Flow division type jetting and suction hydraulic impactor

A hydraulic impactor and shunt-type technology, which is applied to the driving device for drilling in the borehole, drilling equipment, earthwork drilling and production, etc., can solve the problems of small single impact force and short life of the impactor, and achieve fluid flow resistance Small size, stable working performance and reduced pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

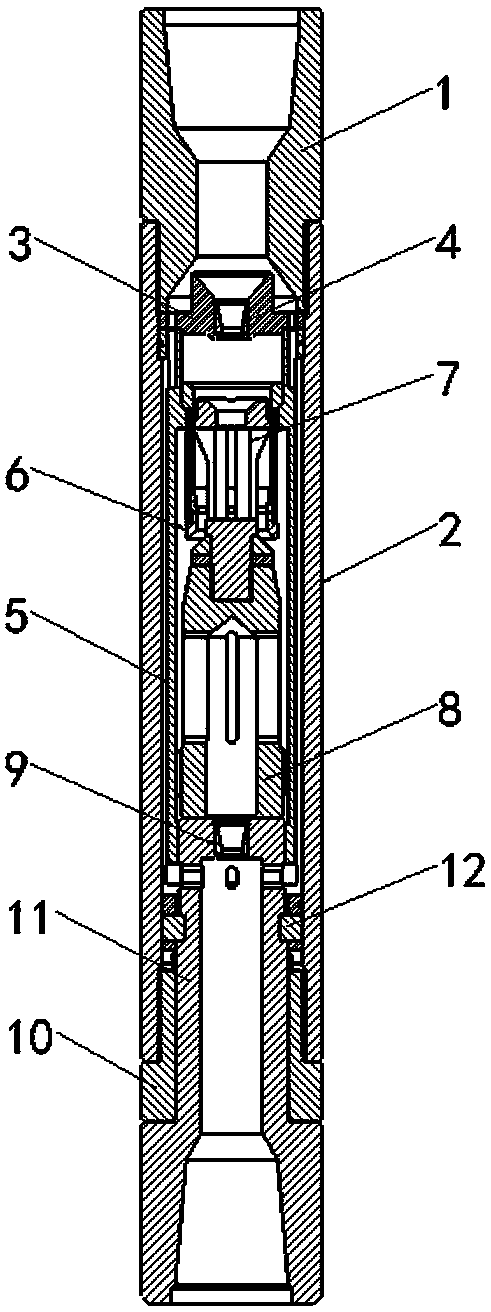

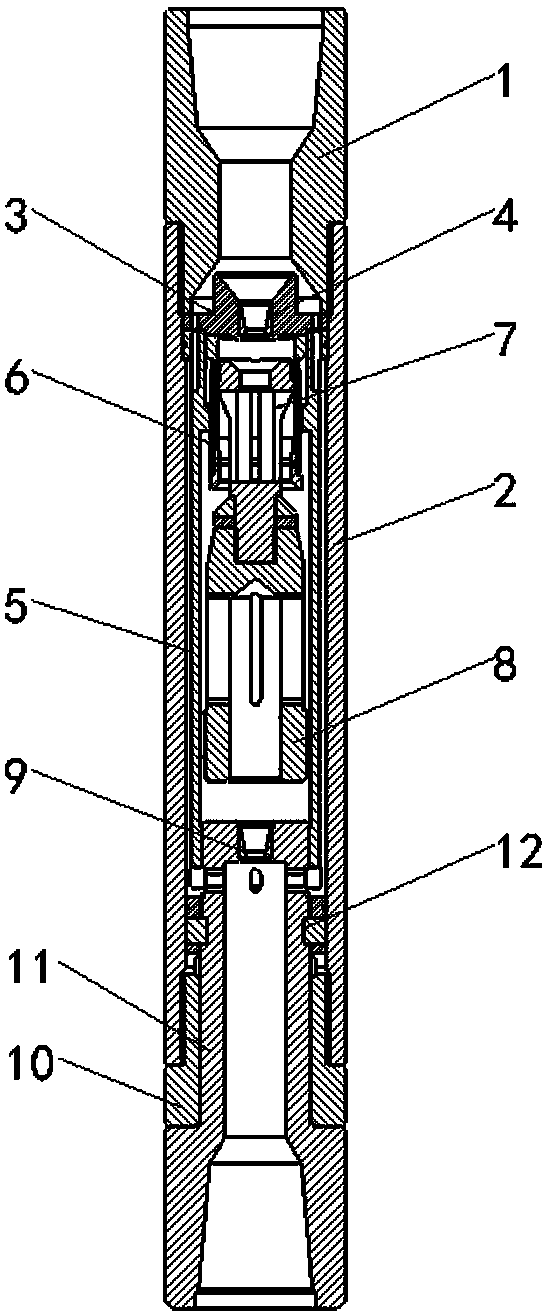

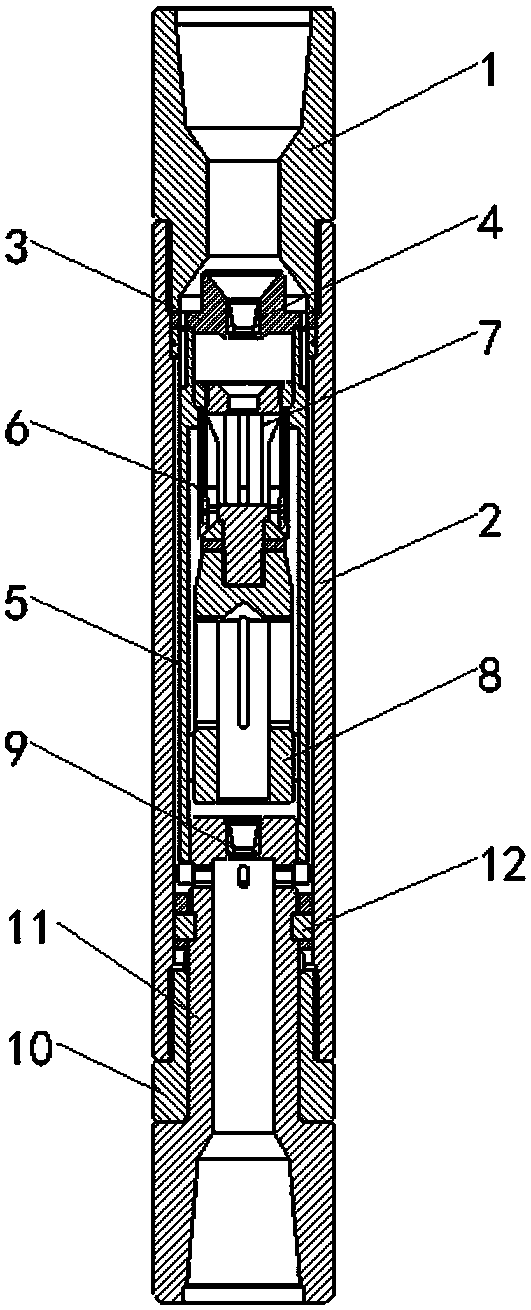

[0021] Below in conjunction with accompanying drawing, the present invention will be further described:

[0022] like figure 1 As shown, the shunt-type injection liquid dynamic impactor includes an upper joint 1, a shell short 2, and a transmission short 11. The upper end of the shell short 2 is connected to the upper joint 1, and the lower end is connected to the transmission short 11. The transmission short 11 has Upper top, transmission short connection 11 The cavity between the upper top and the upper joint 1 is provided with an upper nozzle seat 3, a hammer inner sleeve 5, a valve sleeve 6, and an impact hammer 8. The hammer inner sleeve 5 is a hollow cylinder. There is a ring-shaped step on the upper part of the chamber, and the upper end of the hammer inner sleeve 5 has a screw hole, which is connected with the upper nozzle seat 3 by screws, and the upper nozzle 4 is fixed in the center hole of the upper nozzle seat 3 by a clip spring, which is convenient for replacing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com