DC power system

A technology of DC power supply system and DC power distribution, applied in the field of power supply, can solve the problems that the total harmonic distortion can only reach 25%, reduce the power factor, input current waveform distortion, etc., so as to avoid the increase of circulating energy and avoid Loss issues, the effect of reducing harmonics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

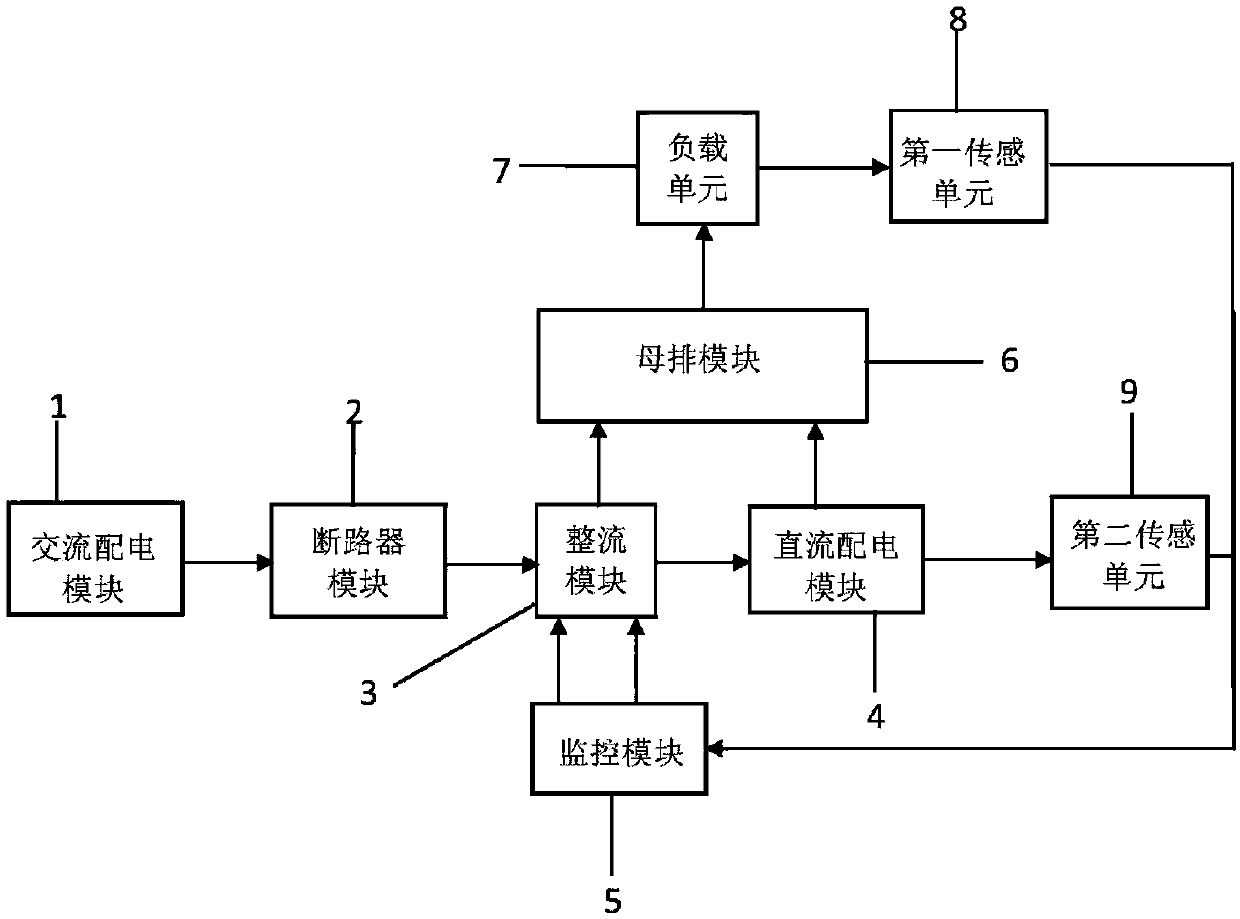

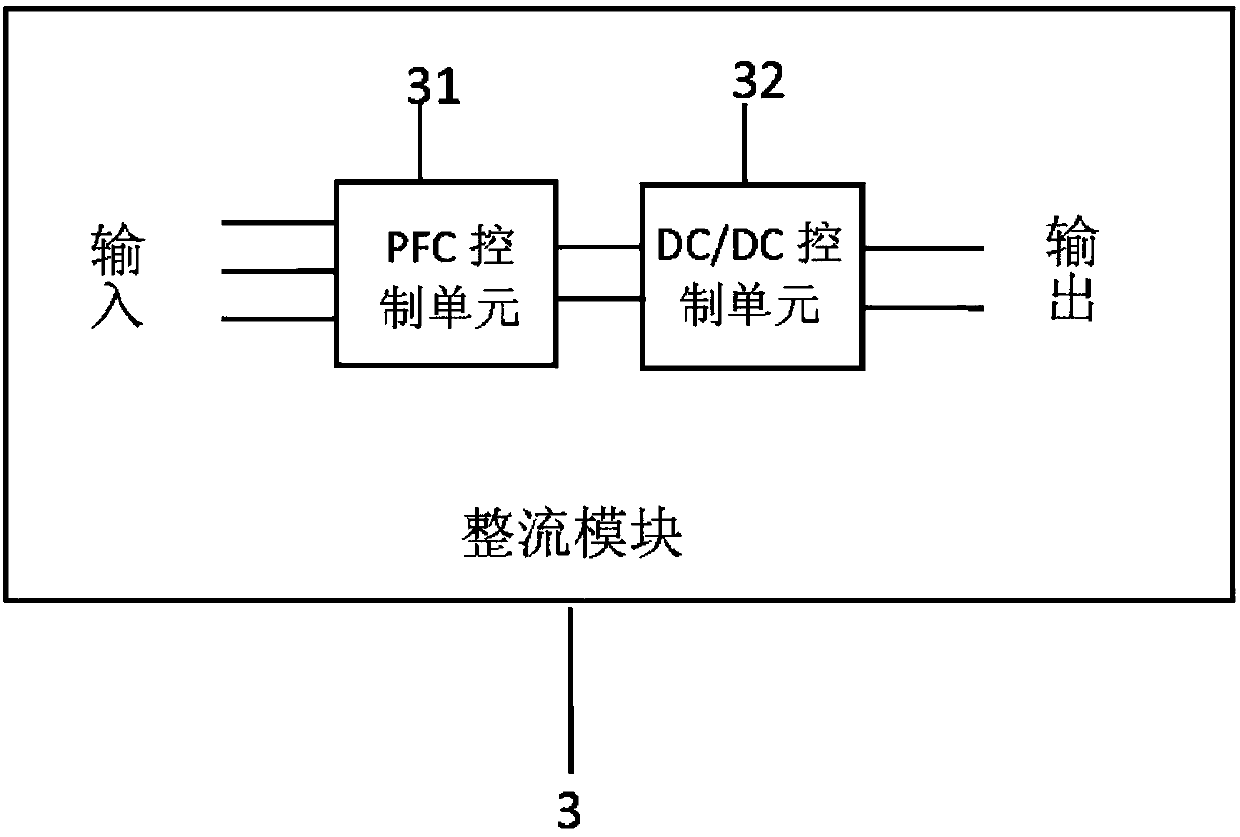

[0018] In the DC power supply system proposed by the present invention, the input end of the AC power distribution module 1 is connected to the AC power supply, the output end of the AC power distribution module 1 is connected to the input end of the circuit breaker module 2, and the output end of the circuit breaker module 2 is connected to two rectifier The input end of the module 3 is connected, the two rectification modules 3 are connected in parallel, the output ends of the two rectification modules 3 are connected to the input end of the busbar module 6, the output end of the busbar module 6 is connected to the input end of the load unit 7, and the load unit The output terminal of 7 is connected to the input terminal of the first sensing unit 8, the output terminal of the first sensing unit 8 is connected to the input terminal of the monitoring module 5, and the output terminals of the two rectification modules 3 are also connected to the input terminal of a DC power distr...

Embodiment 2

[0020] In the DC power supply system proposed by the present invention, the input end of the AC power distribution module 1 is connected to the AC power supply, the output end of the AC power distribution module 1 is connected to the input end of the circuit breaker