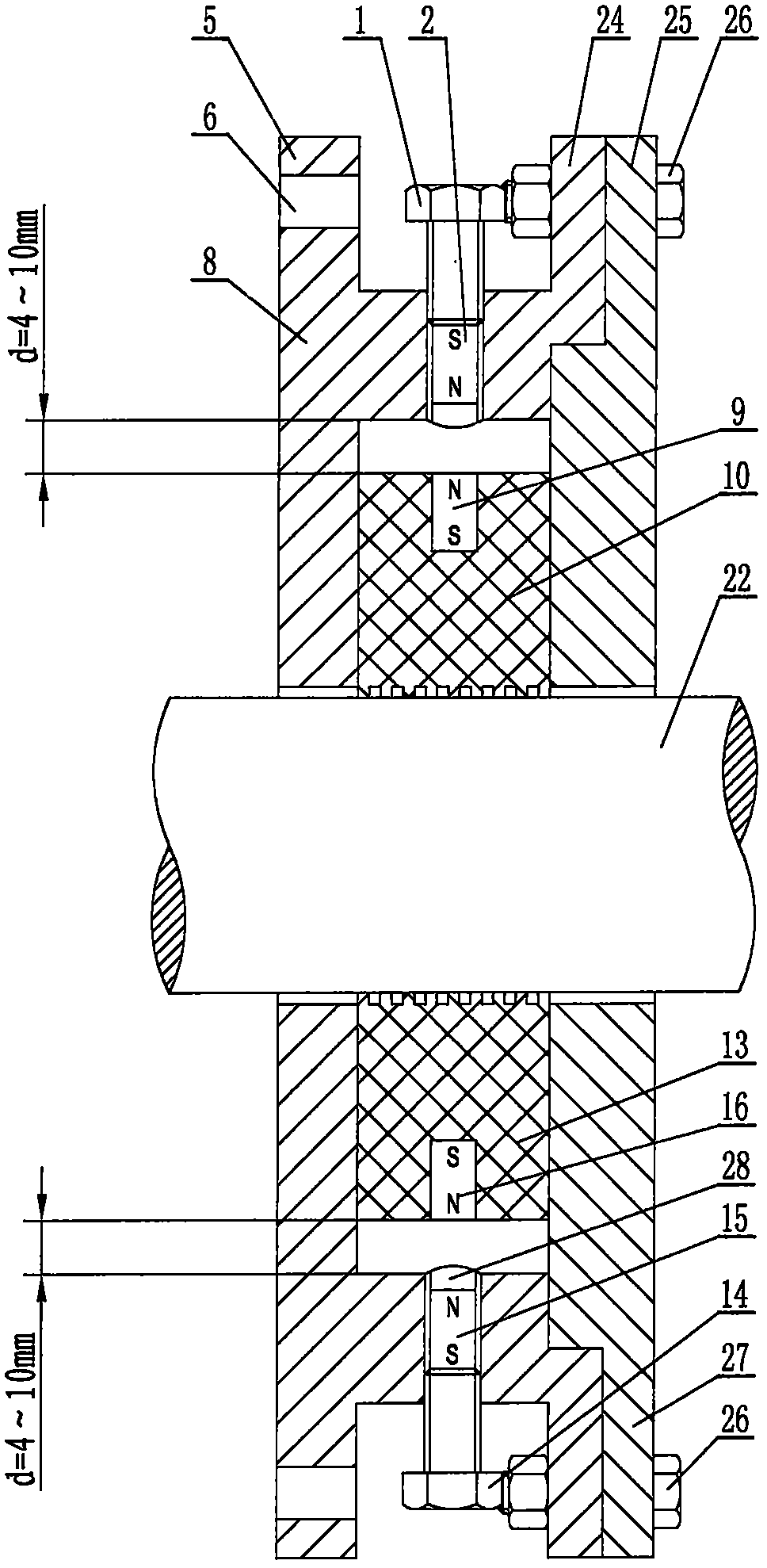

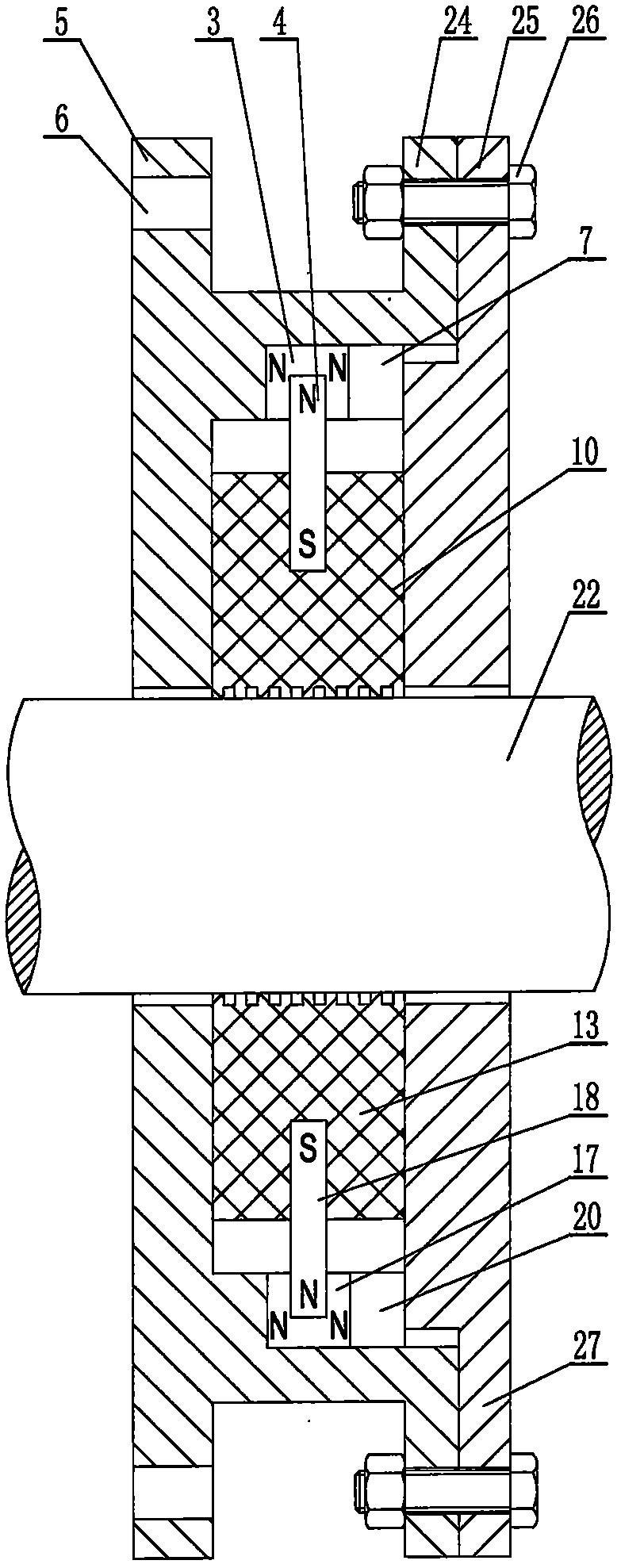

[0023] Screw the upper adjustment screws 1 with the upper adjustment magnetic columns 2 fixed at the front ends into the adjustment screw holes 28 evenly distributed on the upper valve seat ring 8, and the S poles of the upper adjustment magnetic columns 2 are fixed on the ends of the upper adjustment screws 1 . The inner magnetic blocks 3N poles of the paired upper limit are relatively fixed on both sides of the upper limit groove 7, and the surface distance of the two N poles is adjustable from 20 to 30 mm, and the upper limit groove 7 is symmetrically processed. Embed one or a pair of upper ring magnetic columns 9 corresponding to the position of the upper adjustment magnetic column 2 in parallel into the outer diameter of the upper floating seal ring 10, and the N poles of the upper ring magnetic columns 9 correspond to the N poles of the upper adjustment magnetic column 2; The S pole of the outer magnetic strip 4 of the upper ring is embedded in the outer diameter of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com