Machining method for aero-engine tight-sealing labyrinth disc

An aero-engine and grate-sealing technology, which is applied to engine components, machines/engines, mechanical equipment, etc., can solve the problems such as the inability to guarantee the size of the grate disc and the difficult deformation of the grate disc, so as to ensure dimensional stability and consistency. performance, control cutting deformation, and enhance rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] see Figure 2-Figure 7 , The processing method of an aeroengine sealing grate disk of the present invention includes the following steps:

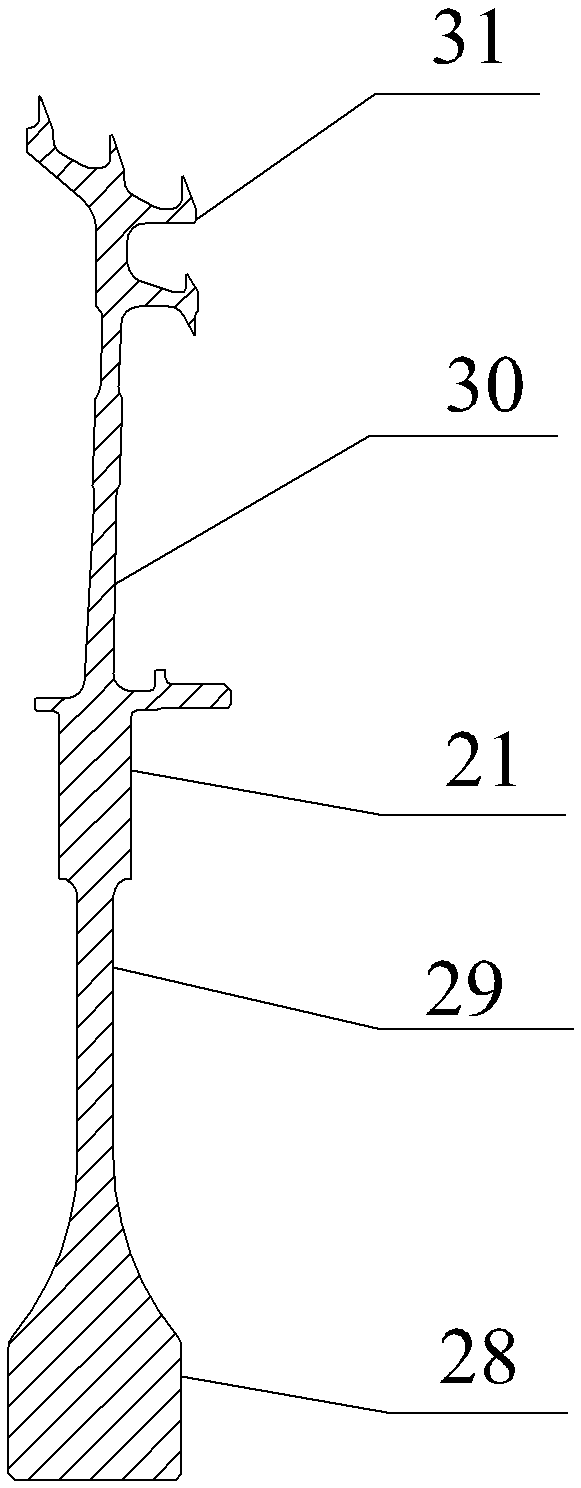

[0024] Step 1. Design the part corresponding to the grate teeth of the grate disc blank D as the first process edge 1, and design the part corresponding to the upper web of the grate disc blank D as the second process edge 2, such as figure 2 Shown