module 2, and the output end of the circuit breaker module 2 is connected to nine rectifier The input end of the module 3 is connected, the nine rectification modules 3 are connected in parallel, the output ends of the nine rectification modules 3 are connected to the input end of the busbar module 6, the output end of the busbar module 6 is connected to the input end of the load unit 7, and the load unit The output end of 7 is connected to the input end of the first sensing unit 8, the output end of the first sensing unit 8 is connected to the input end of the monitoring module 5, and the output ends of the nine rectification modules 3 are also connected to the two DC power distribution modules 4 The input terminal...

Embodiment 3

[0022] In the DC power supply system proposed by the present invention, the input end of the AC power distribution module 1 is connected to the AC power supply, the output end of the AC power distribution module 1 is connected to the input end of the circuit breaker module 2, and the output end of the circuit breaker module 2 is connected to fifteen The input terminals of the rectifier modules 3 are connected, fifteen rectifier modules 3 are connected in parallel, the output terminals of the fifteen rectifier modules 3 are connected to the input terminals of the busbar module 6, and the output terminals of the busbar module 6 are connected to the input terminals of the load unit 7 , the output end of the load unit 7 is connected to the input end of the first sensing unit 8, the output end of the first sensing unit 8 is connected to the input end of the monitoring module 5, and the output ends of the fifteen rectification modules 3 are also connected to two DC distributions The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com