A conduction-cooled magnet based on rebco superconducting ring

A technology of conduction cooling and superconducting rings, which is applied in the direction of superconducting magnets/coils, magnetic objects, magnetic films to substrates, etc., and can solve the problems of complex cooling systems, lower cooling temperatures, and high costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

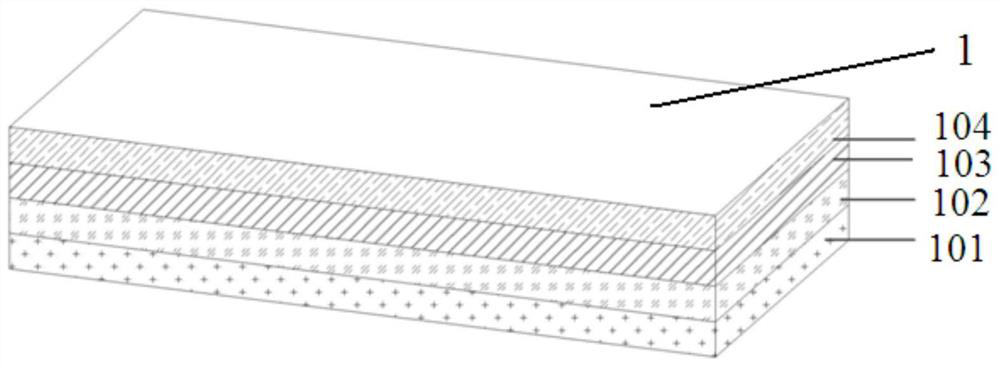

[0042] Prepare as attached figure 1 The specific process of the ReBCO superconducting sheet shown is as follows:

[0043] (1) Using the same substrate material as the second-generation high-temperature superconducting coating to produce a sheet-shaped substrate 101, wherein the substrate material is Ni, NiW, Hastelloy or stainless steel;

[0044] (2) On the substrate 101, a second-generation high-temperature superconducting buffer layer preparation process is used to deposit a buffer layer 102, wherein the buffer layer is an insulating metal oxide;

[0045] (3) On the buffer layer 102, a ReBCO thin film 103 is plated on the second generation high temperature superconducting thin film coating technology;

[0046] (4) Plating a protective layer 104 on the ReBCO thin film 103 , wherein the protective layer 104 is a silver thin film protective layer or a copper thin film protective layer, that is, the ReBCO superconducting thin sheet 1 is obtained.

[0047] The preparation proce...

Embodiment 2

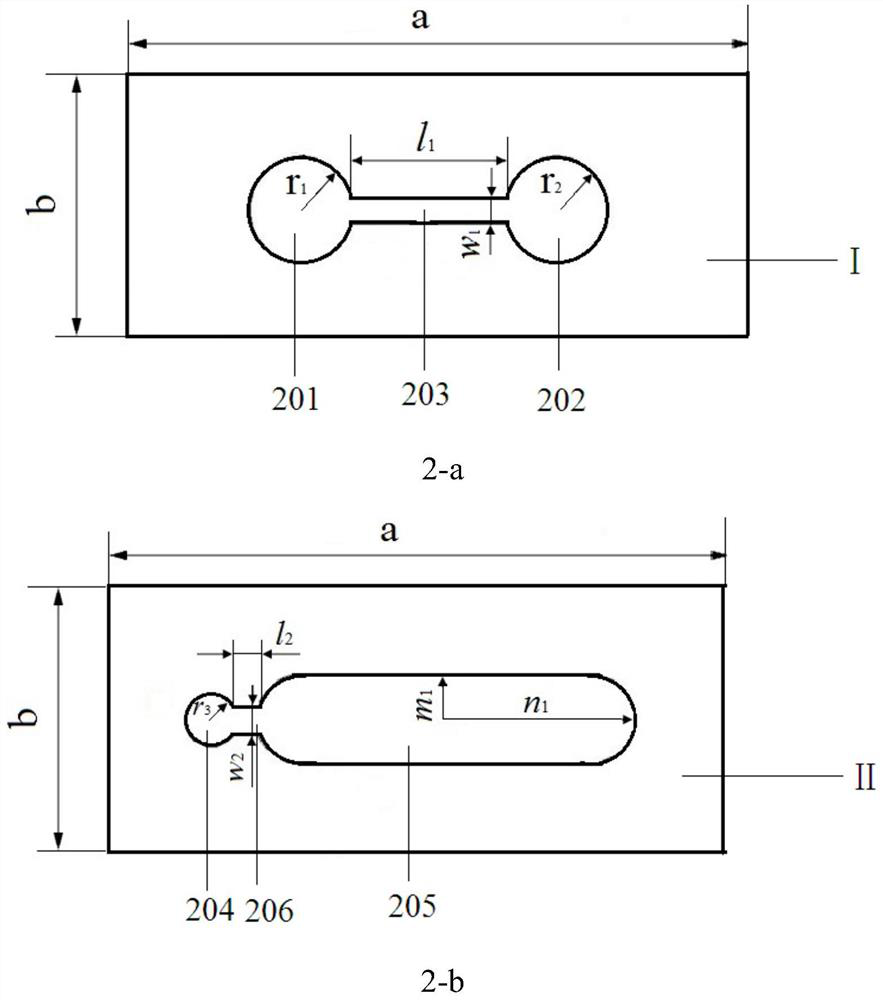

[0049] prepared as figure 2 The specific process of the shown ReBCO superconducting ring is as follows:

[0050] in, figure 2 The specific preparation process of the ReBCO square superconducting ring piece Ⅰ shown in -a is cut with two circular holes located apart from each other:

[0051] Cut the ReBCO superconducting sheet obtained in Example 1 into a square sheet with a length of a and a width of b, and then cut out a position with a radius of r at the preferred central position inside the square sheet 1 The first circular hole 201 and the radius r 2 The second round hole 202 of the first round hole 202, and at the same time cut out a width w 1 , with length l 1 The first slit 203 of the first, in order to communicate with the first round hole 201 and the second round hole 202, that is, as figure 2 ReBCO square superconducting ring piece Ⅰ shown in -a.

[0052] in, figure 2 The specific preparation process of the ReBCO square superconducting ring chip II shown in...

Embodiment 3

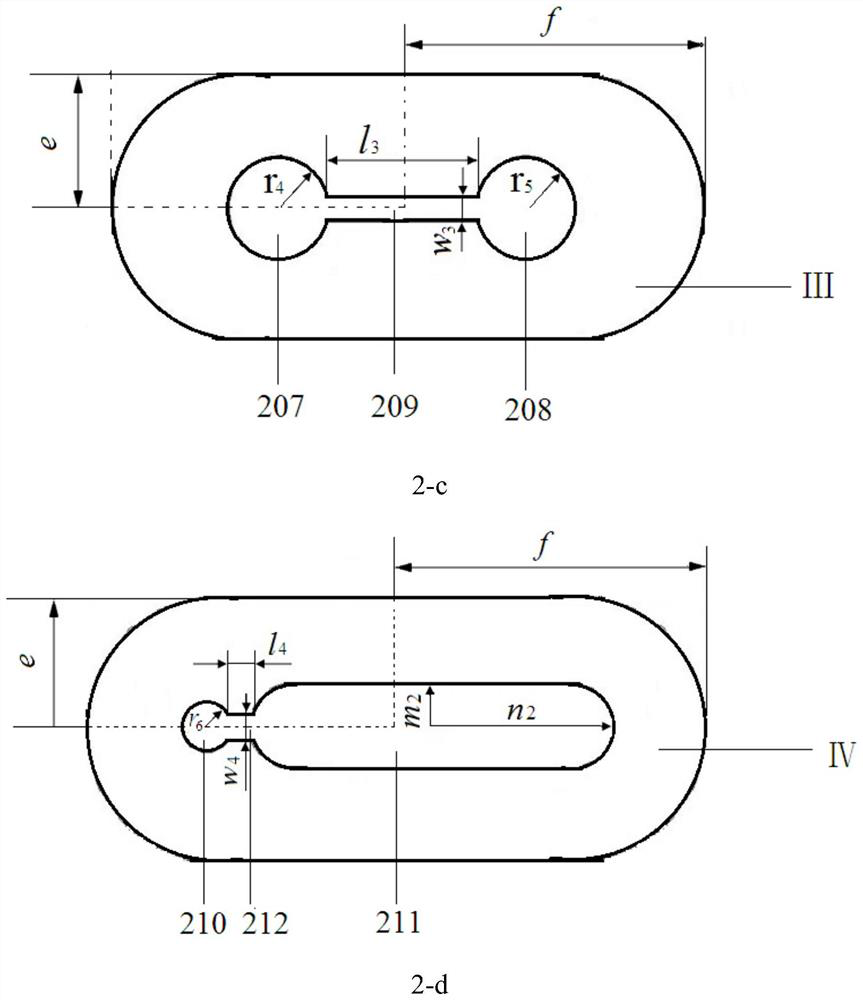

[0060] prepared as image 3 Insulation sheet as shown: cut an organic insulation film such as PPLP insulation film, kraft paper or epoxy sheet into an insulation sheet with the same shape and size as the superconducting ring sheet shown in Example 2.

[0061] in, image 3 -a is with figure 2 - ReBCO square superconducting ring piece Ⅰ shown in -a and square insulation piece Ⅴ with the same shape and size; image 3 -b for the same figure 2 The ReBCO square superconducting ring piece II shown in -b has the same shape and size as the square insulating piece VI; image 3 -c for the same figure 2 The shape and size of the ReBCO racetrack-shaped superconducting ring piece III shown in -c are exactly the same as the racetrack-shaped insulating piece VII; image 3 -d for the same figure 2 The ReBCO racetrack-shaped superconducting ring sheet IV shown in -d has the same shape and size as the racetrack-shaped insulating sheet VIII.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com