Dehumidifying and drying device for flue-cured tobacco

A drying device and flue-cured tobacco technology, applied in drying, drying machine, tobacco drying and other directions, can solve the problems of not being able to supply heat for a long time, failing to meet emission reduction standards, affecting the quality of baking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

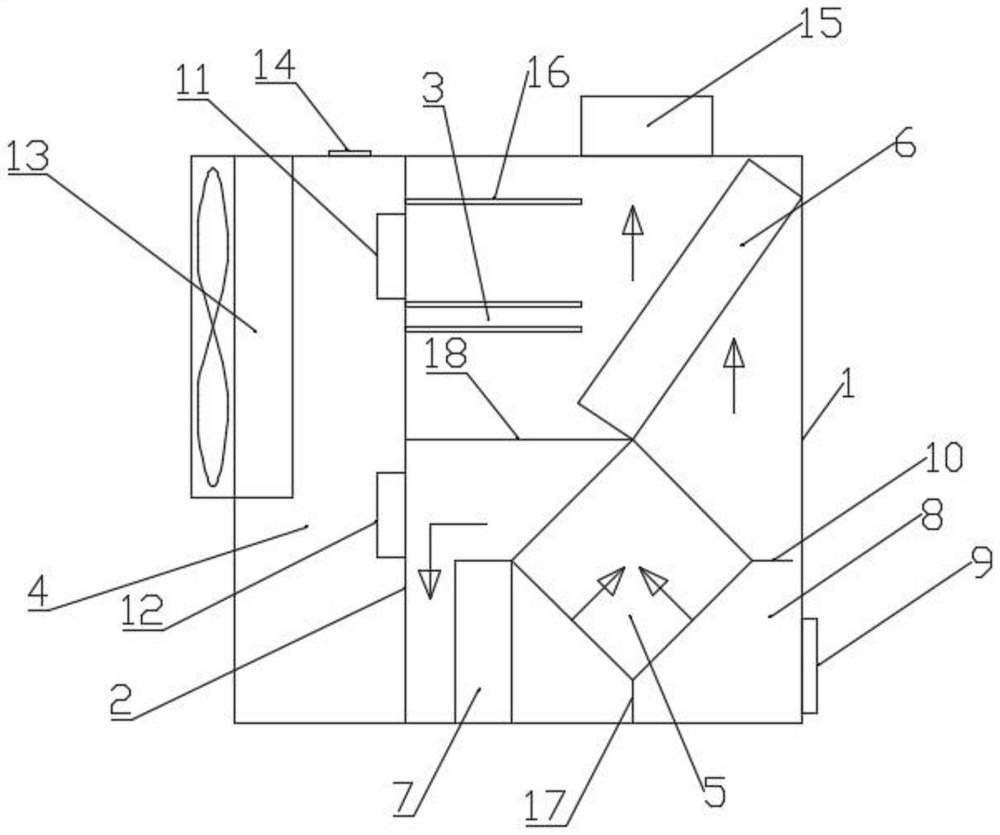

[0026] The following position and orientation descriptions are based on figure 1 The description of the distribution does not constitute a limitation.

[0027] Such as figure 1 As shown, a dehumidification and drying device for flue-cured tobacco includes a housing 1, and a first partition is arranged inside the housing 1 to divide it into a first space 3 on the right side and a second space 4 on the left side. 2. An air-to-air heat exchanger 5 is installed near the lower end of the first space 3, and the air-to-air heat exchanger 5 is set at an angle of 45° to the horizontal plane so that the heat exchange channel is inclined at 45°. The upper end of the gas-air heat exchanger 5 in the first space 3 is connected to the lower end of the condenser 6 and the upper end of the dehumidification evaporator 7 in a contact-sealed manner, respectively. A second partition 18 is arranged between the connection between the air-to-air heat exchanger 5 and the condenser 6 and the first pa...

