Spring safety valve debugging device

A safety valve and valve stem technology, applied in valve device, valve operation/release device, measuring device, etc., can solve the problems of neglecting friction force, poor adjustment accuracy of safety valve setting pressure, large tension, etc., and achieve accurate debugging. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

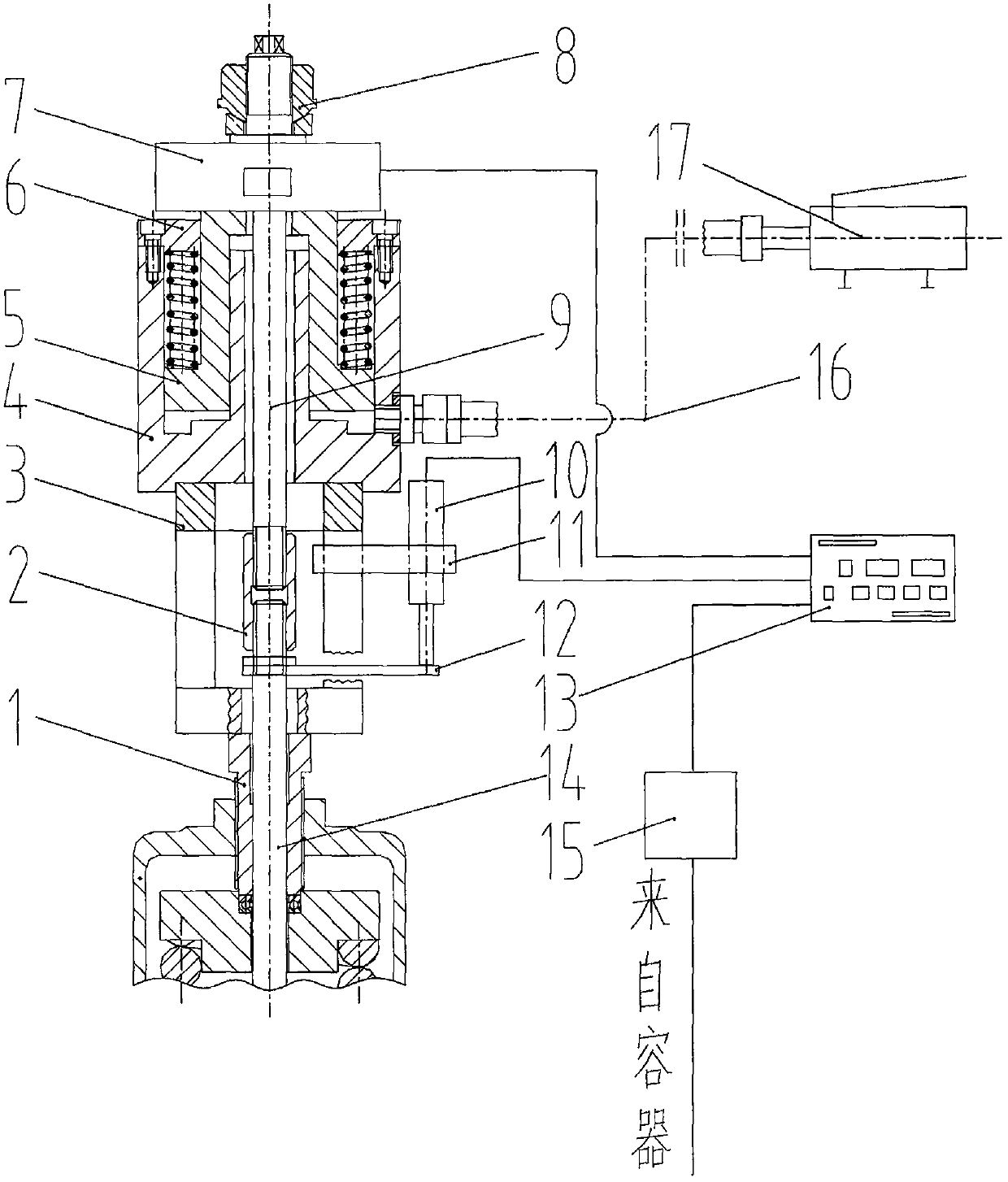

[0010] exist figure 1 In the shown embodiment, the bracket is placed on the adjustment screw of the safety valve, the hydraulic cylinder is placed on the bracket, the load cell is placed on the piston, the valve stem of the safety valve passes through the hydraulic cylinder and is rigidly connected to the pull rod through the connecting nut, and is tightened ten thousand times. Compress the load cell against the nut. When the safety valve is opened, the load cell can accurately measure the pulling force on the valve stem.

[0011] The displacement sensor is fixed on the bracket, and the stroke baffle is rigidly connected with the valve stem of the safety valve. Adjust the position of the displacement sensor so that the sensor is in contact with the stroke baffle to ensure accurate measurement of the actual displacement of the safety valve stem. Whether the safety valve is opened or not is judged by the displacement of the valve stem.

[0012] The pressure transmitter is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com