Treatment method of high-salt and high-COD wastewater

A treatment method and wastewater technology, applied in water/sewage treatment, multi-stage water/sewage treatment, neutralized water/sewage treatment, etc., can solve problems such as pollution and high energy consumption, and achieve reduced economic investment and low energy consumption , to ensure the effect of repeated use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

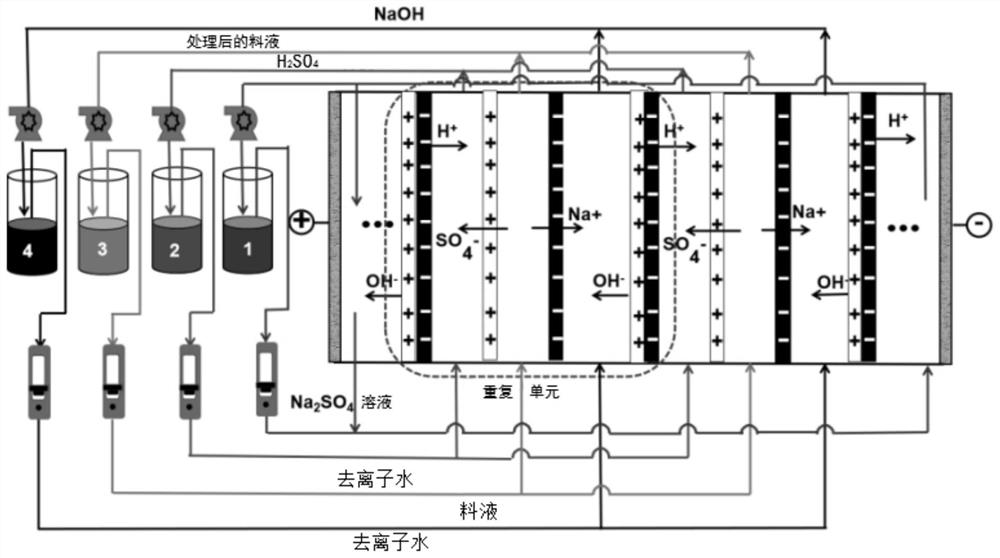

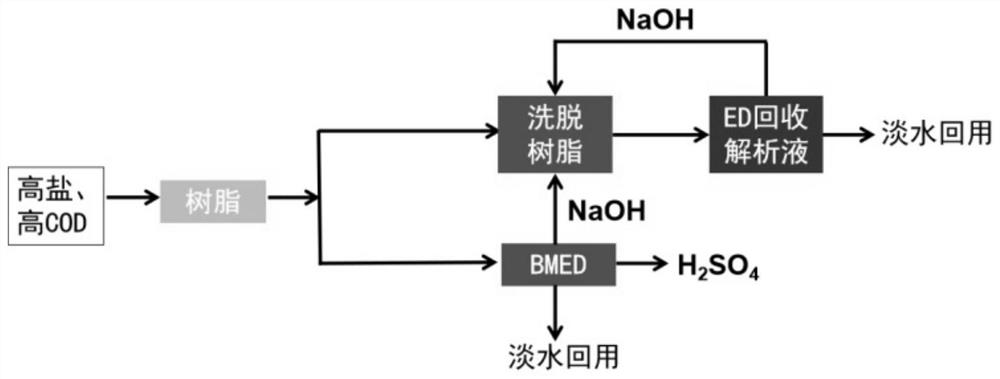

[0025] In the embodiment of the present invention, a method for treating high-salt and high-COD wastewater to recover acid and alkali, the wastewater is high-salt aniline-containing wastewater that has been pretreated with sulfuric acid to neutrality, wherein the concentration of sodium sulfate is about 3%, and the concentration of COD is about 1500ppm, the specific steps are as follows:

[0026] Resin adsorption: A-722MP is selected as the resin for removing organic matter in high-salt and high-COD wastewater. Add 100g resin to the adsorption column, control the speed of waste water flowing through the adsorption column at 5BV / h, and control the COD of the resin effluent within 50ppm. Samples were taken every 10 minutes to detect the COD content of the resin effluent. In 100 minutes, that is, when the effluent volume was 150BV, the COD content remained basically the same as that in the original solution, and the adsorption effect was not obvious. LS-109D is the resin choice ...

