Two-phase flow efficient refrigeration device

A refrigeration device, high-efficiency technology, applied in refrigerators, refrigeration and liquefaction, lighting and heating equipment, etc., can solve the problems of reduced service life of equipment, limited cooling effect of heating units, hidden safety hazards, etc., to achieve efficient cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

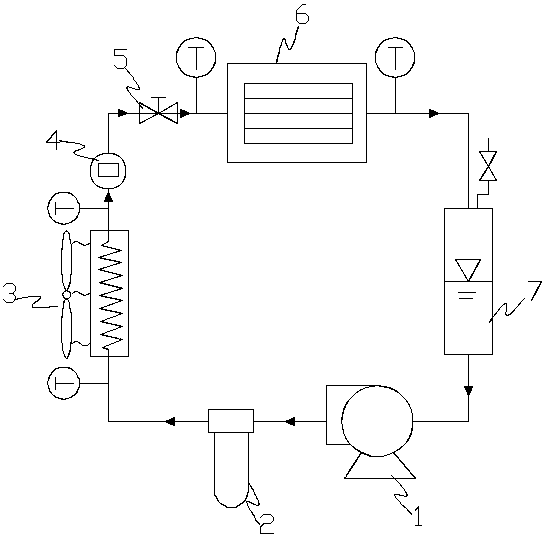

[0012] As shown in the figure, a two-phase flow high-efficiency refrigeration device includes a circulating fluorine pump 1, a filter 2, an air-cooled condenser 3, a flow meter 4, a solenoid valve 5, a microchannel cooler 6, and a liquid reservoir 7 in sequence The refrigeration circuit formed by connecting the ends in series, the refrigerant is HF7100 with a freezing point of 60°C. The channel width of the microchannel cooler is 100-400μm, the channel height is 250-800μm, and the flow rate of the refrigerant entering the microchannel is 45m / s-55m / s. Under this condition, the heat flux density of the cooler reaches 400W / cm2.

[0013] The cooling principle of this refrigeration device is: the fluorinated liquid is transported to the filter 2 by the circulating fluorine pump 1 for filtration, then enters the air-cooled condenser 3 for heat exchange, cools the fluorinated liquid to a supercooled state, and passes through the flow meter 4 Monitor the flow rate of the fluorinated l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com