Energy-saving control system for heating device

An energy-saving control system and heating device technology, applied in electric heating devices, electrical components, multi-phase network asymmetry reduction and other directions, can solve the problems of three-phase load unbalance, low power factor, etc. The effect of power factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

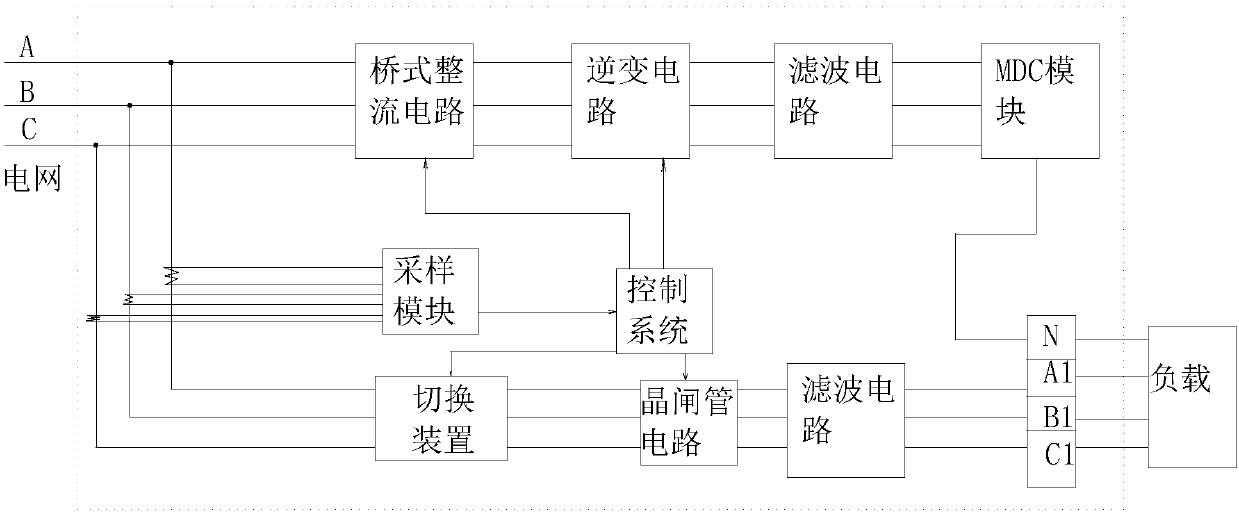

[0023] Example: see figure 1 .

[0024] An energy-saving control system for a heating device, which includes: a sampling module, a switching device, and a control system, wherein the sampling module is used to collect voltage signals and current signals output by three-phase electricity; the switching device is used to switch the external output of three-phase electricity The control system receives the voltage and current signals collected by the sampling module, and controls the switching device to work according to the voltage and current signals, so that the load of the output three-phase electricity is balanced.

[0025] In this technical solution, the voltage and current signals input to the load are collected through the sampling module, and the sampling module can use a transformer; when the load of the three-phase electricity is unbalanced, there are differences in the current and voltage of the three-phase electricity. At this time, through The switching device redi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com