Vehicle control method based on power battery service life optimization

A power battery, vehicle control technology, applied in hybrid vehicles, motor vehicles, data processing management, etc., can solve the problems of high power battery price and high cost of electric vehicles, and achieve the effect of prolonging service life and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0026] This method is applicable to both hybrid vehicles and pure electric vehicles. The following uses a hybrid PHEV vehicle as an example to illustrate.

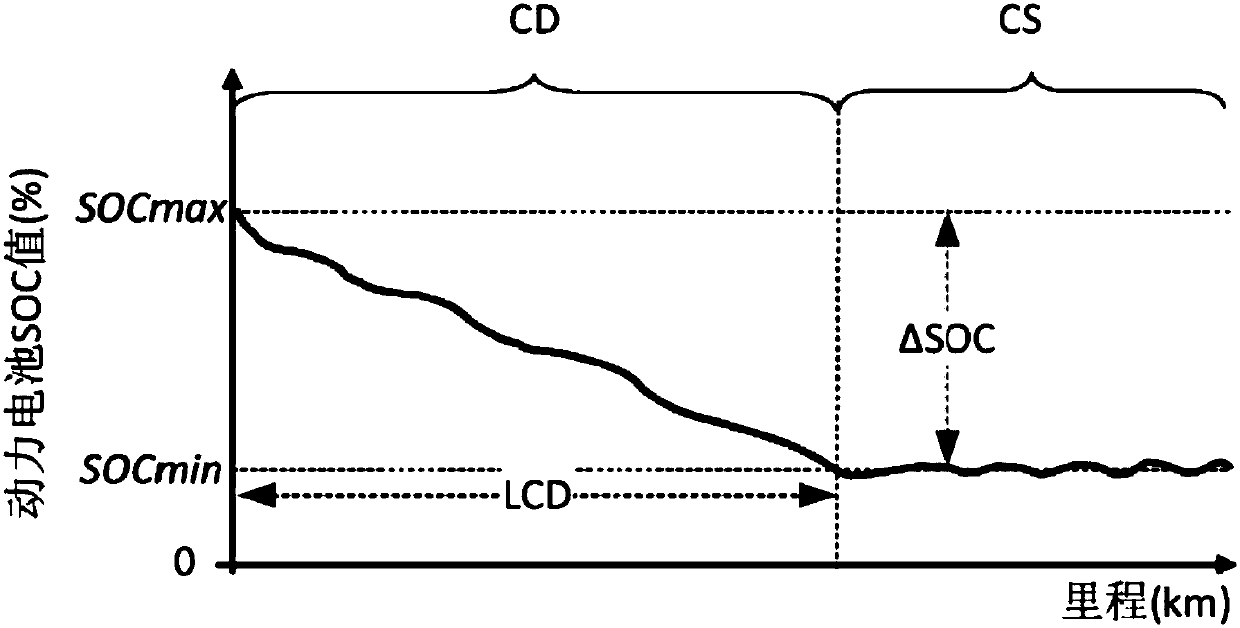

[0027] Such as figure 1 As shown, the hybrid vehicle divides the operation mode into two stages according to the SOC state of the power battery, namely the charge depleting (CD) stage and the charge sustaining (CS) stage. In the CD stage, usually the power battery alone or together with the generator set provides vehicle drive power. In the CS stage, the vehicle control method keeps the SOC within a narrow window to ensure the service life of the power battery. LCD is the mileage of the vehicle in the CD stage. Vehicle control methods are divided into the following two cate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com