Multi-task teaching control method and system

A control method and multi-task technology, applied in the direction of program control manipulators, manufacturing tools, manipulators, etc., can solve the problems of poor versatility and difficulty in adapting to process changes, and achieve the effect of independent work and controllability at the same time, reducing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

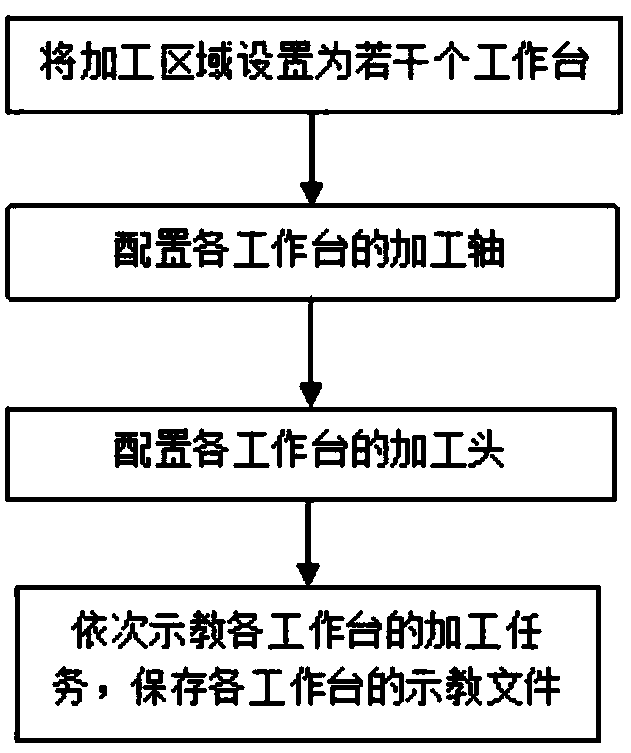

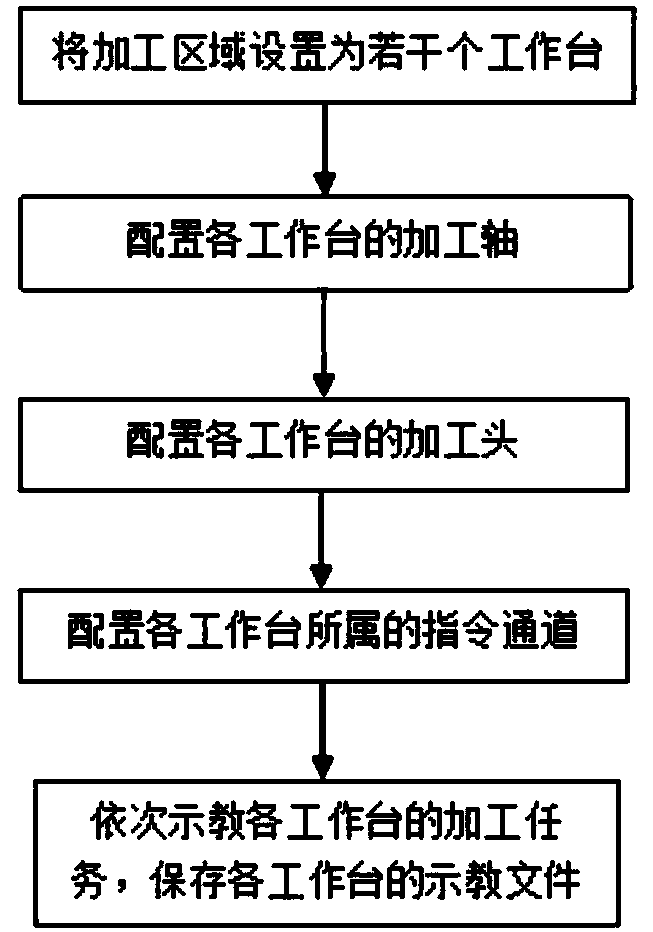

Method used

Image

Examples

example 1

[0038] Example 1: Independent double workbench, a non-standard equipment developed by a customer. There is a processing head on the upper and lower sides of the equipment, and the upper and lower processing heads are each controlled by 3 axes. To process a full-page workpiece, the processing head is first processed. Then the workpiece is turned over and processed by the processing head below. Under normal working conditions, two workpieces are being processed at the same time. For this kind of equipment, we define the upper 3 axes as workbench 1: X1\Y1\Z1, and the lower 3 axes as workbench 2: X2Y2Z2. The upper and lower processing are taught independently, the upper processing teaching is switched to workbench 1 for teaching, and the lower processing teaching is switched to workbench 2 for teaching. The specific control process is as follows:

[0039] S11: Configure workbenches 1 and 2, configure axis 1, 2, and 3 as the X, Y, and Z axes of workbench 1, and configure axis 4, 5, ...

