Corrosion detection method for concrete sewage pipe

A corrosion detection and concrete technology, applied in weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve problems such as low mechanical strength, easy corrosion, large uncertainty, etc., to improve accuracy and standardization , the reaction area is convenient, and the quantity is flexible and variable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below through specific embodiments and accompanying drawings. The embodiments of the present invention are for better understanding of the present invention by those skilled in the art, and do not limit the present invention in any way.

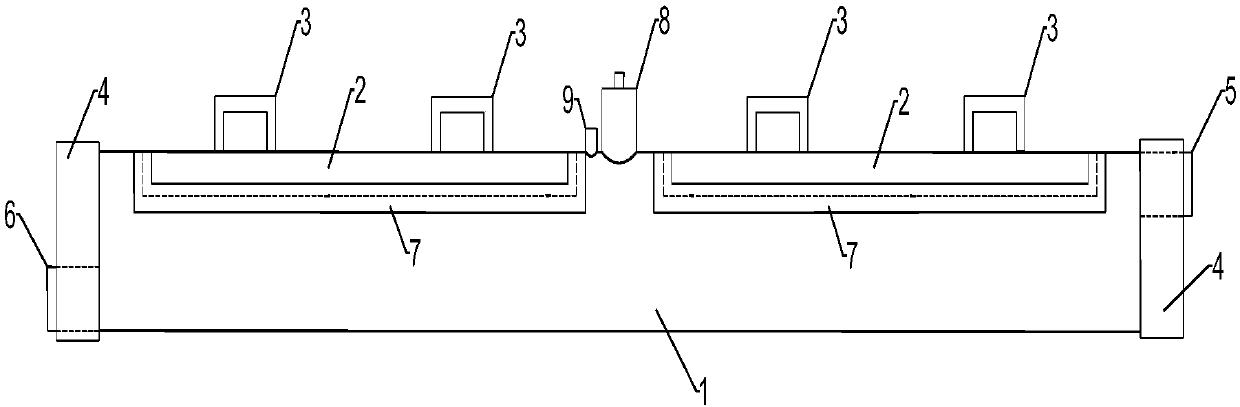

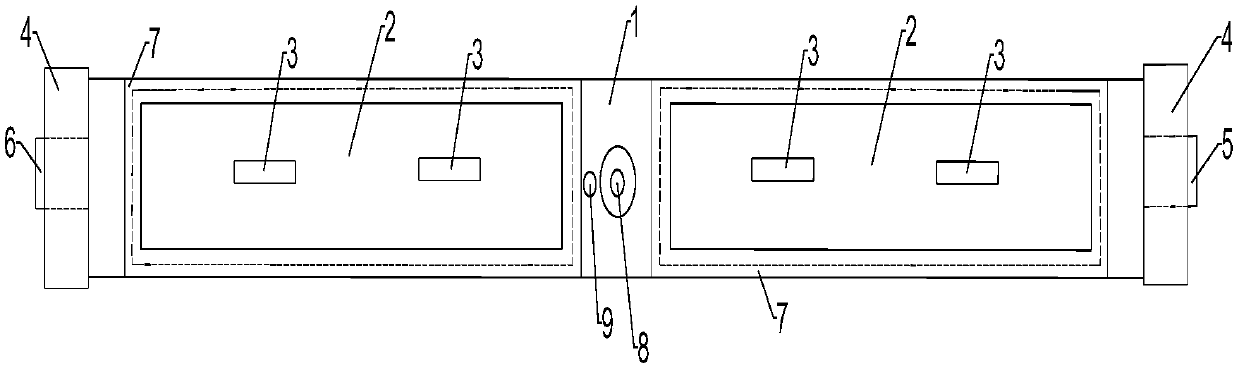

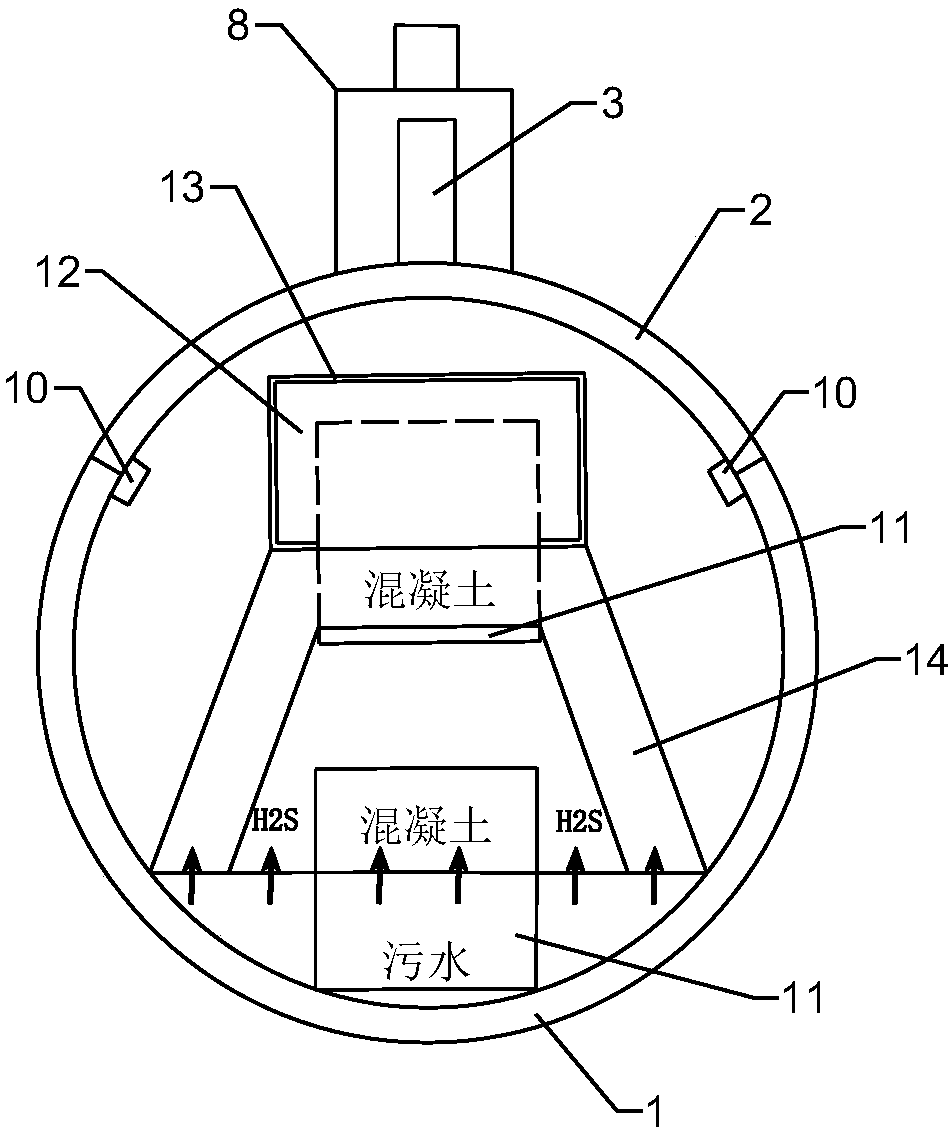

[0033] The technical solution of the present invention is a method for detecting corrosion of concrete sewage pipes, using simulated pipeline devices such as figure 1 , 2 Shown in and 3, the method steps are as follows:

[0034] First select the reference plane to determine the thickness change of the concrete test block before and after corrosion: select the plane where the epoxy resin upper surface and the stainless steel frame on both sides are located; secondly, before the corrosion starts, place the concrete test block on the coordinate plane matched with Photogrammetry imaging technology In the process, take photos from the five set directions; then, inject sewage into the main ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com