Light bar transmission device

A transmission device and light strip technology, which is applied in the direction of transportation and packaging, conveyors, conveyor objects, etc., can solve the problems of increased accident risks for personnel, inability to meet production arrangements for fixed-post operations, and low efficiency, so as to reduce frequent manpower operations, The effect of reducing the transport load of employees and avoiding personnel errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing and example.

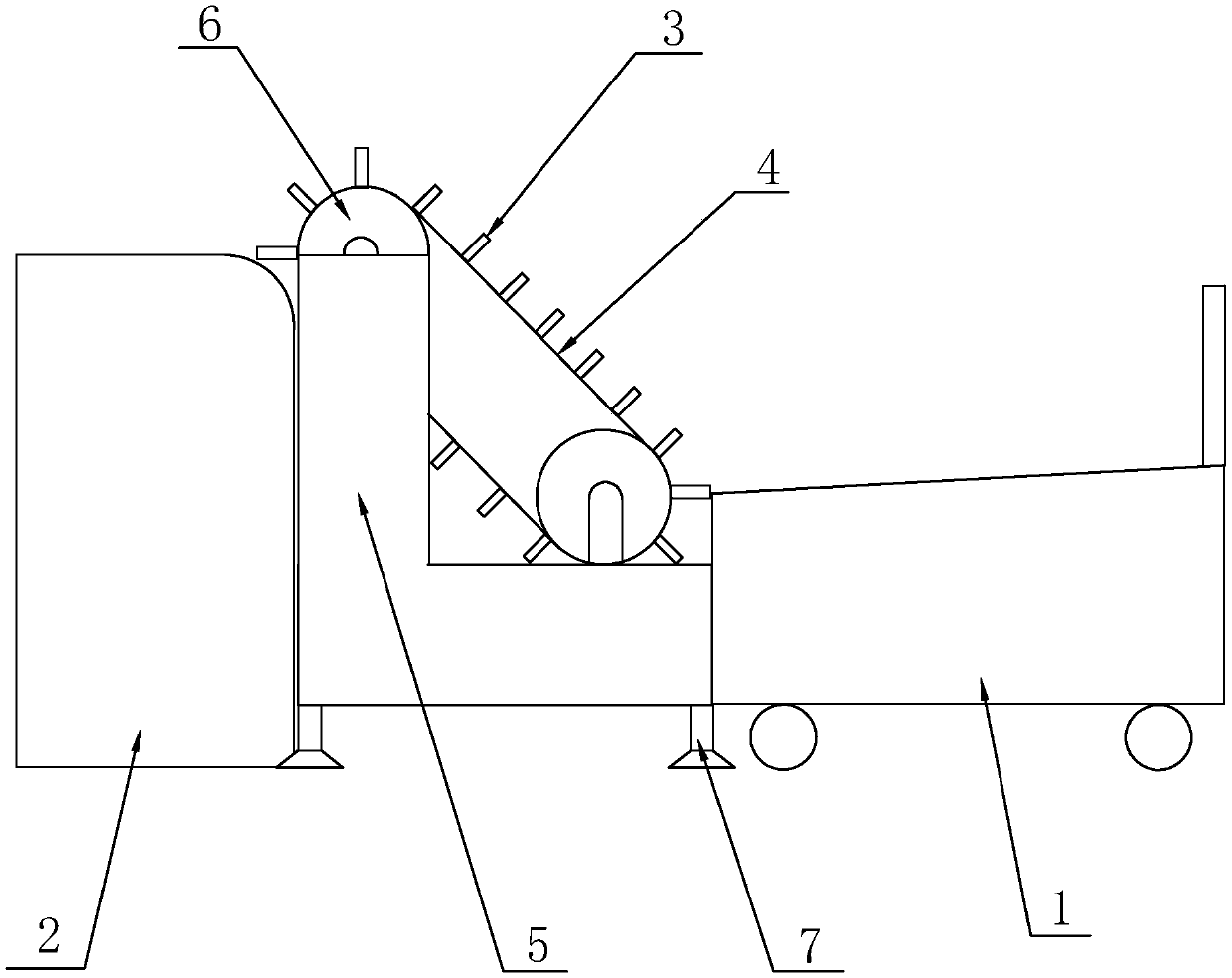

[0017] Such as figure 1 As shown, the present invention provides a light bar transmission device, including a mobile platform 1 and a workbench 2, the height of the workbench 2 is higher than the mobile platform 1, and a conveyor belt 3 is connected between the mobile platform 1 and the workbench 2, and the conveyor belt 3 transports the lights The strips are conveyed from the mobile platform 1 to the worktable 2, the mobile platform 1 is inclined downward at a certain angle to the conveyor belt 3, the transmission belt is arranged obliquely between the mobile platform 1 and the worktable 2, and the conveyor belt 3 is equipped with a plurality of matching light strips for filling The grooves 4 are arranged on the conveyor belt 3 at equidistant intervals.

[0018] In this embodiment, the mobile platform 1 is a trolley.

[0019] In order to ensure that the light...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com