Efficient 3DP powder laying printing equipment and powder laying printing method thereof

A printing equipment and powder spreading technology, applied in the field of 3D printing, can solve the problems of low printing efficiency, achieve the effect of reducing printing cost, reducing waiting time, and increasing the time of simultaneous work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

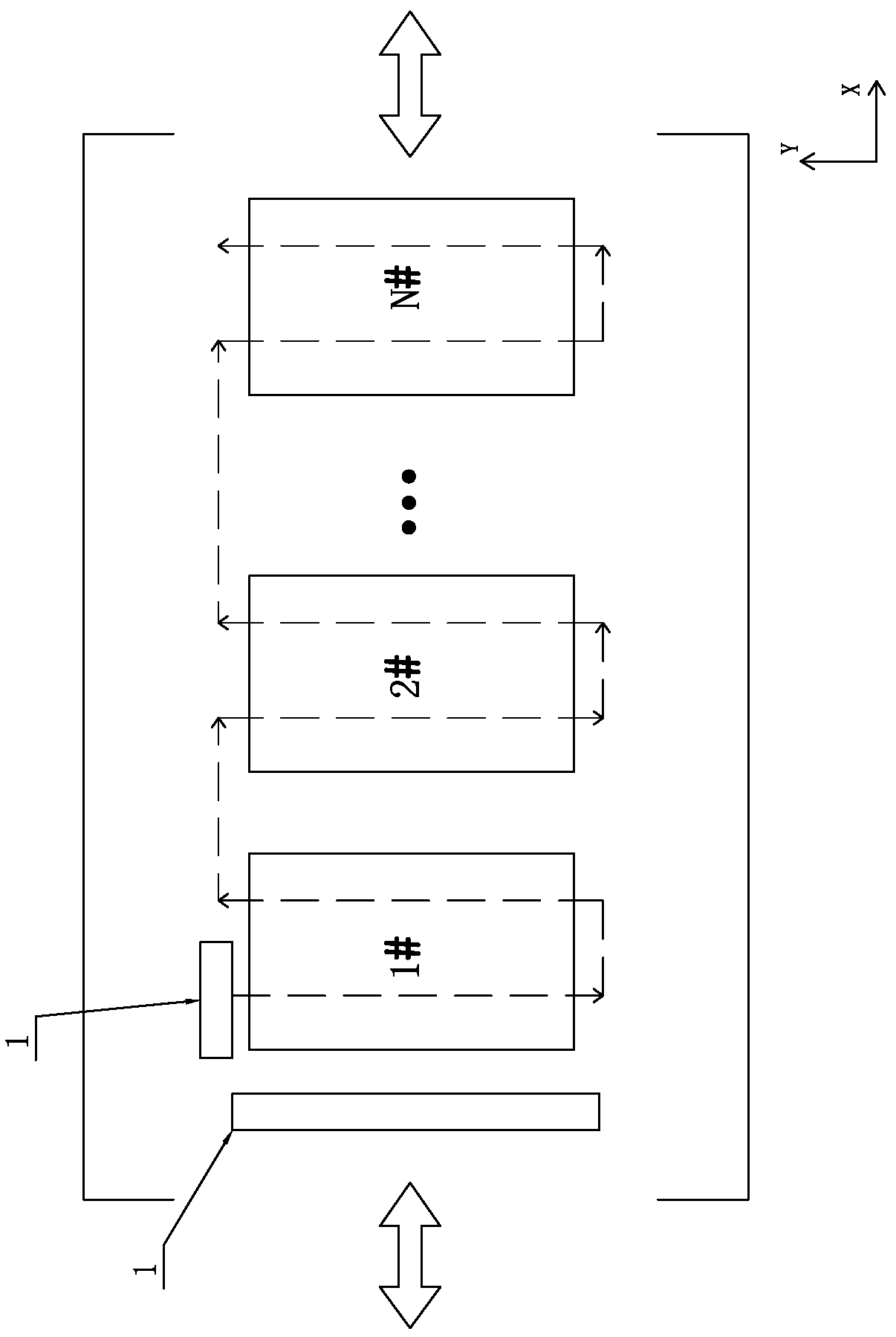

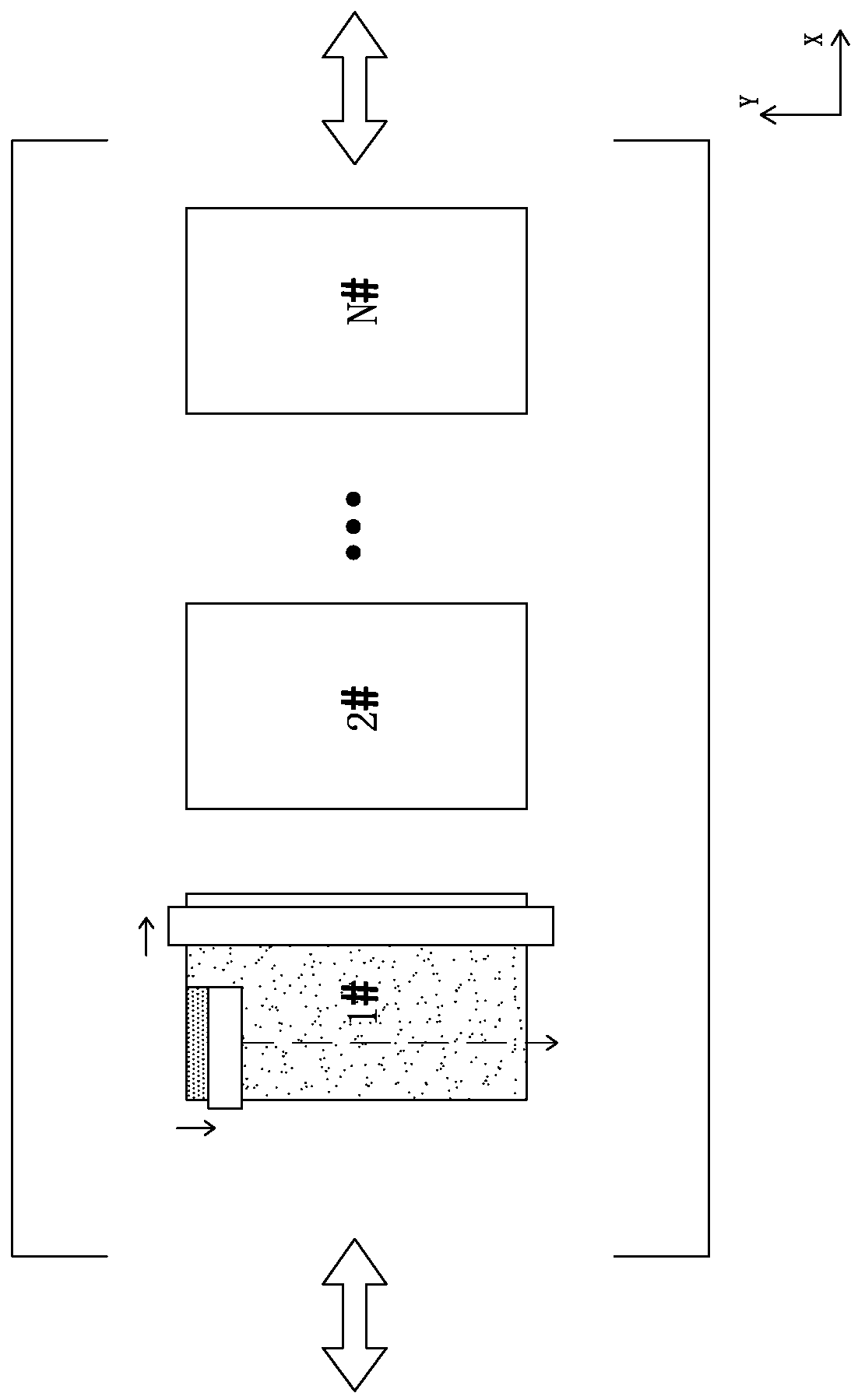

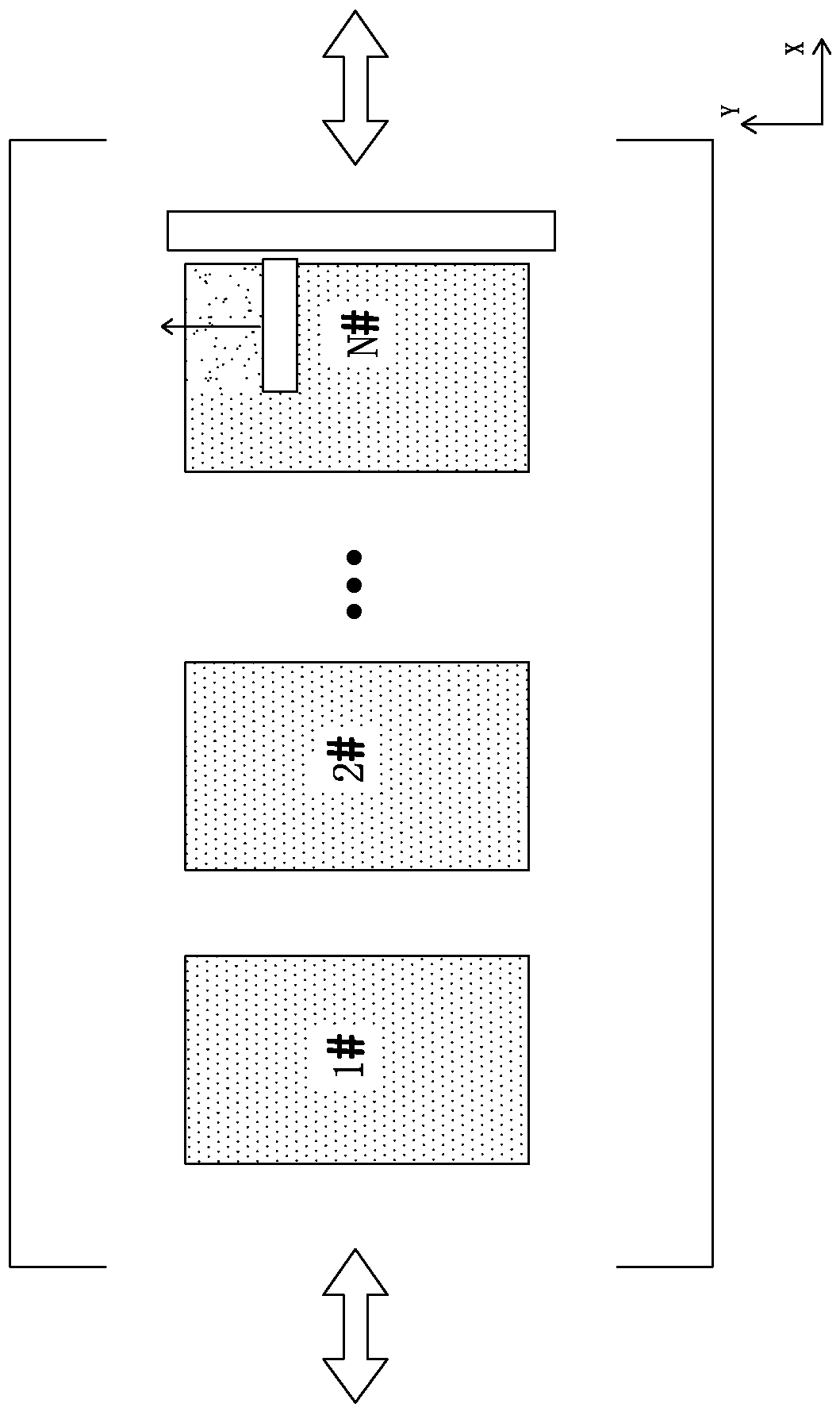

[0023] Such as Figure 1-Figure 5 Shown is the high-efficiency 3DP powder spreading printing equipment of the present invention, which includes two or more printing platforms arranged in sequence along the X-axis direction. Each printing platform can realize the lifting action through the control of the lifting device, and each printing