Microcrystalline-structure metal phosphate and preparation method thereof

A technology of metal phosphate and microcrystalline structure, which is applied in structural parts, electrical components, battery electrodes, etc., can solve the problem of destroying the crystal structure of lithium iron phosphate olivine, reducing compaction density, battery energy density, and the impact of cycle life of multiples, etc. problems, to achieve good rate cycle life, reasonable tap density, and high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0044] This application describes preferred implementation modes and examples, and those skilled in the art can make appropriate changes to the implementation modes and examples described in this application on the basis of reading this application. This application therefore includes all equivalent modifications and variations of the subject matter recited in the claims of this application within the scope permitted by law.

Embodiment

[0046] The present invention is described in detail below with reference to Examples and drawings. Those skilled in the art can understand that the following examples are for the purpose of illustration and should not be construed as limiting the present invention in any way. The protection scope of the present invention is defined by the appended claims.

Embodiment 1

[0051] Add 2 L of 0.5 mol / L ferric nitrate solution into water, add 1 L of 1.8 mol / L orthophosphoric acid solution under stirring condition, continue to heat and stir at 70°C, add ammonia water as a pH value regulator, and control the pH value within the range of 2.0-2.2 , fully reacted to form polycrystalline iron phosphate precipitates; filtered, fully washed and dried to obtain polycrystalline iron phosphate powders, and the iron phosphate polycrystalline powders were calcined in air at 200°C for 60 minutes; after calcined Rapidly cool the above powder to below 80°C in air at a cooling rate of 5°C / min to obtain FePO with a microcrystalline structure 4 .2H 2 O powder.

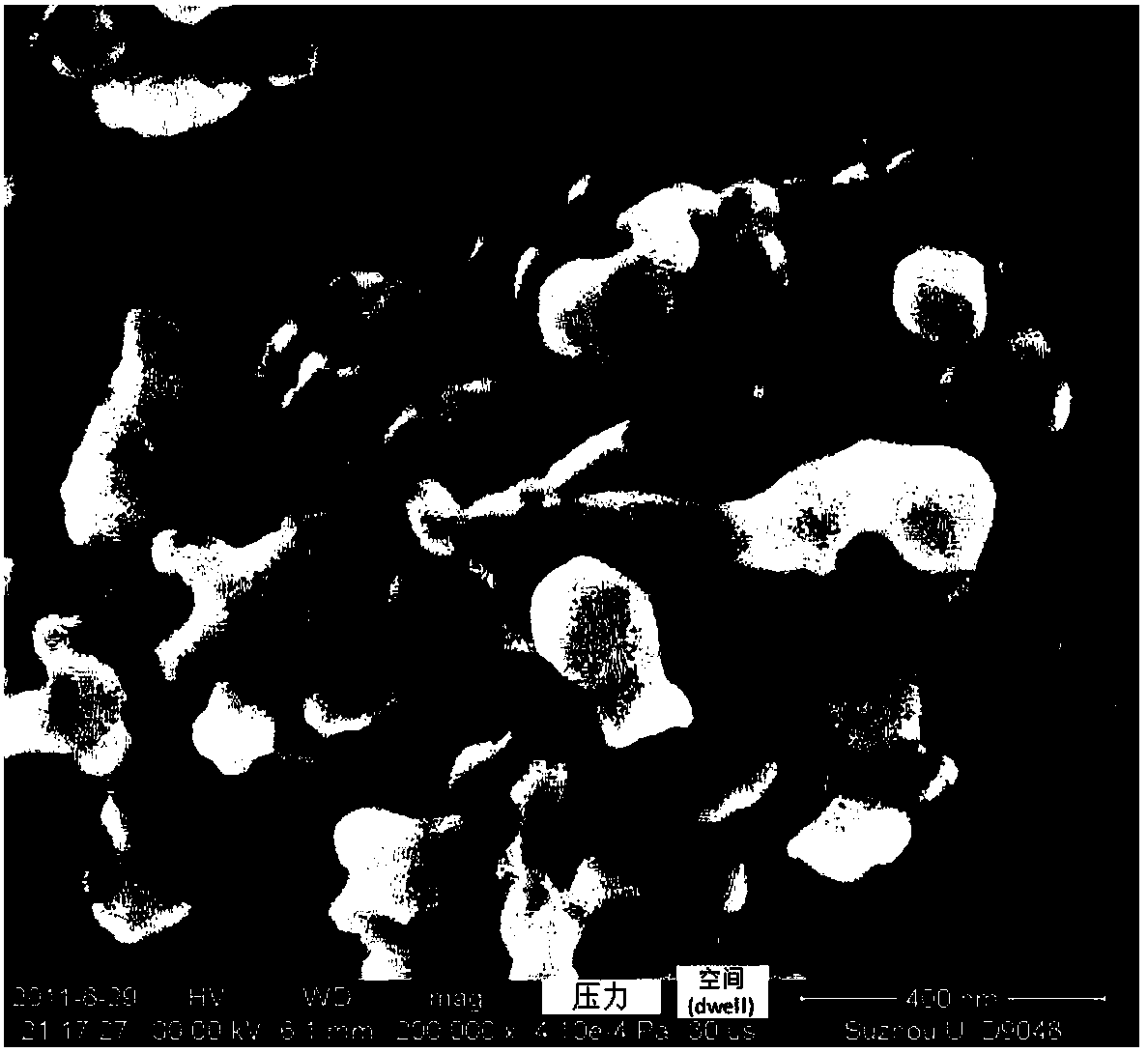

[0052] figure 1 In the scanning electron microscope image showing the microcrystalline ferric orthophosphate of Example 1, the polycrystalline ferric phosphate powder prepared by chemical precipitation, after a lower sintering temperature, initially forms a microcrystalline phosphate powder, and the grain s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap