Discharging device and control method

A control method and cutting technology, applied in packaging, loading/unloading, transportation and packaging, etc., can solve the problem of indigestible cutting volume, etc., and achieve the effect of improving service life, high conveying efficiency, and liberating manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

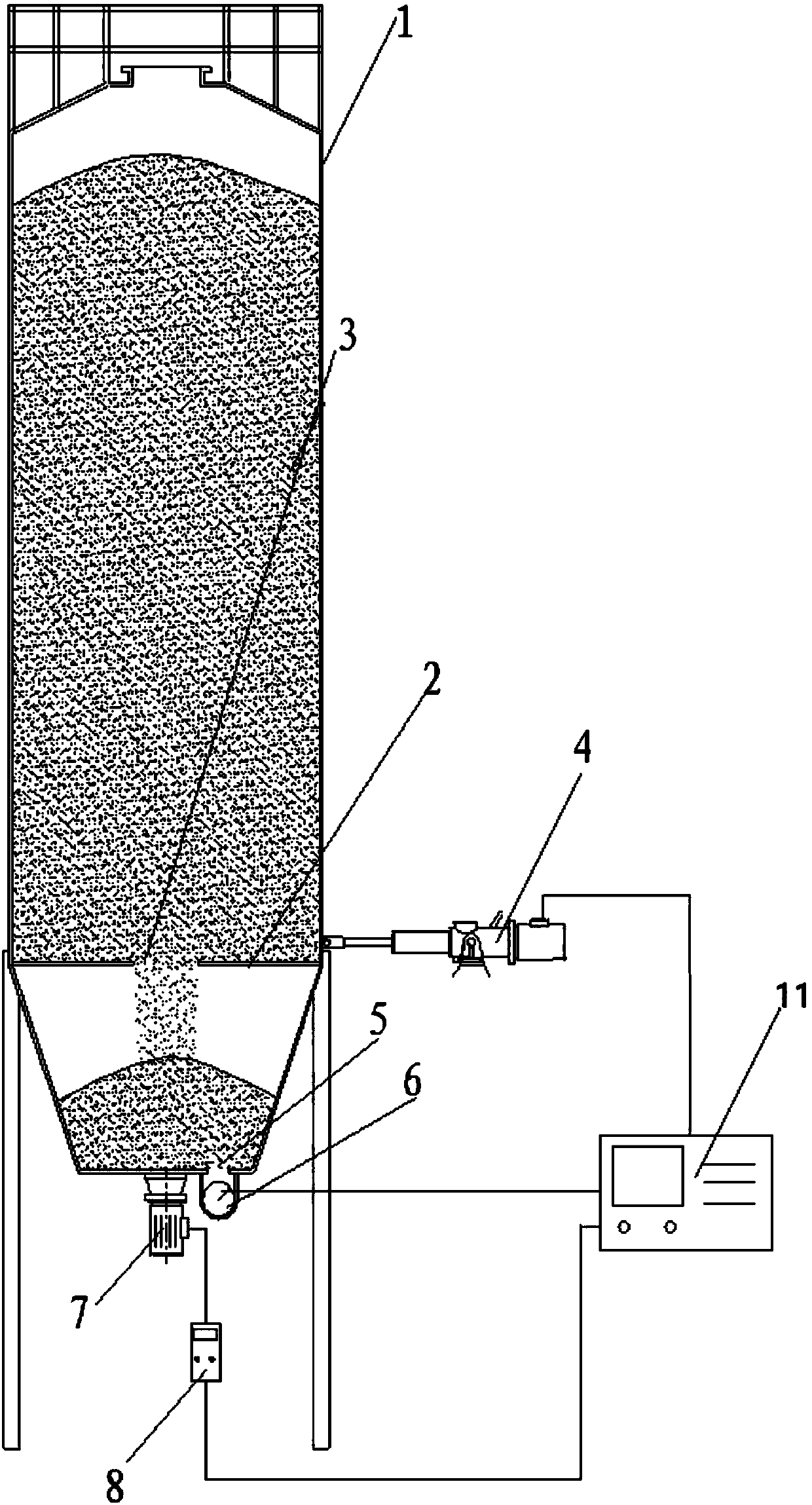

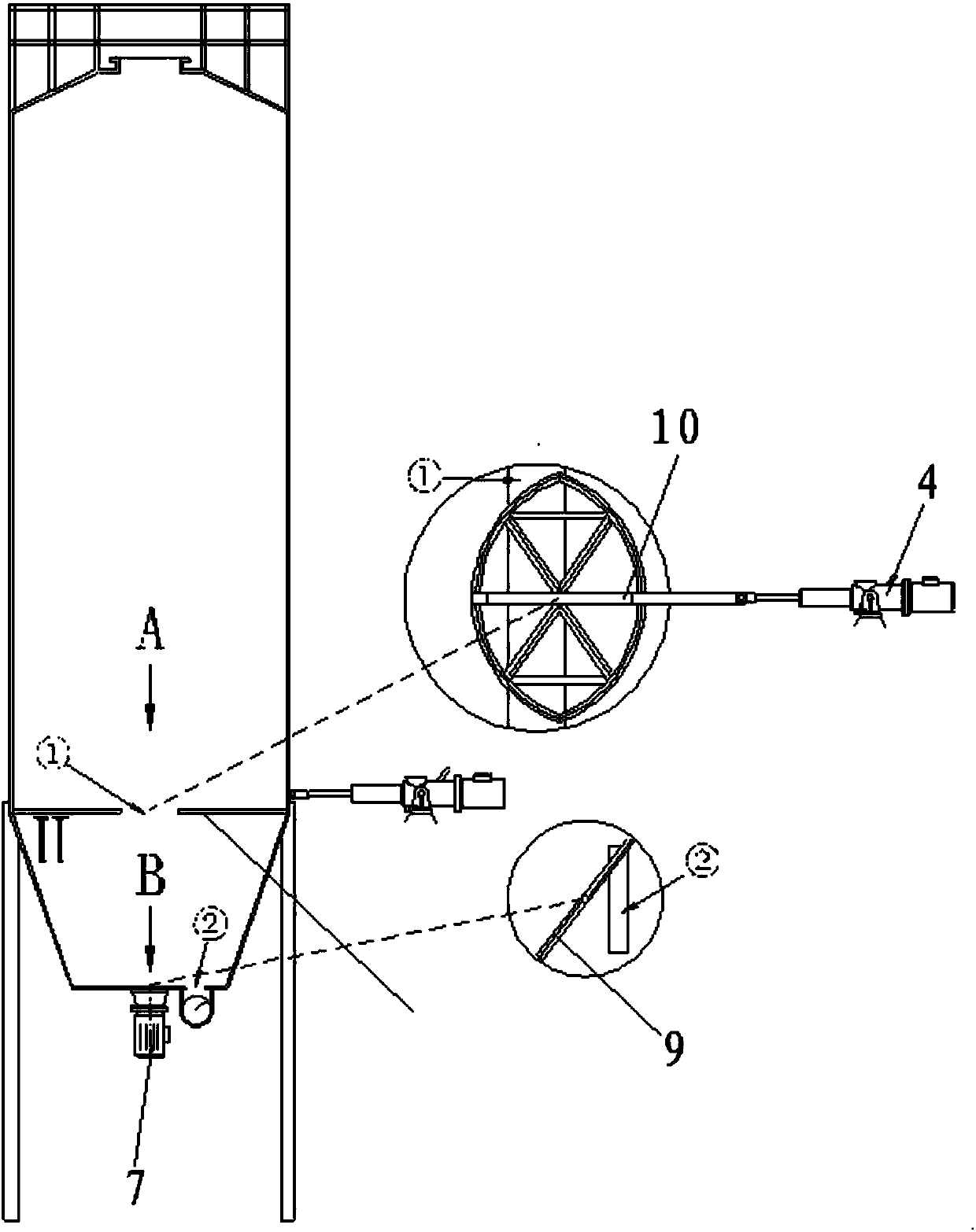

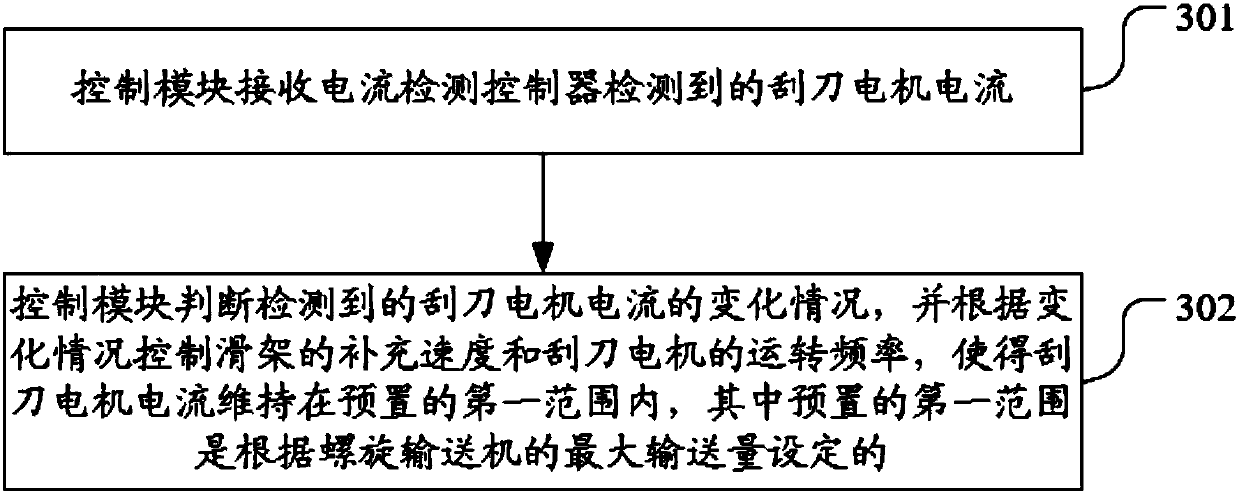

[0042] The embodiment of the present invention provides a material unloading device and a control method. The arch is broken and the material is replenished through the carriage arranged on the load-bearing partition, and the material is scraped to the first unloading gate through the scraper arranged at the bottom of the silo. , and finally transported out by the material conveyor. During the whole process of unloading, the control module controls the supplementary speed of the carriage and the operating frequency of the scraper motor according to the change of the scraper motor current detected by the current detection controller, so that the scraper motor The current is maintained within the preset first range, so that the material replenishment of the carriage does not exceed the maximum conveying capacity of the material conveyor, which solves the problem of arch-breaking and unloading of the existing large-scale silo through a single mechanical unloading device The materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com