Joint connecting working method of a laminated-slab concrete composite precast component

A technology of prefabricated components and concrete, which is applied in the direction of building components, building structures, walls, etc., can solve the problems of difficult binding and difficult to guarantee the connection quality, and achieve the effect of simple binding, simple connection method and guaranteed connection quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

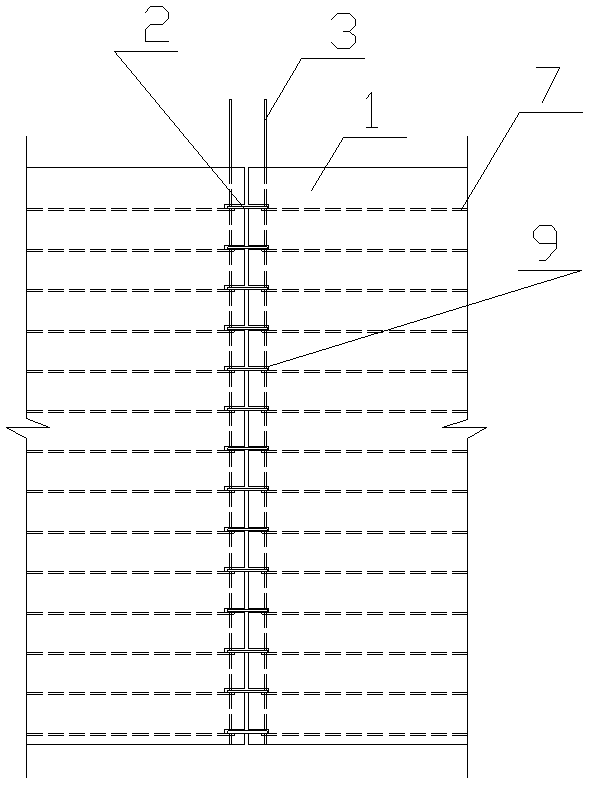

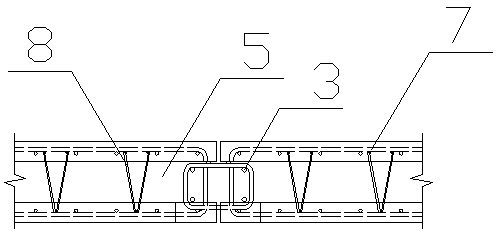

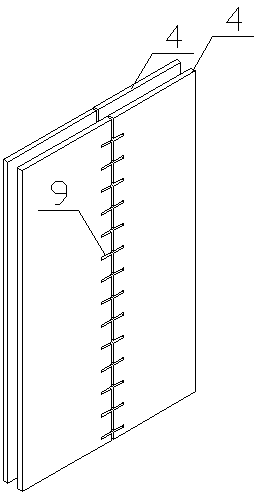

[0026] A superimposed slab type concrete composite prefabricated component connection, which consists of: a superimposed slab concrete prefabricated component 1, the superimposed slab concrete prefabricated component includes two concrete thin slabs 4, and a space is reserved between the two concrete thin slabs Cavity 5, the two concrete thin slabs are connected by truss steel bars 8, the laminated slab-type concrete prefabricated member has vertical steel bars 6 and horizontal steel bars 7, and the single-sided thin slabs of the two concrete thin plates have rectangular gaps 9. A connecting stirrup 2 is placed inside the rectangular gap, and a connecting longitudinal rib 3 is penetrated inside the connecting stirrup.

Embodiment 2

[0028] According to the superimposed slab concrete composite prefabricated component connection described in embodiment 1, the connecting stirrup is ring-shaped, and the ring shape adopts butt welding, 135° hook and 90° hook form, and the connection longitudinal The bars are straight bars, the horizontal bars are closed loops, and the connecting longitudinal bars are located at the corners of the gaps between the connecting stirrups and the horizontal bars.

Embodiment 3

[0030] According to the composite slab-type concrete composite precast member connection described in embodiment 1, the rectangular notches are at the same distance and the same number as the connecting stirrups, and the width of the rectangular notches is 10 larger than the diameter of the connecting stirrups. -30mm, the length of the rectangular notch is 10-30mm larger than the projection length of the concrete precast member at the theoretical connection position of the connecting stirrup, and the thickness of the rectangular notch is the same as the thickness of the single-sided thin slab of the two concrete thin slabs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com