Performance testing method for broken stone sealing layer and asphalt amount determination method

A technology of gravel sealing layer and asphalt dosage, which is applied in the direction of using material absorption and weighing, can solve the problems of large sealing layer production area, low universal applicability, high production difficulty, etc., and achieves simple and fast test process and simple test method , to achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

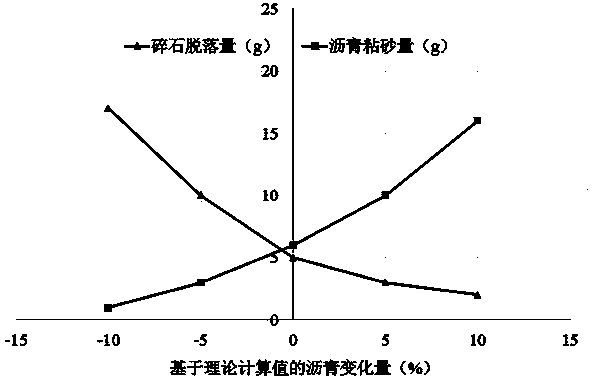

[0028] Aiming at the deficiencies of the prior art, the idea of the present invention is to quantitatively characterize the asphalt of the gravel seal layer by using the amount of fine sand attached to the sample under certain conditions after the rutting test by using a smaller-sized test sample. The degree of oil bleed, and further characterize the durability of the gravel seal by the amount of gravel shedding of the sample after the rutting test; finally, according to the test results of the degree of asphalt oil bleed and the durability of a group of gravel seals with different amounts of asphalt As a result, the optimal asphalt dosage for the chip seal was determined.

[0029] Specifically, the performance testing method of the gravel seal of the present invention comprises the following steps:

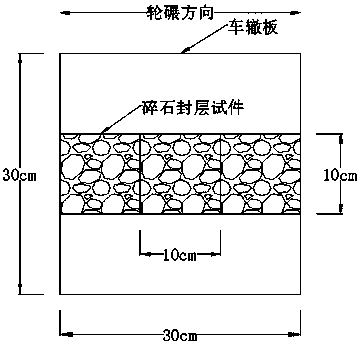

[0030] Step A, complete the production of the sam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com