Embodiment 2

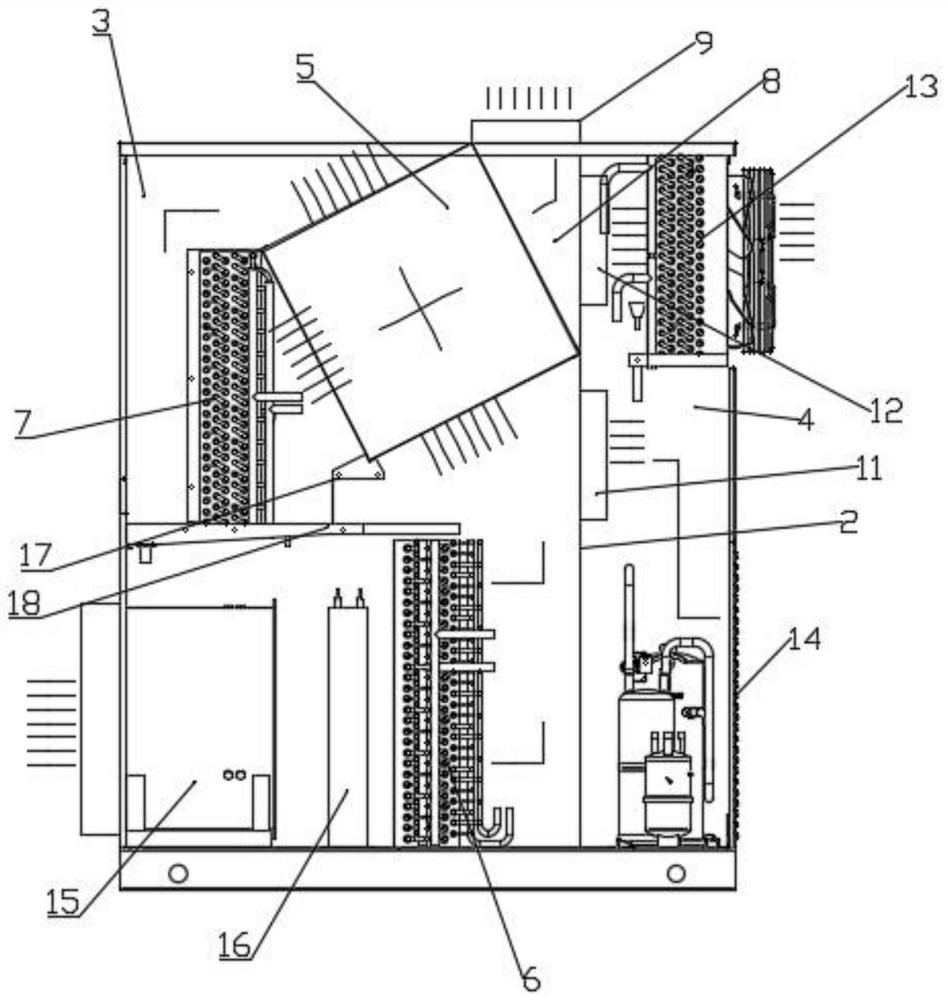

[0033] The following position and orientation descriptions are based on figure 1 The description of the distribution does not constitute a limitation.

[0034] Such as figure 2As shown, a dehumidification and drying device for flue-cured tobacco includes a housing 1, and a first partition is arranged inside the housing 1 to divide it into a first space 3 on the right side and a second space 4 on the left side. 2. The upper end of the first space 3 is provided with an air-to-air heat exchanger 5, and the air-to-air heat exchanger 5 is set at an angle of 45° to the horizontal plane so that the heat exchange channel is inclined at 45°. The upper left angle end and the right angle end of the air-to-air heat exchanger 5 in the first space 3 are respectively contact-sealed and connected to the upper end of the dehumidification evaporator 7 and the first partition 2. On the side wall, the housing 1 and the second partition 18 corresponding to the third space 8 formed between the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com