Intelligent production management system and method

A management system and intelligent production technology, applied in the field of information processing, can solve problems such as extrusion of semi-finished products or raw materials, waste, and impact on production progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

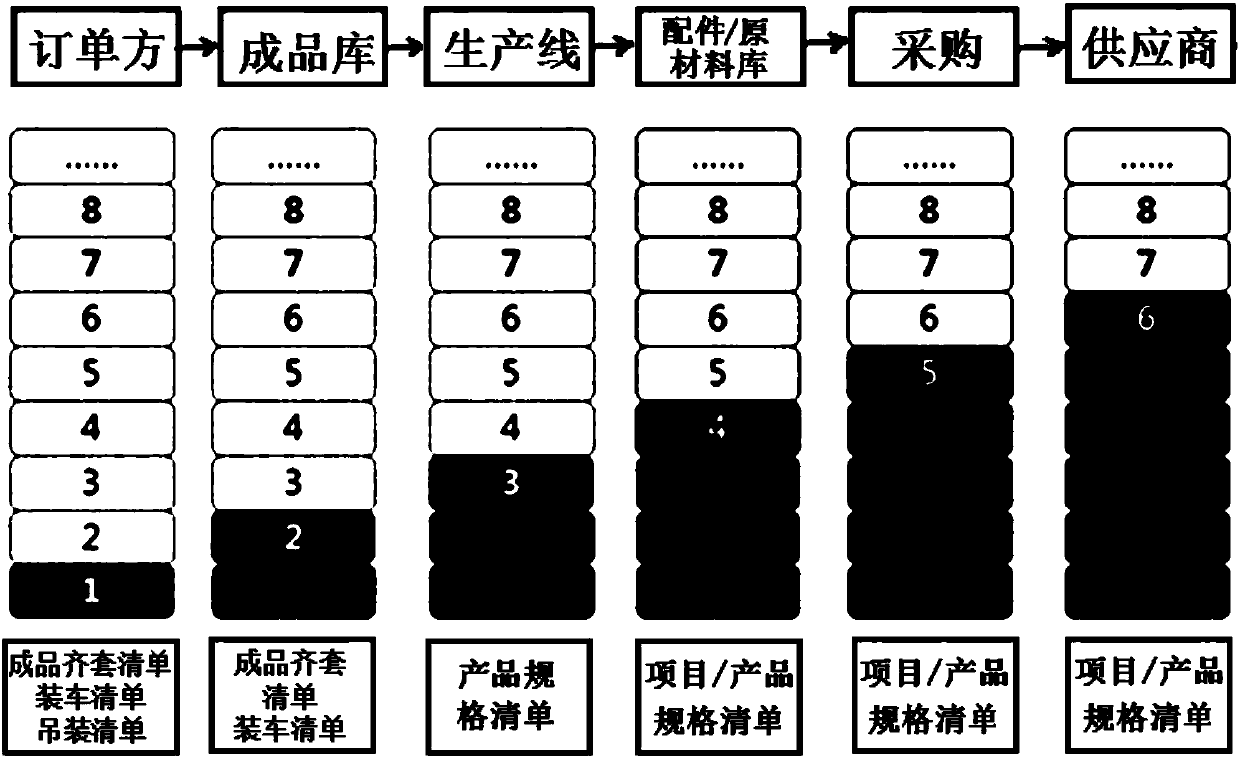

[0031] see figure 1 , the intelligent production management system of the present invention includes an orderer module, a finished product library module, a production line module, an accessory / raw material library module, a procurement module and a supplier module arranged in sequence, and in each of the above modules, a batch of The amount of raw materials or parts required for the finished product is used as a layer unit, and a module is divided into n layer units, where n is a natural number other than 0. Among the modules arranged in sequence, the previous module starts to carry out the nth layer unit During the production and preparation activities, the supply demand information is sent to the next module. The supply demand information sent by the previous module is automatically sent by the server management system of the intelligent production management system or manually transmitted to the latter module. The identification process in the latter module After the modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com