example 2

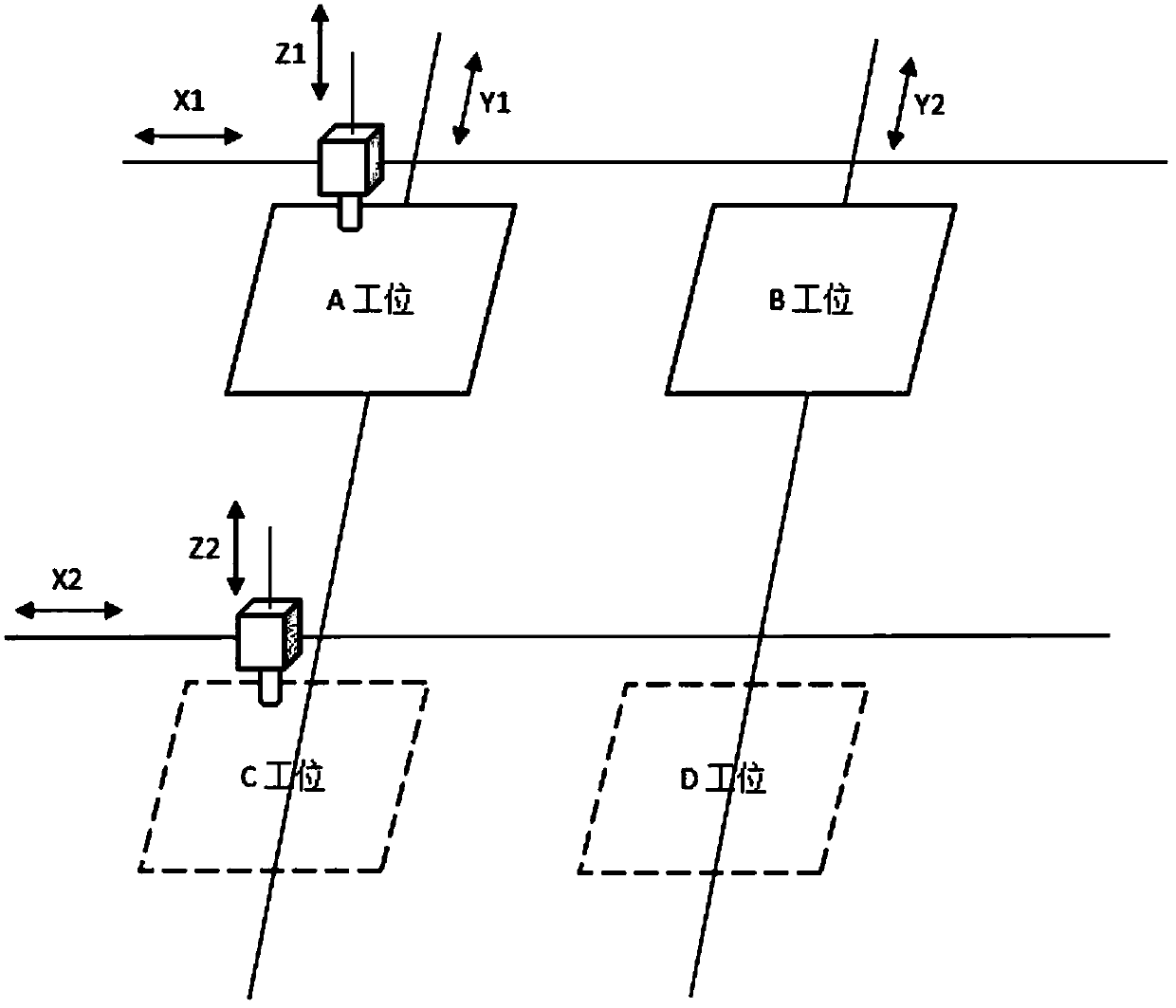

[0049] Example 2, multi-table processing, such as image 3 As shown, the processing equipment includes A station, B station, C station and D station, and 2 processing heads. The specific control process is as follows:

[0050] S21: Configure workbenches 1, 2, 3, 4, configure axis 1, 2, and 3 as the X, Y, and Z axes of workbench 1, and configure axis 1, 5, and 3 as X, Y, and Y of workbench 2. For the Z axis, the 4, 2, and 6 axes are arranged as the X, Y, and Z axes of the table 3, and the 4, 5, and 6 axes are arranged as the X, Y, and Z axes of the table 4.

[0051] S22: Switch to the teaching interface and create a teaching file to be executed on command channel 1. At this time, the software creates a teaching file in command channel 1. At this time, the teaching file is not associated with the workbench. At this time, command channel 1 is set as the current operation command channel.

[0052] S23: Teaching the processing program of station A. Switch to workbench 1 in the teaching...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com