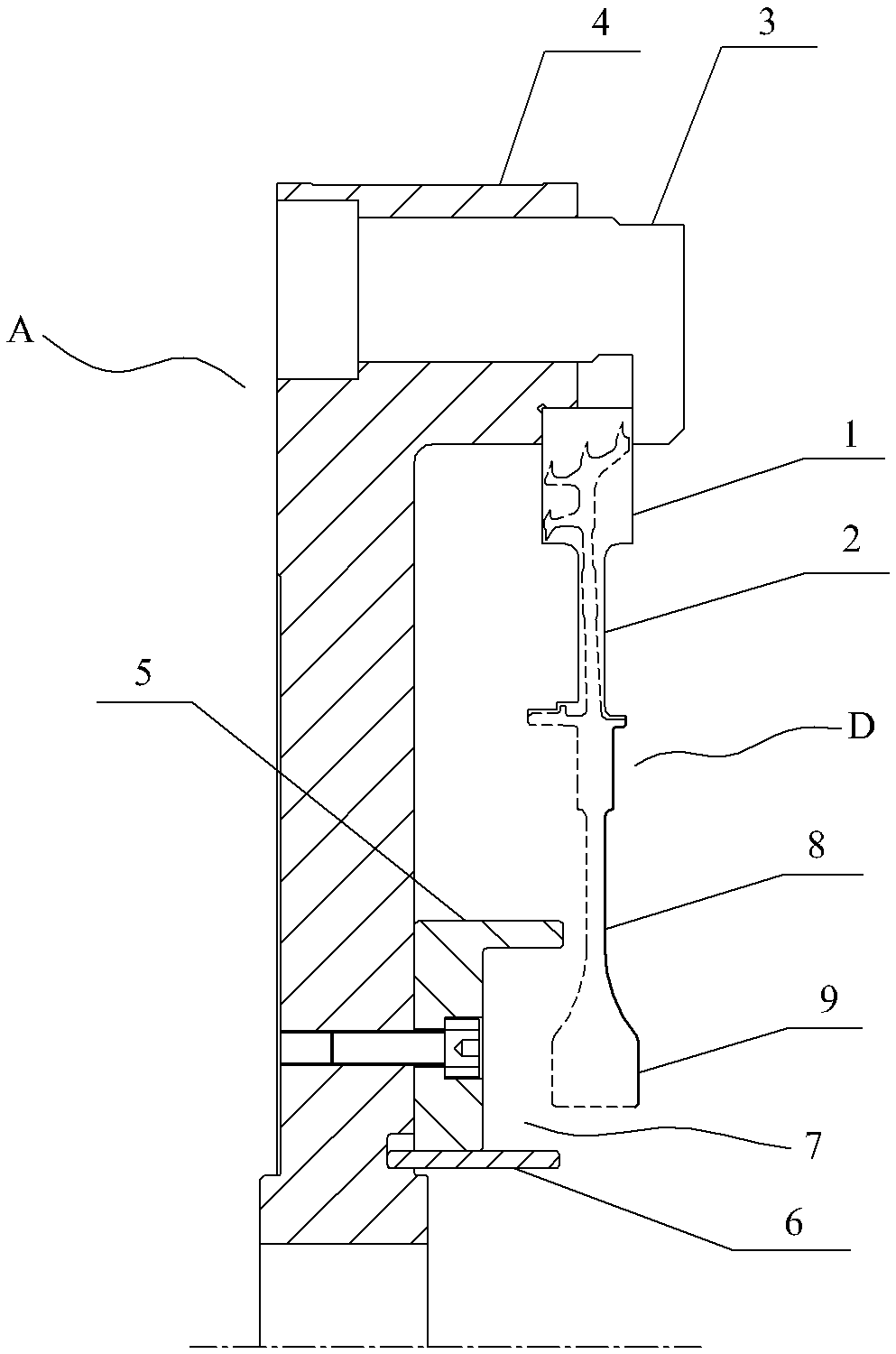

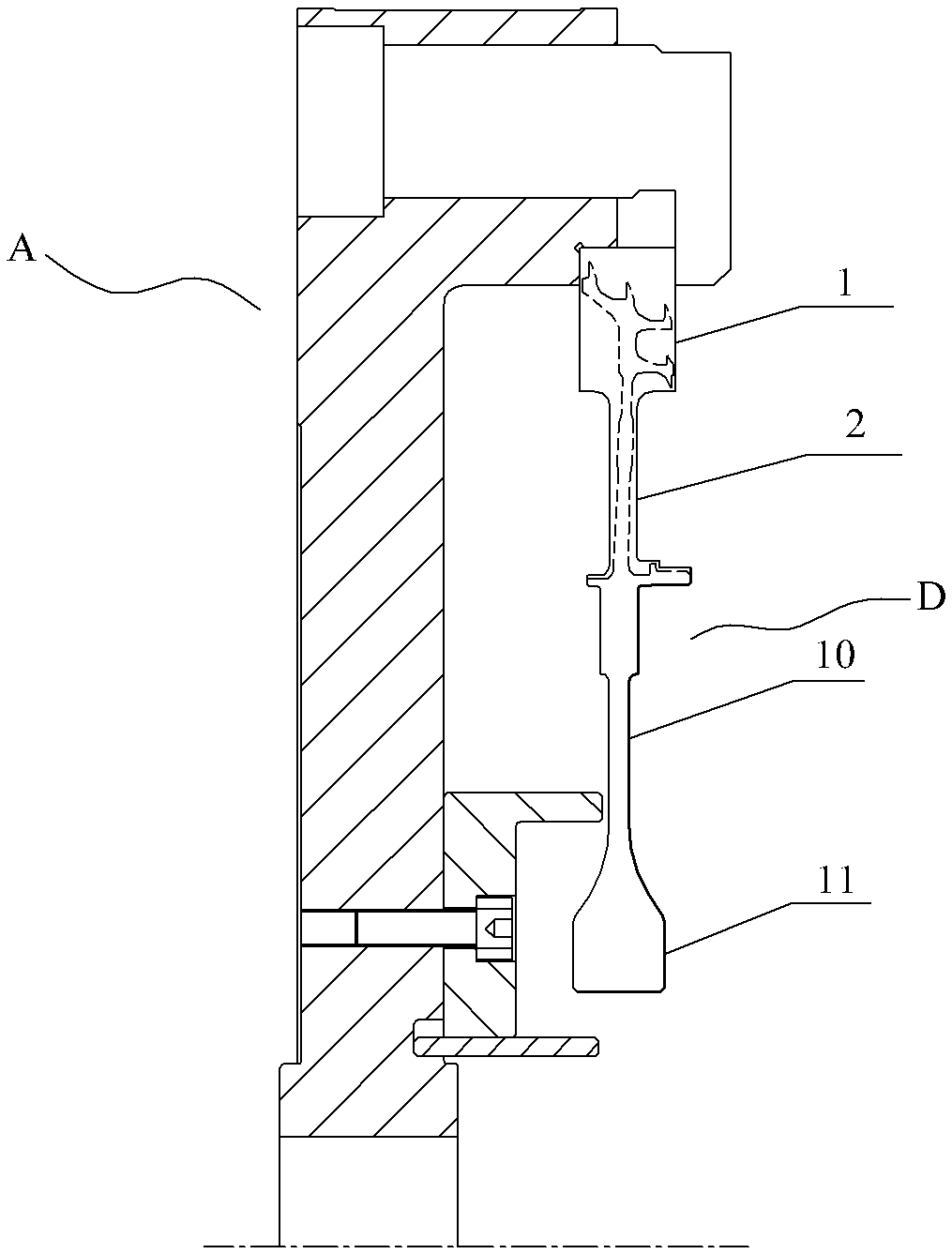

[0025] Step 2, first use the hook-shaped pressing plate 3 of the first process edge fixture A to press and position the first process edge 1 on the first fixture bottom plate 4, and pour into the groove 7 enclosed by the auxiliary support ring 5 and the baffle 6 The low melting point alloy is used to support the hub part of the grate disc blank D (other support methods such as adjustable support or elastic support can also be used), and then process the front face 8 of the lower spoke plate and the front face 9 of the hub, such as figure 2 As shown by the bold line in the middle (the dotte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com