Risk assessment method for collapsible loess based on multi-angle laying of simulated pipelines

A collapsible loess and dangerous technology, applied in the field of pipeline embedding in collapsible loess areas, can solve problems such as difficulty, high cost, and long test period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

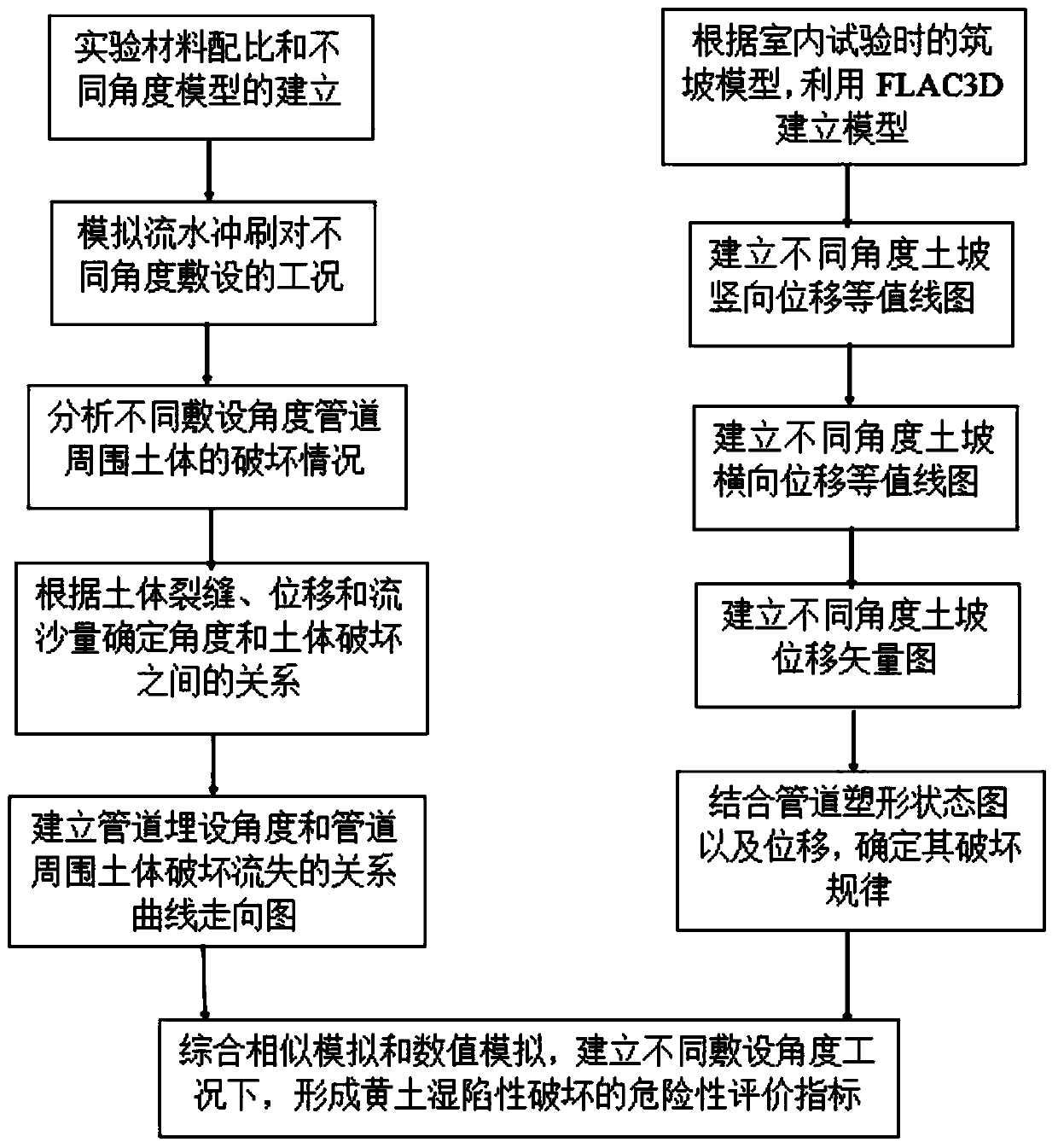

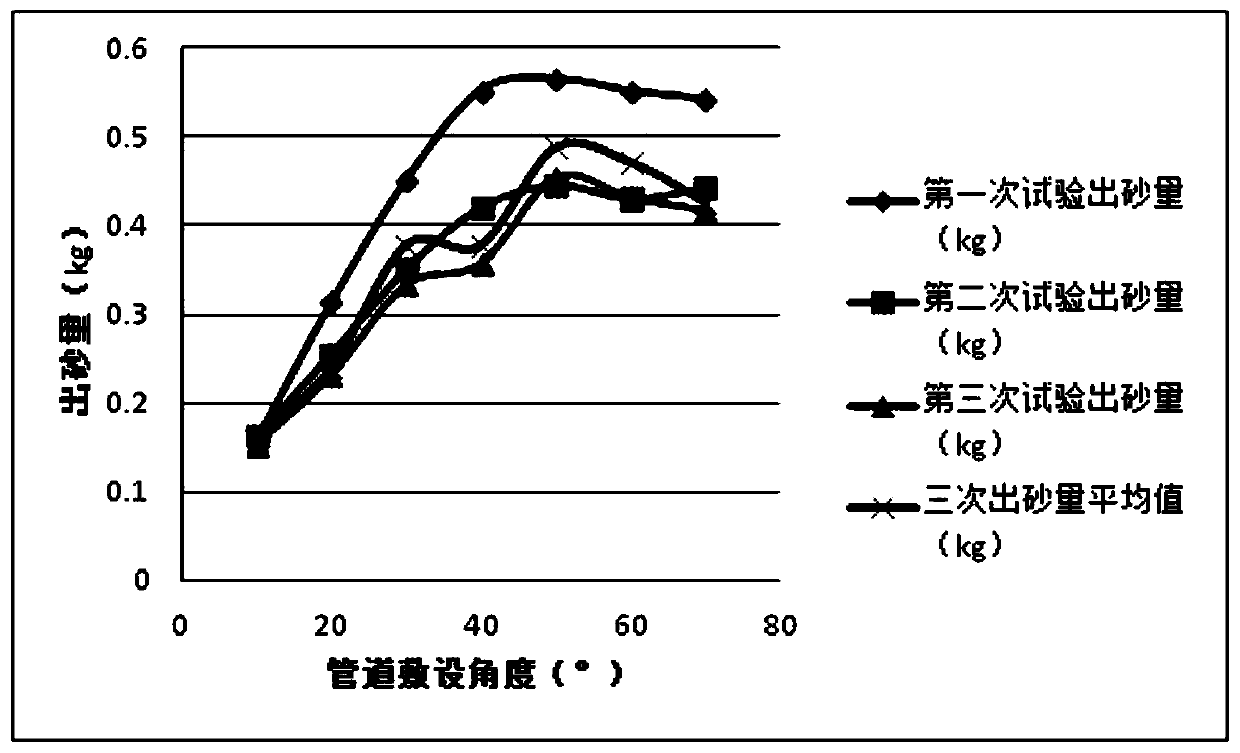

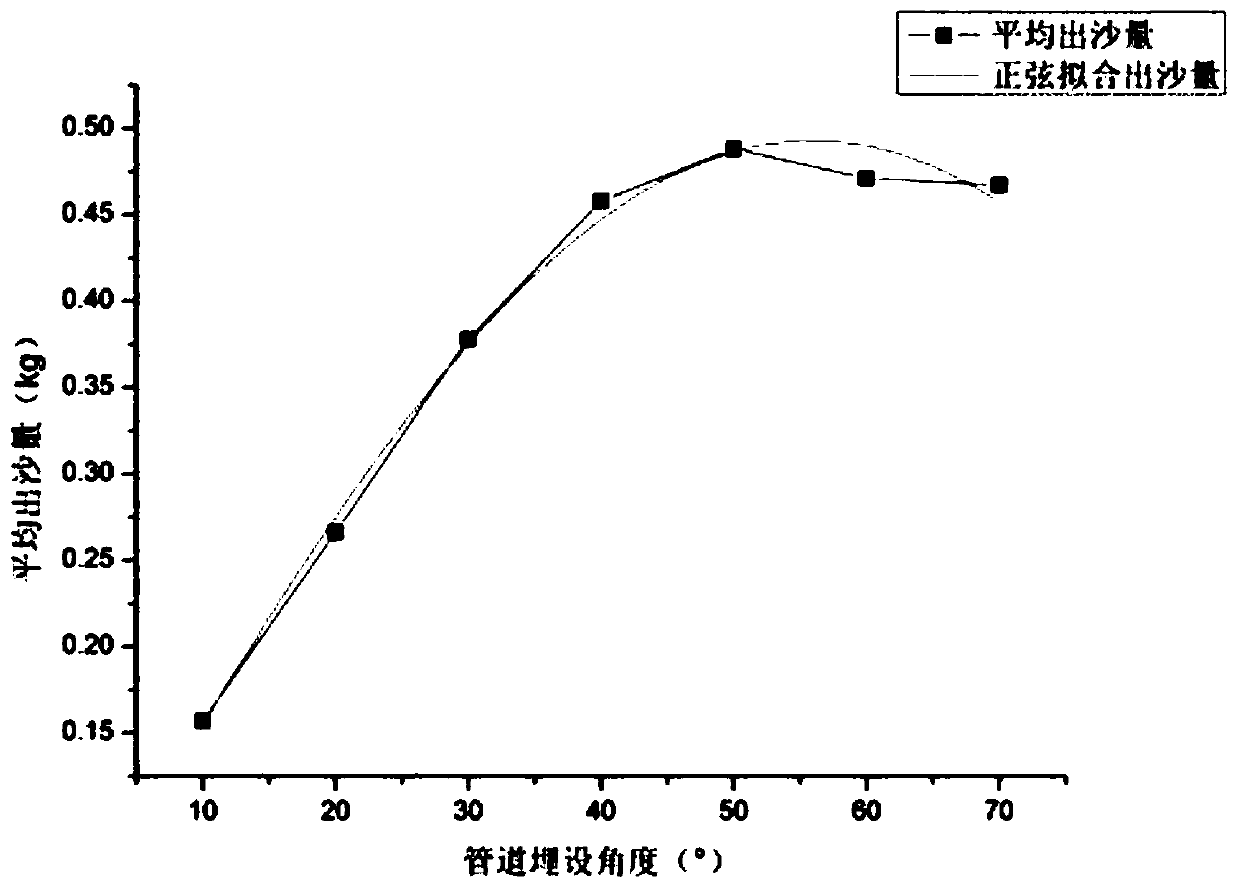

[0084] (1) The ratio of experimental materials and the establishment of different angle models; according to the slope model during the indoor test, use FLAC3D to establish the model;

[0085] According to the test requirements, select and prepare the test materials suitable for the experiment, and make the main material of the model according to the ratio; according to the pipe embedding angle, design the size and angle of the model, make the main model; the pipe embedding is excavated according to the geometric similarity ratio, The burial angles are respectively 15°, 30°, 45°, and 60°, and the top and bottom of the pipeline should be exposed to the soil when burying. It mainly simulates and calculates the force analysis of the pipeline and the upper soil after the soil around the pipeline in the soil slope encounters water and soil loss. Four angles were compared in this simulation, namely 30°, 40°, 50°, and 60°. The specific implementation steps are as follows:

[0086] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com