platform is equipped with a corresponding Rectangular printing areas, respectively 1# printing area, 2# printing area...N# printing area; each printing area shares a powder spreading device 1 and a common printing head 2 arranged above each printing platform; powder spreading device 1 The powder spreading direction is the X-axis direction which is consistent with the arrangement direction of the printing area, and the powder spreading device 1 is a two-way powder spreading device, which can reciprocate powder spreading along the X-axis direction; the printing direction of the print head 2 is the same as the powder spreading direction. The direc...

Embodiment 2

[0029] This embodiment is a method for performing 3DP high-efficiency powder-coating printing on the high-efficiency 3DP powder-coating printing device implemented above, which specifically includes the following steps:

[0030] 1) if figure 1As shown, 1#, 2#...N# printing platforms are arranged sequentially along the X-axis direction at the 3D printing production site, and 1#, 2#...N# printing areas are respectively set on each printing platform, and the position of the powder spreading device 1 is adjusted. , so that it is located at the starting position outside the 1# printing area; then adjust the position of the print head 2 so that it is located at the starting position outside the 1# printing area along the Y-axis direction;

[0031] 2) Start the powder spreading device 2, so that the powder spreading device 2 starts from the 1# printing area and spreads powder to each printing area in sequence along the powder spreading direction, until the powder spreading of the N# ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com