Embodiment 2

[0028] In the embodiment of the present invention, a method for treating high-salt and high-COD wastewater to recover acid and alkali, the wastewater is high-salt aniline-containing wastewater that has been pretreated with sulfuric acid to neutrality, wherein the concentration of sodium sulfate is about 3%, and the concentration of COD is about 1500ppm, the specific steps are as follows:

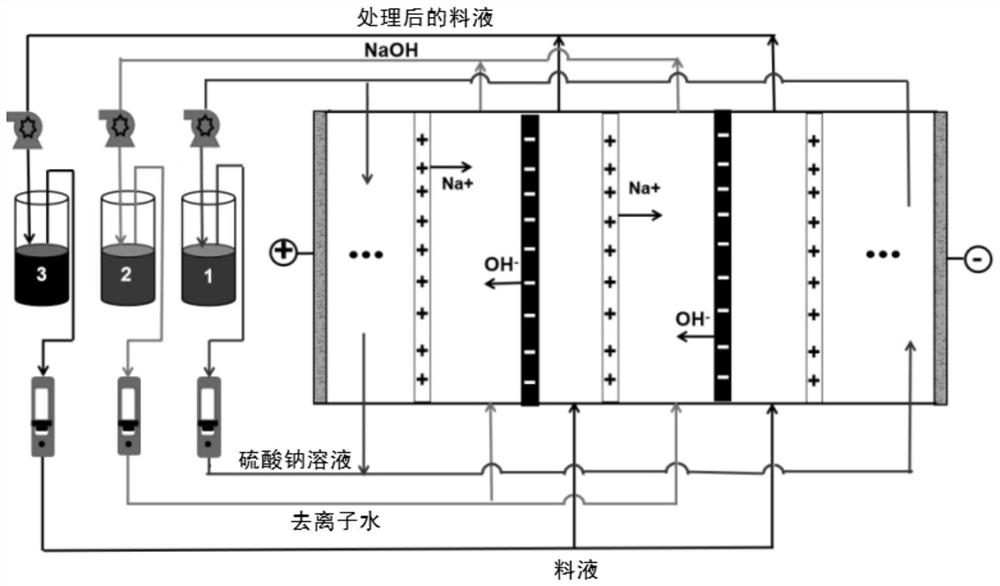

[0029]Resin adsorption: LS-109D is the resin choice for organic matter in high-salt and high-COD wastewater. Add 100g resin to the adsorption column, control the speed of waste water flowing through the adsorption column at 5BV / h, and control the COD of the resin effluent within 50ppm. Samples were taken every 10 minutes to detect the COD content of the resin effluent. In 100 minutes, the COD content was 48.19ppm when the effluent volume was 150BV, and the adsorption effect was obvious. Therefore, the adsorption time was controlled to be 100 min.

[0030] Preparation of acid and base by tw...

Embodiment 3

[0036] In the embodiment of the present invention, a method for treating high-salt and high-COD wastewater to recover acid and alkali, the wastewater is high-salt aniline-containing wastewater that has been pretreated with sulfuric acid to neutrality, wherein the concentration of sodium sulfate is about 3%, and the concentration of COD is about 1500ppm, the specific steps are as follows:

[0037] Resin adsorption: LS-109D is selected as the resin for removing organic matter in high-salt and high-COD wastewater. 100g of resin was added to the adsorption column, the speed of wastewater flowing through the adsorption column was controlled at 5BV / h, the adsorption time was 100min, and the COD content of the resin effluent was 48.19ppm.

[0038] Acid-base preparation by bipolar membrane electrodialysis: collect resin effluent and pass it into bipolar membrane electrodialysis device. The bipolar membrane electrodialysis device is the same as that in Example 1, which is composed of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com